Abstract

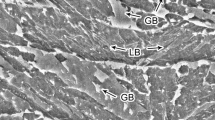

The advanced electron backscatter diffraction (EBSD) technique was used to examine the microstructure of a widely used A517GrQ low-carbon low-alloy steel after different heat treatments. Three distinguishable microstructures were studied. Slow cooling in the furnace after austenitization led to the formation of a granular structure that consisted of massive ferrite and randomly distributed M–A constituents. Medium rate cooling in air produced granular bainite that was composed of lath ferrite, and M–A constituents were distributed between the laths. Lath martensite was formed by fast cooling into ice brine. EBSD analysis revealed that, in one austenite grain, the massive ferrite in the granular structure and the lath ferrite in the granular bainite were predominately separated by high-angle boundaries, whilst the ferrite laths in the martensite were separated by low-angle boundaries. The specimens with granular bainite formed by medium rate cooling had higher strength (both yield strength and tensile strength), and also almost 5 times higher Charpy impact energy than that of the specimens containing granular structure obtained at the slow cooling. The strength of the specimens with lath martensite after quenching into ice brine was slightly higher than the granular bainite but were associated with much lower Charpy impact energy. The present work indicates that it is critical to control the cooling rate after austenitization in order to simultaneously achieve high strength and high toughness of low-carbon low-alloy steels.

Similar content being viewed by others

References

Caballero FG, Santofimia MJ, Capdevila C, García-Mateo C, De García AC (2006) Design of advanced bainitic steels by optimisation of TTT diagrams and T0 curves. ISIJ Int 46:1479–1488. https://doi.org/10.2355/isijinternational.46.1479

Hu J, Du LX, Xie H, Gao XH, Misra RDK (2014) Microstructure and mechanical properties of TMCP heavy plate microalloyed steel. Mater Sci Eng A 607:122–131. https://doi.org/10.1016/j.msea.2014.03.133

Wu BB, Huang S, Wang ZQ, Zhao JX, Wang CS, Shang CJ, Misra RDK (2019) Crystallography analysis of toughness in high strength ultra-heavy plate steel. Mater Lett 250:55–59. https://doi.org/10.1016/j.matlet.2019.04.084

Chen J, Li C, Ren J, Tu X, Chen L (2019) Strength and toughness of Fe-1.2 Mn-0.3 Cr-1.4 Ni-0.4 Mo-C tempered steel plate in three cooling processes. Mater Sci Eng A 754:178–189. https://doi.org/10.1016/j.msea.2019.03.029

Zhou T, Yu H, Wang S (2016) Effect of microstructural types on toughness and microstructural optimization of ultra-heavy steel plate: EBSD analysis and microscopic fracture mechanism. Mater Sci Eng A 658:150–158. https://doi.org/10.1016/j.msea.2016.02.001

Wang XL, Wang ZQ, Dong LL, Shang CJ, Ma XP, Subramanian SV (2017) New insights into the mechanism of cooling rate on the impact toughness of coarse grained heat affected zone from the aspect of variant selection. Mater Sci Eng, A 704:448–458. https://doi.org/10.1016/j.msea.2017.07.095

Ognianov M, Leitner H, Wieser V (2017) Influence of the cooling rate on the microstructure and mechanical properties in 5% Cr martensitic steel. Berg Huettenmaenn Monatsh 162:94–100. https://doi.org/10.1007/s00501-017-0579-6

Ali M, Porter D, Kömi J, Eissa M, El Faramawy H, Mattar T (2019) Effect of cooling rate and composition on microstructure and mechanical properties of ultrahigh-strength steels. J Iron Steel Res Int 26:1350–1365. https://doi.org/10.1007/s42243-019-00276-0

Bhadeshia HKDH (1992) Bainite in steels: transformations, microstructure and properties. Institute of Materials, London

Kang MK, Chen D, Yang S, Hu G (1992) The time-temperature-transformation diagram within the medium temperature range in some alloy steels. Metall Trans A 23:785–795. https://doi.org/10.1007/BF02675556

Zhang MX, Kang MK (1993) Strengthening-toughening mechanism of granular bainite and granular structure of low-carbon low-alloy steel. Kang T’ieh/Iron Steel (Peking) 28:51–55

Du C, Hoefnagels JPM, Vaes R, Geers MGD (2016) Block and sub-block boundary strengthening in lath martensite. Scr Mater 116:117–121. https://doi.org/10.1016/j.scriptamat.2016.01.043

Zhu K, Bouaziz O, Oberbillig C, Huang M (2010) An approach to define the effective lath size controlling yield strength of bainite. Mater Sci Eng A 527:6614–6619. https://doi.org/10.1016/j.msea.2010.06.061

Akinobu S, Nagoshi T, Masato S, Morito S, Higo Y (2010) Evaluation of the block boundary and sub-block boundary strengths of ferrous lath martensite using a micro-bending test. Mater Sci Eng, A 527:7538–7544. https://doi.org/10.1016/j.msea.2010.08.026

Morito S, Oh-ishi K, Hono K, Ohba T (2011) Carbon enrichment in retained austenite films in low carbon lath martensite steel. ISIJ Int 51:1200–1202. https://doi.org/10.2355/isijinternational.51.1200

Morito S, Ohba T, Das AK, Hayashi T, Yoshida M (2013) Effect of solution carbon and retained austenite films on the development of deformation structures of low-carbon lath martensite. ISIJ Int 53:2226–2232. https://doi.org/10.2355/isijinternational.53.2226

Suikkanen PP, Cayron C, DeArdo AJ, Pentti Karjalainen L (2013) Crystallographic analysis of isothermally transformed bainite. J Mater Sci Technol 4:359–366. https://doi.org/10.1016/j.jmst.2013.01.015

Zhang MX, Kelly PM (2002) Accurate orientation relationship between ferrite and austenite in low carbon martensite and granular bainite. Scr Mater 47:749–755. https://doi.org/10.1016/S1359-6462(02)00196-3

Kelly PM, Zhang MX (1999) Edge-to-edge matching—a new approach to the morphology and crystallography of precipitates. Mater Forum 23:41–62

Yen HW, Chen PY, Huang CY, Yang JR (2011) Interphase precipitation of nanometer-sized carbides in a titanium-molybdenum-bearing low-carbon steel. Acta Mater 59:6264–6274. https://doi.org/10.1016/j.actamat.2011.06.037

Shukla R, Ghosh SK, Chakrabarti D, Chatterjee S (2013) Microstructure, texture, property relationship in thermo-mechanically processed ultra-low carbon microalloyed steel for pipeline application. Mater Sci Eng A 587:201–208. https://doi.org/10.1016/j.msea.2013.08.054

Li J, Sun F, Xu WC (1990) On the evaluation of yield strength for microalloyed steels. Scr Metall Mater 24:1393–1398. https://doi.org/10.1016/0956-716X(90)90362-K

Zhang MX, Kelly PM (1998) Determination of carbon content in bainitic ferrite and carbon distribution in austenite by using CBKLDP. Mater Charact 40:159–168. https://doi.org/10.1016/S1044-5803(98)00005-9

Hansen N (2004) Hall-Petch relation and boundary strengthening. Scr Mater 51:801–806. https://doi.org/10.1016/j.scriptamat.2004.06.002

Mazaheri Y, Kermanpur A, Najafizadeh A (2015) Strengthening mechanisms of ultrafine grained dual phase steels developed by new thermomechanical processing. ISIJ Int 55:218–226. https://doi.org/10.2355/isijinternational.55.218

Bailey JE, Hirsch PB (1960) The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos Mag 5:485–497. https://doi.org/10.1080/14786436008238300

Moussa C, Bernacki M, Besnard R, Bozzolo N (2017) Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 179:63–72. https://doi.org/10.1016/j.ultramic.2017.04.005

Lan L, Qiu C, Zhao D, Gao X, Du L (2011) Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel. Mater Sci Eng A 529:192–200. https://doi.org/10.1016/j.msea.2011.09.017

Navarro Lopez A, Hidalgo Garcia J, Sietsma J, Santofimia Navarro MJ (2017) Characterization of bainitic/martensitic structures formed in isothermal treatments below the Ms temperature. Mater Charact 128:248–256. https://doi.org/10.1016/j.matchar.2017.04.007

Curry DA, Knott JF (1979) Effect of microstructure on cleavage fracture toughness of quenched and tempered steels. Metal Sci 13:341–345. https://doi.org/10.1179/msc.1979.13.6.341

Xiong XC, Chen B, Huang MX, Wang JF, Wang L (2013) The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Scr Mater 68:321–324. https://doi.org/10.1016/j.scriptamat.2012.11.003

Zhou Q, Qian L, Tan J, Meng J, Zhang F (2013) Inconsistent effects of mechanical stability of retained austenite on ductility and toughness of transformation-induced plasticity steels. Mater Sci Eng A 578:370–376. https://doi.org/10.1016/j.msea.2013.04.096

Kang MK, Guan DH, Guo CD, Zhu JR (1979) M–A constituents in low alloy high strength steels. Phys Test Chem Anal A 5:2+1–11+18

Acknowledgements

The authors are very grateful to HBIS project and the University of Queensland UQRT scholarship for funding support and would also like to acknowledge the support of MA at the Centre for Microscopy and Microanalysis at the University of Queensland.

Author information

Authors and Affiliations

Contributions

GL was involved in conceptualization, methodology, investigation, validation, data curation, and writing—original draft. QT helped in data curation and investigation. YL contributed to data curation, methodology and investigation. TW was involved in methodology and validation. XY helped in investigation and resources. ZT contributed to resources, AA was involved in conceptualization, supervision, and writing—review and editing. M-XZ helped in conceptualization, supervision, methodology, project administration, and writing-review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Nathan Mara.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, G., Tan, Q., Liu, Y. et al. Effect of cooling rate on microstructure and mechanical properties of a low-carbon low-alloy steel. J Mater Sci 56, 3995–4005 (2021). https://doi.org/10.1007/s10853-020-05483-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05483-9