Abstract

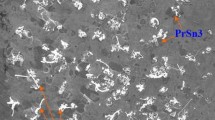

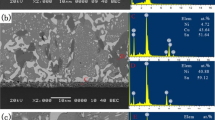

In this study, trace amount of rare earth Pr was added into Sn–0.3Ag–0.7Cu low-Ag solder to enhance properties of solders. Experimental results indicated that optimal amount of Pr addition (~0.06 wt%) can improve properties of wettability, shear force and ductility of Sn–0.3Ag–0.7Cu low-Ag solder. This is because that solder with optimal Pr addition not only had a refined microstructure but also owned a regular and thin interfacial IMC layer after soldering on Cu substrate. Meanwhile, we have explained the change of morphology and thickness of interfacial IMC layer after Pr addition based on Kim and Tu’s kinetic model of interfacial IMC growth. However, it was found excessive Pr addition led to the formation of PrSn3 phase, which was easy to be oxidized and became a great deterioration on the properties referred above. Besides, the fracture mode of solder joint also gradually changed from ductile fracture to cleavage fracture. Moreover, this oxidized PrSn3 became the birthplace of Sn whisker since it provided abundant supply of Sn sources and compressive stress for Sn whisker growth. By the in-situ observation of Sn whisker growth in 0.5 wt% Pr-doped solder joint, we obtained that the incubation period of Sn whisker is very short and its growth rate may have a great decrease with time extending. Besides, it was found after 1 day at room temperature, spindly and rod-like Sn whiskers also grew in 0.5 wt% Pr-doped solder joint besides dot-shaped Sn whisker that grew in 0.5 wt% Pr-doped solder matrix. We suggest this may be related with the extra compressive stress provided by interfacial IMC layer growth in 0.5 wt% Pr-doped solder joint.

Similar content being viewed by others

References

H.Q. Wang, H. Zhao, D.P. Sekulic, Y.Y. Qian, A comparative study of reactive wetting of lead and lead-free solders on Cu and (Cu6Sn5/Cu3Sn)/Cu substrates. J. Electron. Mater. 37(10), 1640–1647 (2008)

J.C. Xu, et al., Study on microstructure and properties of Sn-0.3Ag-0.7Cu solder bearing Nd. J. Mater. Sci. (2016). doi:10.1007/s10854-016-4901-y

J. Wang, H.M. Wei, P. He, T.S. Lin, F.J. Lu, Microstructure and mechanical properties of tin-bismuth solder reinforced by aluminum borate whiskers. J. Electron. Mater. 44(10), 3872–3879 (2015)

L. L. Gao, et al., Effects of trace rare earth Nd addition on microstructure and properties of SnAgCu solder. J. Mater. Sci. 21(7), 643–648 (2010)

L. Zhang et al., Properties enhancement of SnAgCu solders containing rare earth Yb. Mater. Des 57, 646–651 (2014)

G. Zeng et al., Interfacial microstructure and properties of Sn–0.7Cu–0.05 Ni/Cu solder joint with rare earth Nd addition. J. Alloy. Compd. 509(25), 7152–7161 (2011)

K.S. Kim, S.H. Huh, K. Suganuma, Effects of intermetallic compounds on properties of Sn–Ag–Cu lead-free soldered joints. J. Alloy. Compd. 352(1), 226–236 (2003)

L. L. Gao, et al., Effect of praseodymium on the microstructure and properties of Sn3.8Ag0.7Cu solder. J. Mater. Sci. 21(9), 910–916 (2010)

M. Osterman, M. Pecht, Strain range fatigue life assessment of lead-free solder interconnects subject to temperature cycle loading. Solder. Surf. Mt. Technol. 19(2), 12–17 (2007)

A.A. El-Daly et al., Influence of Zn addition on the microstructure, melt properties and creep behavior of low Ag-content Sn-Ag-Cu lead-free solders. Mater. Sci. Eng. A 608, 130–138 (2014)

D. X. Luo, S. B. Xue, S. Liu, Investigation on the intermetallic compound layer growth of Sn-0.5Ag-0.7Cu-xGa/Cu solder joints during isothermal aging. J. Mater. Sci. 25(12), 5195–5200 (2014)

K. Kanlayasiri, M. Mongkolwongrojn, T. Ariga, Influence of indium addition on characteristics of Sn-0.3Ag-0.7 Cu solder alloy. J. Alloy. Compd. 485(1), 225–230 (2009)

A.A. El-Daly et al., Microstructure, mechanical properties, and deformation behavior of Sn-1.0 Ag-0.5 Cu solder after Ni and Sb additions. Mater. Des. 43, 40–49 (2013)

L.C. Tsao et al., Influence of TiO2 nanoparticles addition on the microstructural and mechanical properties of Sn0.7Cu nano-composite solder. Mater. Sci. Eng. A 545, 194–200 (2012)

A.A. El-Daly et al., Novel SiC nanoparticles-containing Sn-1.0Ag-0.5 Cu solder with good drop impact performance. Mater. Sci. Eng. A 578, 62–71 (2013)

L. Zhang, K. N. Tu, Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Eng. 82, 1–32 (2014)

H.T. Lee et al., Effect of La addition on adhesive strength and fracture behavior of Sn-3.5Ag solder joints. Mater. Sci. Eng. A 528(10), 3630–3638 (2011)

L. Zhang et al., Microstructure characterization of SnAgCu solder bearing Ce for electronic packaging. Microelectron. Eng. 88(9), 2848–2851 (2011)

L. Zhang, et al., Properties and microstructures of SnAgCu-xEu alloys for concentrator silicon solar cells solder layer. Sol. Energy Mat. Sol. C 130, 397–400 (2014)

T. H. Chuang, Rapid whisker growth on the surface of Sn-3Ag-0.5 Cu-1.0 Ce solder joints. Scripta. Mater. 55(11), 983–986 (2006)

Japanese Industrial Standards Committee, JIS Z 3198-4: 2003. Test Methods For Lead-Free Solders—Part 4: Methods for Wettability Test by a Wetting Balance Method and a Contact Angle Method (2003)

Japanese Industrial Standards Committee, JIS Z 3198-7: 2003. Test Methods For Lead-Free Solders—Part 7: Methods For Shear Test Of Solder Joints On Chip Components (2003)

Solderability Tests for Component Leads, Terminations, Lugs, Terminals and Wires, IPC/EIA/JEDEC J-STD-003B, 2003

X. J. Liu, et al., Thermodynamic Calculation of phase equilibria in the Sn-Ag-Cu-Ni-Au System. J. Electron. Mater. 36(11), 1429–1441 (2007)

W. Humerothery, G. V. Raynor, Book Reviews: The Structure of Metals and Alloys. Science 120, 1–383 (1954)

M.A. Dudek, N. Chawla, Mechanisms for Sn whisker growth in rare earth-containing Pb-free solders. Acta Mater. 57(15), 4588–4599 (2009)

H.K. Kim, T.N. Tu, Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening. Phys. Rev. B 53(23), 16027–16034 (1996)

R.L. DeKock, H.B. Gray, Chemical structure and bonding (University Science Books, Sausalito, 1989), p. 91

Acknowledgements

The present work was carried out with the support of China Postdoctoral Science Foundation (General Financial Grant 2014M550289, Special Financial Grant 2015T80548). The Project was also supported by the Key Laboratory of Advanced Welding Technology of Jiangsu Province, China (JSAWT-14-04) and the Priority Academic Program Development of Jiangsu Higher Education Institutions(PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, J., Xue, S., Wang, J. et al. Effect of Pr addition on properties and Sn whisker growth of Sn–0.3Ag–0.7Cu low-Ag solder for electronic packaging. J Mater Sci: Mater Electron 28, 10230–10244 (2017). https://doi.org/10.1007/s10854-017-6790-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6790-0