Abstract

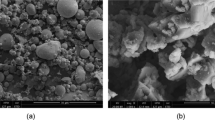

This research investigated the effects of multi-walled carbon nanotubes (MWCNTs) on the chemistry, microstructure, phase distribution, and fracture response of potassium-based metakaolin geopolymers at the microscopic scale. We formulated novel protocols to cast geopolymers reinforced with 0.3, 0.6, and 1.5 wt% MWCNTs. We studied the chemistry using XRD, FTIR, and solid state \(^{29}\)Si NMR. We characterized the microstructure and dispersion state of MWCNTs geopolymers using microscopic imaging and high-resolution scanning electron microscopy. We assessed the fracture behavior and mechanical properties using scratch tests and indentation tests. We used cluster analysis of indentation results to study the phase distribution. MWCNTs were well dispersed with an average accumulated area less than 8.9 \(\mu \hbox {m}^{2}\). XRD showed that MWCNTs preserved the amorphous phase. NMR showed that the addition of MWCNTs decreased \(\hbox {Q}^{4}\)(Al2) fraction, but increased \(\hbox {Q}^{4}\)(Al3) fraction. We observed a densification of the microstructure and a reduction in porosity. The microstructure showed that MWCNTs acted as bridges for fracture surfaces and connections for pores. The addition of 0.6 wt% MWCNTs increased the strength by 3.2%, and stiffness by 11.1%. Meanwhile, the addition of 1.5 wt% MWCNTs addition increased the fracture toughness by 10.5%. An inner strengthening effect was observed as MWCNTs reduced the microporosity, resulting in an increase in the indentation modulus and hardness for the dominant microphase. Therefore, MWCNTs promote the geopolymerization reaction, strengthen the geopolymer skeleton, affect the pore structure, and improve mechanical characteristics.

Graphical abstract

Similar content being viewed by others

References

Davidovits J (1991) Geopolymers. J Therm Anal 37:1633–1656. https://doi.org/10.1007/bf01912193

Norton MG, Provis JL (2020) 1000 at 1000: Geopolymer technology—the current state of the art. J Mater Sci 55:13487–13489. https://doi.org/10.1007/s10853-020-04990-z

Ribero D, Kriven WM (2016) Properties of Geopolymer composites reinforced with basalt chopped strand mat or woven fabric. J Am Ceram Soc 99:1192–1199. https://doi.org/10.1111/jace.14079

Duxson P, Fernández-Jiménez A, Provis JL et al (2007) Geopolymer technology: the current state of the art. J Mater Sci 42:2917–2933. https://doi.org/10.1007/s10853-006-0637-z

Bernal SA, Rodrı ED, Provis JL, Delvasto S (2012) Activation of metakaolin / slag blends using alkaline solutions based on chemically modified silica fume and rice husk ash. Waste Biomass Valor 3:99–108. https://doi.org/10.1007/s12649-011-9093-3

Lecomte I, Henrist C, Li M et al (2006) (Micro)-structural comparison between geopolymers, alkali-activated slag cement and Portland cement. J Eur Ceram Soc 26:3789–3797. https://doi.org/10.1016/j.jeurceramsoc.2005.12.021

Li J, Zhang W, Li C, Monteiro PJM (2020) Eco-friendly mortar with high-volume diatomite and fly ash: Performance and life-cycle assessment with regional variability. J Clean Prod 261:121224. https://doi.org/10.1016/j.jclepro.2020.121224

Li J, Zhang W, Li C, Monteiro PJM (2019) Green concrete containing diatomaceous earth and limestone: workability, mechanical properties, and life-cycle assessment. J Clean Prod 223:662–679. https://doi.org/10.1016/j.jclepro.2019.03.077

Rocha S, Dias DP, César F et al (2018) Metakaolin-based geopolymer mortars with different alkaline activators. Constr Build Mater 178:453–461. https://doi.org/10.1016/j.conbuildmat.2018.05.172

Mendes B, Klaus I, José A et al (2021) Assessment of mechanical and microstructural properties of geopolymers produced from metakaolin, silica fume, and red mud. Int J Appl Ceram Technol 18:262–274. https://doi.org/10.1111/ijac.13635

Němeček J, Šmilauer V, Kopecký L (2011) Nanoindentation characteristics of alkali-activated aluminosilicate materials. Cem Concr Compos 33:163–170. https://doi.org/10.1016/j.cemconcomp.2010.10.005

Fernandez-Jimenez A, García-Lodeiro I, Palomo A (2007) Durability of alkali-activated fly ash cementitious materials. J Mater Sci 42:3055–3065. https://doi.org/10.1007/s10853-006-0584-8

Shi C, Roy D, Krivenko P (2003) Alkali-activated cements and concretes. CRC Press, London,. https://doi.org/10.1201/9781482266900

Wallah SE, Rangan BV (2006) Low-calcium fly ash-based geopolymer concrete: long-term properties. Res Rep GC

Provis JL, van Deventer JSJ (2009). Geopolymers: structures, processing, properties and industrial applications. 1st ed., Woodhead Publishing Ltd

Saafi M, Andrew K, Tang PL et al (2013) Multifunctional properties of carbon nanotube/fly ash geopolymeric nanocomposites. Constr Build Mater 49:46–55. https://doi.org/10.1016/j.conbuildmat.2013.08.007

Tay YWD, Panda B, Paul SC et al (2017) 3D printing trends in building and construction industry: a review. Virtual Phys Prototyp 12:261–276. https://doi.org/10.1080/17452759.2017.1326724

Panda B, Unluer C, Tan MJ (2018) Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem Concr Compos 94:307–314. https://doi.org/10.1016/j.cemconcomp.2018.10.002

Su Z, Hou W, Sun Z (2020) Recent advances in carbon nanotube-geopolymer composite. Constr Build Mater 252:118940. https://doi.org/10.1016/j.conbuildmat.2020.118940

Senatov FS, Niaza KV, Stepashkin AA, Kaloshkin SD (2016) Low-cycle fatigue behavior of 3d-printed PLA-based porous scaffolds. Compos Part B Eng 97:193–200. https://doi.org/10.1016/j.compositesb.2016.04.067

Akono A (2020) Fracture behavior of metakaolin-based geopolymer reinforced with carbon nanofibers. Int J Ceram Eng Sci 2:234–242. https://doi.org/10.1002/ces2.10060

Chiappone A, Roppolo I, Naretto E et al (2017) Study of graphene oxide-based 3D printable composites: effect of the in situ reduction. Compos Part B Eng 124:9–15. https://doi.org/10.1016/j.compositesb.2017.05.049

Dul S, Fambri L, Pegoretti A (2016) Fused deposition modelling with ABS-graphene nanocomposites. Compos Part A Appl Sci Manuf 85:181–191. https://doi.org/10.1016/j.compositesa.2016.03.013

Han Y, Wang FK, Wang H et al (2018) High-strength boehmite-acrylate composites for 3D printing: reinforced filler-matrix interactions. Compos Sci Technol 154:104–109. https://doi.org/10.1016/j.compscitech.2017.10.026

Chen Y, Mao J, Wu J (2018) Microwave transparent crosslinked polystyrene nanocomposites with enhanced high voltage resistance via 3D printing bulk polymerization method. Compos Sci Technol 157:160–167. https://doi.org/10.1016/j.compscitech.2018.01.041

Nguyen QT, Ngo T, Tran P et al (2016) Fire performance of prefabricated modular units using organoclay/glass fibre reinforced polymer composite. Constr Build Mater 129:204–215. https://doi.org/10.1016/j.conbuildmat.2016.10.100

Dresselhaus MS, Dresselhaus G, Avouris P (Eds.) (2000) Carbon nanotubes: synthesis, structure, properties, and applications. Springer, Berlin

Huang X, Liang W, Zhang S (2011) Radial corrugations of multi-walled carbon nanotubes driven by inter-wall nonbonding interactions. Nanoscale Res Lett 6:1–6. https://doi.org/10.1007/s11671-010-9801-0

da Luz G, Gleize PJP, Batiston ER, Pelisser F (2019) Effect of pristine and functionalized carbon nanotubes on microstructural, rheological, and mechanical behaviors of metakaolin-based geopolymer. Cem Concr Compos 104:103332. https://doi.org/10.1016/j.cemconcomp.2019.05.015

Chougan M, Hamidreza Ghaffar S, Jahanzat M et al (2020) The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr Build Mater 250:118928. https://doi.org/10.1016/j.conbuildmat.2020.118928

Ngo TD, Kashani A, Imbalzano G et al (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Abbasi SM, Ahmadi H, Khalaj G, Ghasemi B (2016) Microstructure and mechanical properties of a metakaolinite-based geopolymer nanocomposite reinforced with carbon nanotubes. Ceram Int 42:15171–15176. https://doi.org/10.1016/j.ceramint.2016.06.080

Yuan J, He P, Jia D et al (2017) In situ processing of MWCNTs/leucite composites through geopolymer precursor. J Eur Ceram Soc 37:2219–2226. https://doi.org/10.1016/j.jeurceramsoc.2017.01.008

Khayamdar M, Khoramishad H (2021) The effect of metallic fiber geometry and multi-walled carbon nanotubes on the mechanical behavior of aluminum fiber-reinforced composite adhesive joints. Proc Inst Mech Eng Part L J Mater Des Appl 235(5):949–957. https://doi.org/10.1177/1464420720981404

Khoramishad H, Zarifpour D (2018) Fracture response of adhesive joints reinforced with aligned multi-walled carbon nanotubes using an external electric field. Theor Appl Fract Mech 98:220–229.

Ashofteh RS, Khoramishad H (2019) The influence of hygrothermal ageing on creep behavior of nanocomposite adhesive joints containing multi-walled carbon nanotubes and graphene oxide nanoplatelets. Int J Adhes Adhes 94:1–12. https://doi.org/10.1016/j.ijadhadh.2019.03.017

Khoramishad H, Khayamdar M (2016) Toughening epoxy adhesives with multi-walled carbon nanotubes. J Adhesion 94. https://doi.org/10.1080/00218464.2016.1224184

Gholami R, Khoramishad H, da Silva LFM (2020) Glass fiber-reinforced polymer nanocomposite adhesive joints reinforced with aligned carbon nanofillers. Compos Struct 253:112814. https://doi.org/10.1016/j.compstruct.2020.112814

Chen J, Akono AT (2020) Influence of multi-walled carbon nanotubes on the hydration products of ordinary Portland cement paste. Cem Concr Res 137:106197. https://doi.org/10.1016/j.cemconres.2020.106197

Rovnaník P, Šimonová H, Topolář L et al (2016) Effect of carbon nanotubes on the mechanical fracture properties of fly ash geopolymer. Procedia Eng 151:321–328. https://doi.org/10.1016/j.proeng.2016.07.360

Lizcano M, Kim HS, Basu S, Radovic M (2012) Mechanical properties of sodium and potassium activated metakaolin-based geopolymers. J Mater Sci 47:2607–2616. https://doi.org/10.1007/s10853-011-6085-4

Zhang P, Wang K, Wang J et al (2020) Mechanical properties and prediction of fracture parameters of geopolymer/alkali-activated mortar modified with PVA fiber and nano-SiO2. Ceram Int 46:20027–20037. https://doi.org/10.1016/j.ceramint.2020.05.074

Khater HM, Abd El Gawaad HA (2016) Characterization of alkali activated geopolymer mortar doped with MWCNT. Constr Build Mater 102:329–337. https://doi.org/10.1016/j.conbuildmat.2015.10.121

Chen X, Mondal P (2020) Effects of NaOH amount on condensation mechanism to form aluminosilicate, case study of geopolymer gel synthesized via sol-gel method. J Sol-Gel Sci Technol 96:589–603. https://doi.org/10.1007/s10971-020-05360-6

Pegel S, Pötschke P, Villmow T et al (2009) Spatial statistics of carbon nanotube polymer composites. Polymer Guildf 50:2123–2132. https://doi.org/10.1016/j.polymer.2009.02.030

ASTM International: ASTM C20-00(2015), standard test methods for apparent porosity, water absorption, apparent specific gravity, and bulk density of burned refractory brick and shapes by boiling water. https://www.astm.org/Standards/C20.htm

Théréné F, Keita E, Nael-Redolfi J, Boustingorry P, Bonafous L, Roussel N (2020) Water absorption of recycled aggregates: Measurements, influence of temperature and practical consequences. Cem Concr Res 137:106196–106204

Abdel-Ghani NT (2014) Individual and competitive adsorption of phenol and nickel onto multiwalled carbon nanotubes. J Adv Res. https://doi.org/10.1016/j.jare.2014.06.001

Atchudan R, Pandurangan A, Joo J (2015). Effects of nanofillers on the thermo-mechanical properties and chemical resistivity of epoxy nanocomposites. https://doi.org/10.1166/jnn.2015.9706

Nie P, Min C, Song HJ, Chen X, Zhang Z, Zhao K (2016). Preparation and tribological properties of polyimide / carboxyl-functionalized preparation and tribological properties of polyimide/carboxyl- functionalized multi-walled carbon nanotube nanocomposite films under seawater lubrication. https://doi.org/10.1007/s11249-015-0476-7

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583. https://doi.org/10.1557/JMR.1992.1564

Sorelli L, Constantinides G, Ulm FJ, Toutlemonde F (2008) The nano-mechanical signature of ultra high performance concrete by statistical nanoindentation techniques. Cem Concr Res 38:1447–1456. https://doi.org/10.1016/j.cemconres.2008.09.002

Akono AT, Randall NX, Ulm FJ (2012) Experimental determination of the fracture toughness via microscratch tests: application to polymers, ceramics, and metals. J Mater Res 27:485–493. https://doi.org/10.1557/jmr.2011.402

Akono AT, Ulm FJ (2014) An improved technique for characterizing the fracture toughness via scratch test experiments. Wear 313:117–124. https://doi.org/10.1016/j.wear.2014.02.015

Kendall AK, Howard AJ, Birchall JD et al (1983) The relation between porosity, microstructure and strength, and the approach to advanced cement-based materials and discussion, Philos Trans Royal Soc London. Ser A Math and Phys Sci A310:139–153

Rice RW (1999) Effects of amount, location, and character of porosity on stiffness and strength of ceramic fiber composites via different processing. J Mater Sci 34:2769–2772. https://doi.org/10.1023/A:1004606612294

Akono AT, Koric S, Kriven WM (2019) Influence of pore structure on the strength behavior of particle- and fiber-reinforced metakaolin-based geopolymer composites. Cem Concr Compos 104:103361. https://doi.org/10.1016/j.cemconcomp.2019.103361

Nash SG (2000) A survey of truncated-Newton methods. J Comput Appl Math 124:45–59. https://doi.org/10.1016/S0377-0427(00)00426-X

Michie D (1968) “Memo” functions and machine learning. Nature 218:19–22. https://doi.org/10.1038/218019a0

Akono A, Kabir P (2016) Nano-Scale Characterization of Organic-Rich Shale via Indentation Methods, New frontiers in oil and gas exploration. New Front Oil Gas Explor 40124. https://doi.org/10.1007/978-3-319-40124-9

Constantinopoulos C, Titsias MK, Likas A (2006) Bayesian feature and model selection for Gaussian mixture models. IEEE Trans Pattern Anal Mach Intell 28:1013–1018. https://doi.org/10.1109/TPAMI.2006.111

Rasmussen CE (2000) The infinite Gaussian mixture model. Adv Neural Inf Process Syst 554–559

Chellappa R, Veeraraghavan A, Ramanathan N (2009) Gaussian mixture models. Encycl Biom 659–663.

Vila JP, Schniter P (2013) Expectation-maximization Gaussian-mixture approximate message passing. IEEE Trans Signal Process 61:4658–4672. https://doi.org/10.1109/TSP.2013.2272287

Lee WKW, Van Deventer JSJ (2003) Use of infrared spectroscopy to study geopolymerization of heterogeneous amorphous aluminosilicates. Langmuir 19:8726–8734. https://doi.org/10.1021/la026127e

Rees CA, Provis JL, Lukey GC, Van Deventer JSJ (2007) In situ ATR-FTIR study of the early stages of fly ash geopolymer gel formation. Langmuir 23:9076–9082. https://doi.org/10.1021/la701185g

Davidovits, J. (2015) Geopolymer chemistry and applications. 5-th ed. Geopolymer Institute, Saint-Quentin, France

Zhang DW, Min Wang D, Lin XQ, Zhang T (2018) The study of the structure rebuilding and yield stress of 3D printing geopolymer pastes. Constr Build Mater 184:575–580. https://doi.org/10.1016/j.conbuildmat.2018.06.233

Archez J, Texier-mandoki N, Bourbon X et al (2021) Shaping of geopolymer composites by 3D printing. J Build Eng 34:101894. https://doi.org/10.1016/j.jobe.2020.101894

Panda B, Unluer C, Tan MJ (2019) Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing. Compos Part B Eng 176:107290. https://doi.org/10.1016/j.compositesb.2019.107290

Chen S, Wu C, Yan D (2019) Binder-scale creep behavior of metakaolin-based geopolymer. Cem Concr Res 124:105810. https://doi.org/10.1016/j.cemconres.2019.105810

Si R, Guo S, Dai Q, Wang J (2020) Atomic-structure, microstructure and mechanical properties of glass powder modified metakaolin-based geopolymer. Constr Build Mater 254:119303. https://doi.org/10.1016/j.conbuildmat.2020.119303

Yan S, Zhang F, Li H, Gao B, Xing P, He P, Jia D, (2020) Synthesis and mechanical properties of lightweight hybrid geopolymer foams reinforced with carbon nanotubes. pp 2335–2345. https://doi.org/10.1111/ijac.13543

Zou B, Jian S, Korayem AH et al (2014) Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon N Y 85:212–220. https://doi.org/10.1016/j.carbon.2014.12.094

Zhan M, Pan G, Zhou F et al (2020) In situ-grown carbon nanotubes enhanced cement-based materials with multifunctionality. Cem Concr Compos 108:103518. https://doi.org/10.1016/j.cemconcomp.2020.103518

Chen X, Kim E et al (2020) Quantitative correlation between the degree of reaction and compressive strength of Metakaolin-based geopolymers. Materials 13:5784. https://doi.org/10.3390/ma13245784

Tsai Y, Hanna JV, Lee Y et al (2010) Journal of solid state chemistry solid-state nmr study of geopolymer prepared by sol–gel chemistry. J Solid State Chem 183:3017–3022. https://doi.org/10.1016/j.jssc.2010.10.008

Duxson P, Provis JL, Lukey GC, et al (2005) Si NMR study of structural ordering in aluminosilicate geopolymer gels, pp 3028–3036

Sankar K, Sutrisno A, Kriven WM (2019) Slag-fly ash and slag-metakaolin binders: part II-Properties of precursors and NMR study of poorly ordered phases. J Am Ceram Soc 102:3204–3227. https://doi.org/10.1111/jace.16224

Gupta R, Bhardwaj P, Deshmukh K, et al (2019) Development and characterization of inorganic-organic (Si-O-Al) hybrid geopolymeric precursors via solid state method, pp 221–232

Samuel DM, Sutrisno A, Kriven W, (2021) Relative importance of Al ( V ) and reinforcement to the flexural strength of geopolymer composites, pp 3452–3460. https://doi.org/10.1111/jace.17656

Provis JL (2006) Modelling the formation of geopolymers. Thesis 44:8–10

Acknowledgements

This material is based upon work supported by the National Science Foundation under Grant No. CMMI 1829101. In addition, we would like to acknowledge the Walter P. Murphy Fellowship that supported Jiaxin Chen during her Ph.D. studies at the Department of Civil and Environmental Engineering at Northwestern University. We would also like to acknowledge Raymonde Council and Mairi Rose Glynn. This work made use of the EPIC Facility of Northwestern University’s NUANCE Center, which has received support from the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-1542205); the MRSEC program (NSF DMR-1720139) at the Materials Research Center; the International Institute for Nanotechnology (IIN); the Keck Foundation; and the State of Illinois, through the IIN. This work made use of the Jerome B. Cohen X-Ray Diffraction Facility supported by the MRSEC program of the National Science Foundation (DMR-1720139) at the Materials Research Center of Northwestern University and the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-1542205). This work made use of the MatCI Facility supported by the MRSEC program of the National Science Foundation (DMR-1720139) at the Materials Research Center of Northwestern University. This work made use of the Keck-II facility of Northwestern University’s NUANCE Center, which has received support from the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-1542205); the MRSEC program (NSF DMR-1720139) at the Materials Research Center; the International Institute for Nanotechnology (IIN); the Keck Foundation; and the State of Illinois, through the IIN. Moreover, we want to thank BASF for providing the raw metakaolin and Wacker for providing the fumed silica.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflicts of interest.

Additional information

Handling Editor: Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, J., Akono, AT. Influence of multi-walled carbon nanotubes on the fracture response and phase distribution of metakaolin-based potassium geopolymers. J Mater Sci 56, 19403–19424 (2021). https://doi.org/10.1007/s10853-021-06547-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06547-0