Abstract

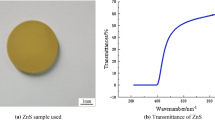

ZnS has been widely used as a material for windows in optical systems. This is because it has a good transmittance in both mid-infrared and far-infrared bands, a stable chemical performance, a moderate linear thermal expansion coefficient and an adequate mechanical strength. ZnS windows need the so-called splice technology implementation to satisfy the integrity of large size applications or special surface structures. Traditional ZnS light windows are mechanically assembled with metal frames. However, the strength of the large-size ZnS formed by mechanical assembly is low. Consequently, an adequate joining technology is needed to overcome the low splice strength and improve the mechanical strength of the assembly. In this paper, we proposed a pre-metallization method by using an electroless plating of Ni on ZnS surface. Subsequently, a low temperature joining by using a Sn63Pb37 solder was completed. By a study of the process and the corresponding mechanism of the electroless nickel plating, a Ni–P layer with a controllable P content and thickness has been formed, and a smooth surface and a good combination with ZnS has been obtained. The microstructure of the Sn63Pb37 and Ni–P/ZnS was analyzed, and the phase composition and element distribution within the joint were determined. The influences of process parameters on the microstructures of the joints have been explored, including the brazing temperature, the time of thermal energy preservation and the thickness of the coating. Finally, the shear strengths of joints under different imposed parameters were optimized leading to the peak soldering temperature of 250 °C and the dwell at the peak of 1 min. The fractures were along Ni–P/ZnS ceramic interface, therefore, a successfully low temperature joining process on ZnS ceramics using Ni–P plating and Sn63Pb37 solder had been performed.

Similar content being viewed by others

References

E. Axinte, Glasses as engineering materials: a review. Mater. Des. 32(4), 1717–1732 (2011)

A. Rogalski, J. Antoszewski, L. Faraone, Third-generation infrared photodetector arrays. J. Appl. Phys. 105(9), 4 (2009)

Z.Y. Fang, et al., Micromorphologies and defects in CVD ZnS and ZnSe, in Key Engineering Materials (Trans Tech Publications, Vol. 280, 2005)

Y. Liu, Y. He, Z. Yuan et al., Numerical and experimental study on thermal shock damage of CVD ZnS infrared window material. J. Alloy. Compd. 589(589), 101–108 (2014)

A.F. Shchurov, E.M. Gavrishchuk, V.B. Ikonnikov et al., Effect of hot isostatic pressing on the elastic and optical properties of polycrystalline CVD ZnS. Inorg. Mater. 40(4), 336–339 (2004)

I.P. Shcherbakov, A.A. Dunaev, A.E. Chmel, Effect of abrasion on the crystal structure of ZnS and ZnSe ceramics. Inorg. Mater. 54(10), 1051–1054 (2018)

F. Kurnia, Y.H. Ng, Y. Tang et al., ZnS thin films for visible-light active photoelectrodes: effect of film morphology and crystal structure. Cryst. Growth Des. 16(5), 2461–2465 (2016)

F. Wang, X. Zhang, Y. Lin et al., Structural coloration pigments based on carbon modified ZnS@ SiO2 nanospheres with low-angle dependence, high color saturation, and enhanced stability. ACS Appl. Mater. Interfaces. 8(7), 5009–5016 (2016)

R. Banerjee, Y.P. Varshni, Lattice dynamics and thermodynamic properties of β-ZnS, GaP and β-SiC. J. Phys. Soc. Jpn. 30(4), 1015–1021 (1971)

N.I. Khinev, G.M. Grebenyuk, V.G. Kanibolotskii, Effect of heat treatment on α-ZnS and β-ZnS transformations. Sov. Phys. J. 17(6), 816–819 (1974)

S.V. Nistor, M. Stefan, L.C. Nistor et al., Distribution and interaction of Mn2+ ions incorporated in cubic ZnS quantum dots over a broad concentration range. J. Alloy. Compd. 662, 193–199 (2016)

P.I. Chou, D.Q. Ng, I.C. Li et al., Effects of dissolved oxygen, pH, salinity and humic acid on the release of metal ions from PbS, CuS and ZnS during a simulated storm event. Sci. Total Environ. 624, 1401–1410 (2018)

B.H. Hwang, H.B. Xu, S.J. Park et al., Structural and optical properties of solvothermally synthesized ZnS nano-materials using Na2S·9H2O and ZnSO4·7H2O precursors. Ceram. Int. 42(10), 11700–11708 (2016)

S.Y. Chang, T.H. Chuang, L.C. Tsao et al., Active soldering of ZnS–SiO2 sputtering targets to copper backing plates using an Sn3·5Ag4Ti (Ce, Ga) filler metal. J. Mater. Process. Technol. 202(1–3), 22–26 (2008)

R. Koleňák, P. Šebo, M. Provazník et al., Shear strength and wettability of active Sn3·5Ag4Ti (Ce, Ga) solder on Al2O3 ceramics. Mater. Des. 32(7), 3997–4003 (2011)

G. Sala, Advanced metal–ceramic joining techniques for orthopaedic applications, in Joining and Assembly of Medical Materials and Devices (Woodhead Publishing, Sawston, 2013), pp. 407–448

C.A. Loto, Electroless nickel plating: a review. Silicon 8(2), 177–186 (2016)

C. Gao, L. Dai, W. Meng et al., Electrochemically promoted electroless nickel-phosphorous plating on titanium substrate. Appl. Surf. Sci. 392, 912–919 (2017)

K. DeHority, N. Budin, S.S. Hilston et al., Deposition of nickel on electrodeposited Cu2O films at potentials more positive than the nernst potential of Ni2+/Ni0. J. Electrochem. Soc. 164(9), H615–H620 (2017)

M. Ranjbar, M.A. Taher, A. Sam, Mg-MOF-74 nanostructures: facile synthesis and characterization with aid of 2, 6-pyridinedicarboxylic acid ammonium. J. Mater. Sci. 27(2), 1449–1456 (2016)

M. Ranjbar, M. Salavati-Niasari, S.M. Hosseinpour-Mashkani et al., Solvothermal synthesis and characterization of hollow sphere-LIKE ZnS/ZnAl2S4 nanocomposites. J. Inorg. Organomet. Polym Mater. 22(5), 1122–1127 (2012)

P. Rajaei, M. Ranjbar, Synthesis and characterization of zinc oxide nanostructures by green capping agent and its photocatalytic degradation of methylene blue (MB). J. Mater. Sci. 27(2), 1708–1712 (2016)

C. Li, X. Zhang, Y. Chen et al., Understanding the residual stress distribution through the thickness of atmosphere plasma sprayed (APS) thermal barrier coatings (TBCs) by high energy synchrotron XRD; digital image correlation (DIC) and image based modelling. Acta Mater. 132, 1–12 (2017)

C. Li, S.D.M. Jacques, Y. Chen et al., Precise strain profile measurement as a function of depth in thermal barrier coatings using high energy synchrotron X-rays. Scr. Mater. 113, 122–126 (2016)

C. Li, X. Si, L. Chen et al., Non-destructive measurement of residual stress distribution as a function of depth in sapphire/Ti6Al4 V brazing joint via Raman spectra. Ceram. Int. 45(3), 3284–3289 (2019)

H. Bian, Y. Song, D. Liu, et al., Joining of SiO2 ceramic and TC4 alloy by nanoparticles modified brazing filler metal. Chin. J. Aeronaut. (2019)

H. Bian, X. Song, S. Hu et al., Microstructure evolution and mechanical properties of titanium/alumina brazed joints for medical implants. Metals 9(6), 644 (2019)

V.N. Kuleshov, N.V. Kuleshov, S.A. Grigoriev et al., Development and characterization of new nickel coatings for application in alkaline water electrolysis. Int. J. Hydrog. Energy 41(1), 36–45 (2016)

B. Attard, A. Leyland, A. Matthews et al., Improving the surface characteristics of Ti–6Al–4V and Ti metal 834 using PIRAC nitriding treatments. Surf. Coat. Technol. 339, 208–223 (2018)

J.N. Pang, S.W. Jiang, H. Lin et al., Significance of sensitization process in electroless deposition of Ni on nanosized Al2O3 powders. Ceram. Int. 42(3), 4491–4497 (2016)

A. Kaewvilai, R. Tanathakorn, A. Laobuthee et al., Electroless copper plating on nano-silver activated glass substrate: a single-step activation. Surf. Coat. Technol. 319, 260–266 (2017)

F. Huang, H. Zhang, J.F. Banfield, Two-stage crystal-growth kinetics observed during hydrothermal coarsening of nanocrystalline ZnS. Nano Lett. 3(3), 373–378 (2003)

J. Huang, Z. Sun, F. Zhou et al., Method for electroless nickel plating on poly (ethylene terephthalate) substrates and through holes modified with primer. J. Mater. Sci. 28(15), 10974–10980 (2017)

J. Murata, K. Yodogawa, K. Ban, Polishing-pad-free electrochemical mechanical polishing of single-crystalline SiC surfaces using polyurethane: CeO2 core–shell particles. Int. J. Mach. Tools Manuf. 114, 1–7 (2017)

B.S. Moon, S. Kim, H.E. Kim et al., Hierarchical micro-nano structured Ti6Al4V surface topography via two-step etching process for enhanced hydrophilicity and osteoblastic responses. Mater. Sci. Eng. C 73, 90–98 (2017)

F.J. Pérez-Alonso, C. Adán, S. Rojas et al., Ni–Co electrodes prepared by electroless-plating deposition. A study of their electrocatalytic activity for the hydrogen and oxygen evolution reactions. Int. J. Hydrog. Energy 40(1), 51–61 (2015)

Z. Huang, T.T. Nguyen, Y. Zhou, et al., A low temperature electroless nickel plating chemistry. Surf. Coat. Technol. (2019)

C.S. Chang, K.H. Hou, M.D. Ger et al., Effects of annealing temperature on microstructure, surface roughness, mechanical and tribological properties of Ni–P and Ni–P/SiC films. Surf. Coat. Technol. 288, 135–143 (2016)

D. Wang, L.B. Kong, M.C. Liu et al., Amorphous Ni–P materials for high performance pseudocapacitors. J. Power Sources 274, 1107–1113 (2015)

J. Wojewoda-Budka, A. Wierzbicka-Miernik, L. Litynska-Dobrzynska et al., Microstructure characteristics and phase transformations of the Ni–P and Ni–P–Re electroless deposited coatings after heat treatment. Electrochim. Acta 209, 183–191 (2016)

C. Xu, L. Chen, L. Yu et al., Effect of pickling processes on the microstructure and properties of electroless Ni–P coating on Mg–7.5 Li–2Zn–1Y alloy. Prog. Nat. Sci. 24(6), 655–662 (2014)

M.K. Beyer, H. Clausen-Schaumann, Mechanochemistry: the mechanical activation of covalent bonds. Chem. Rev. 105(8), 2921–2948 (2005)

A.N. Alhazaa, T.I. Khan, Diffusion bonding of Al7075 to Ti–6Al–4V using Cu coatings and Sn–36 Ag–1Cu interlayers. J. Alloys Compd. 494(1–2), 351–358 (2010)

Z. Shuye, X. Xu, T. Lin, P. He, Recent advances in nano-materials for packaging of electronic devices. J. Mater. Sci. (2019). https://doi.org/10.1007/s10854-019-01790-3

Y.S. Yang, C.J. Yang, F.Y. Ouyang, Interfacial reaction of Ni3Sn4 intermetallic compound in Ni/SnAg solder/Ni system under thermomigration. J. Alloy. Compd. 674, 331–340 (2016)

H.C. Cheng, R.Y. Hong, H.C. Hu et al., Role of plastic behaviors of Ni3Sn4 intermetallic compound on solder joint reliability. IEEE Trans. Dev. Mater. Reliab. 18(1), 18–26 (2018)

H. Ji, M. Li, S. Ma et al., Ni3Sn4-composed die bonded interface rapidly formed by ultrasonic-assisted soldering of Sn/Ni solder paste for high-temperature power device packaging. Mater. Des. 108, 590–596 (2016)

T. Maeshima, H. Ikehata, K. Terui et al., Effect of Ni to the Cu substrate on the interfacial reaction with Sn–Cu solder. Mater. Des. 103, 106–113 (2016)

A. Pineau, A.A. Benzerga, T. Pardoen, Failure of metals I: brittle and ductile fracture. Acta Mater. 107, 424–483 (2016)

Acknowledgement

This research is supported by “National Natural Science Foundation of China (NSFC, Grant Number 51805115)”, “China Postdoctoral Science Foundation funded Project (2019M651280)”.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, S., Qi, X., Xu, X. et al. Effects of electroless nickel plating method for low temperature joining ZnS ceramics. J Mater Sci: Mater Electron 30, 15236–15249 (2019). https://doi.org/10.1007/s10854-019-01896-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01896-8