Abstract

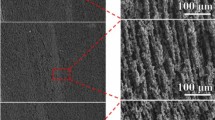

A solid freeform fabrication technique, freeze extrusion fabrication (FEF), was investigated for the creation of three-dimensional bioactive glass (13–93) scaffolds with pre-designed porosity and pore architecture. An aqueous mixture of bioactive glass particles and polymeric additives with a paste-like consistency was extruded through a narrow nozzle, and deposited layer-by-layer in a cold environment according to a computer-aided design (CAD) file. Following sublimation of the ice in a freeze dryer, the construct was heated according to a controlled schedule to burn out the polymeric additives (below ~500°C), and to densify the glass phase at higher temperature (1 h at 700°C). The sintered scaffolds had a grid-like microstructure of interconnected pores, with a porosity of ~50%, pore width of ~300 μm, and dense glass filaments (struts) with a diameter or width of ~300 μm. The scaffolds showed an elastic response during mechanical testing in compression, with an average compressive strength of 140 MPa and an elastic modulus of 5–6 GPa, comparable to the values for human cortical bone. These bioactive glass scaffolds created by the FEF method could have potential application in the repair of load-bearing bones.

Similar content being viewed by others

References

Wolff J. The law of bone remodeling, translated from the 1982 original Das Gesetz der Transformation der Knochen, by P. Maquet and R. Furlong. Springer Verlag: Berlin, Heidelberg, New York; 1986.

Woesz A. Rapid prototyping to produce porous scaffolds with controlled architecture for possible use in bone tissue engineering. In: Bidanda B, Bártolo P, editors. Virtual prototyping and bio manufacturing in medical applications. New York: Springer; 2008. p. 171–206.

Mikhael MM. Failure of metal-on-metal total hip arthroplasty mimicking hip infection. J Bone Joint Surg. 2009;91-A:443–6.

Pandit H, Glyn-jones S, McLardy-Smith P, Gundle R, Whitwell D, Gibbons CLM, Ostlere S, Athanasou N, Gill HS, Murray DW. Pseudotumours associated with metal-on-metal hip resurfacings. J Bone Joint Surg Br. 2008;90B:847–51.

Tsuruga E, Takita H, Itoh H, Wakisaka Y, Kuboki Y. Pore size of porous hydroxyapatite as the cell-substratum controls BMP-induced osteogenesis. J Biochem. 1997;121:317–24.

Rezwan K, Chen QZ, Blaker JJ, Boccaccinni AR. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials. 2006;27:3413–31.

Guarino V, Causa F, Ambrosio L. Bioactive scaffolds for bone and ligament tissue. Expert Rev Med Devices. 2007;4:405–18.

Ma PX. Scaffolds for tissue fabrication. Mater Today. 2004;7:30–40.

Chen Q, Roether JA, Boccaccinni AR. Tissue engineering scaffolds from bioactive glass and composite materials. Topics Tissue Eng. 2008;4:1–27.

Bergsma EJ, Rozema FR, Bos RRM, Debruijn WC. Foreign body reaction to resorbable poly(l-lactide) bone plates and screws used for the fixation of unstable zygomatic fractures. J Oral Maxillofac Surg. 1993;51:666–70.

Martin C, Winet H, Bao JY. Acidity near eroding polylactide–polyglycolide in vitro and in vivo in rabbit tibia bone chambers. Biomaterials. 1996;17:2373–80.

Hench LL, Polak JM, Buttery Lee DK, Xynos ID, Maroothynaden J. Use of bioactive glass composites to stimulate osteoblast production. US Patent No. 0009598A1; Jan 2004

Hench LL, Polak JM. Third-generation biomaterials. Science. 2002;295:1014–7.

Fu Q, Rahaman MN, Bal SB, Brown RF, Day DE. Mechanical and in vitro performance of 13–93 bioglass scaffolds prepared by polymer foam replication technique. Acta Biomater. 2008;4:1854–64.

Fu Q, Rahaman MN, Bal SB, Brown RF. Preparation and in vitro evaluation of bioactive glass (13–93) scaffolds with oriented microstructures for repair and regeneration of load-bearing bones. J Biomed Mater Res Part A. 2010;93A:1380–90.

Sepulveda P, Jones JR, Hench LL. Bioactive sol–gel foams for tissue repair. J Biomed Mater Res. 2002;59:340–8.

Ma PX, Choi JW. Biodegradable polymer scaffolds with well-defined interconnected spherical pore network. Tissue Eng. 2001;7:23–33.

Lu HH, El-Amin SF, Scott KD, Laurencin CT. Three dimensional, bioactive, biodegradable, polymer-bioactive glass composite scaffolds with improved mechanical properties support collagen synthesis and mineralization of human osteoblast-like cells in vitro. J Biomed Mater Res Part A. 2003;64:465–74.

Cesarano J, Calvert PD. Freeforming objects with low-binder slurry. US Patent Number 6027326; Feb 2000

Smay JE, Gratson GM, Shepherd RF, Cesarano J, Lewis JA. Directed colloidal assembly of 3D periodic structures. Adv Mater. 2002;14:1279–83.

Smay JE, Cesarano J, Lewis JA. Colloidal inks for directed assembly of 3D periodic structures. Langmuir. 2002;18:5429–37.

Michna S, Willie W, Lewis JA. Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds. Biomaterials. 2005;26:5632–9.

Miranda P, Saiz E, Gryn K, Tomsia AP. Sintering and robocasting of β-tricalcium phosphate scaffolds for orthopedic applications. Acta Biomater. 2006;2:457–66.

Russias J, Saiz E, Deville S, Gryn K, Liu G, Nalla RK, Tomsia AP. Fabrication and in vitro characterization of three-dimensional organic/inorganic scaffolds by robocasting. J Biomed Mater Res Part A. 2007;83A:434–45.

Hollinger JO, Leong K. Poly(alpha-hydroxy acids): carriers for bone morphogenetic proteins. Biomaterials. 1996;17:187–94.

Hu YH, Grainger DW, Winn SR, Hollinger JO. Fabrication of poly(-hydroxy acid) foam scaffolds using multiple solvent systems. J Biomed Mater Res. 2002;59:563–72.

Hutmacher DW. Scaffolds in tissue engineering bone and cartilage. Biomaterials. 2000;21:2529–43.

Burg KJL, Porter S, Kellam JF. Biomaterial developments for bone tissue engineering. Biomaterials. 2000;21:2347–59.

Deville S, Saiz E, Tomsia AP. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials. 2006;27:5480–9.

Fung YC. Biomechanics mechanical properties of living tissues. New York: Springer; 1993. p. 500.

Keaveny TM, Hayes WC. Mechanical properties of cortical bone and trabecular bone. In: Hall BK, editor. Bone growth. Boca Racon, FL: CRC press; 1993. p. 285–344.

Rho J-Y. Mechanical properties and the hierarchical structure of bone. Med Eng Phys. 1998;20:92–102.

Russias J, Saiz E, Deville S, Gryn K, Liu G, Nalla RK, Tomsia AP. Fabrication and in vitro characterization of three-dimensional organic/inorganic scaffolds by robocasting. J Biomed Mater Res Part A. 2007;83A:434–45.

Cowin SC. Bone mechanics handbook. 2nd ed. London UK: Informa Healthcare; 2001. p. 101–1023.

Miranda P, Pajares A, Saiz E, Tomsia AP, Guiberteau F. Fracture modes under uniaxial compression in hydroxyapatite scaffolds fabricated by robocasting. J Biomed Mater Res, Part B Appl Biomater. 2007;83A:646–55.

Miranda P, Pajares A, Saiz E, Tomsia AP, Guiberteau F. Mechanical properties of calcium phosphate scaffolds fabricated by robocasting. J Biomed Mater Res Part A. 2008;85A:218–27.

Lorrison JC, Goodridge RD, Dalgarno KW, Wood DJ. Selective laser sintering of bioactive glass-ceramics, Solid Freeform Fabrication Proceedings. University of Texas at Austin; 2002, pp. 1–8

Lorrison JC, Dalgarno KW, Wood DJ. Processing of an apatite-mullite glass-ceramic and an hydroxyapatite/phosphate glass composite by selective laser sintering. J Mater Sci Mater Med. 2005;16:775–81.

Goodridge RD, Dalgarno KW, Wood DJ. Indirect selective laser sintering of an apatite-mullite glass-ceramic for potential use in bone replacement applications. PhD thesis, University of Leeds, UK; 2005

Roodridgee RD, Wood DJ, Ohtsuki C, Dalgarno KW. Biological evaluation of an apatite-mullite glass-ceramic produced via selective laser sintering. Acta Biomater. 2006;3:221–31.

Fu Q, Rahaman MN, Day DE. Accelerated conversion of silicate bioactive glass (13–93) to hydroxyapatite in aqueous phosphate solution containing polyanions. J Am Ceram Soc. 2009;92:2870–6.

Brown RF, Day DE, Day TE, Jung S, Rahaman MN, Fu Q. Growth and differentiation of osteoblastic cells on 13–93 bioactive glass fibers and scaffolds. Acta Biomater. 2008;4:387–96.

Fu Q, Rahaman MN, Bal BS, Huang W, Day DE. Preparation and bioactive characteristics of a porous 13–93 glass, and fabrication into the articulating surface of a proximal tibia. J Biomed Mater Res Part A. 2007;82A:222–9.

Pirhonen E, Moimas L, Haapanen J. Porous bioactive 3-D glass fiber scaffolds for tissue engineering applications manufactured by sintering technique. Key Eng Mater. 2003;240–242:237–40.

Acknowledgments

The authors acknowledge the financial support for this research by the Center for Bone Tissue Repair and Regeneration at Missouri University of Science and Technology. The bioactive glass (13–93) used in this work was kindly provided by Mo-Sci Corp., Rolla, Missouri.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Doiphode, N.D., Huang, T., Leu, M.C. et al. Freeze extrusion fabrication of 13–93 bioactive glass scaffolds for bone repair. J Mater Sci: Mater Med 22, 515–523 (2011). https://doi.org/10.1007/s10856-011-4236-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4236-4