Abstract

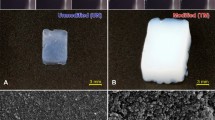

Light and X-ray scattering are used to examine the structure of two commercial precipitated silicas (Zeosil 1165 and Ultrasil 7005) and one developmental precipitated silica, Dimosil 288. All three products have a four-level hierarchical structure consisting of primary particles, aggregates, hard agglomerates and soft agglomerates, with Dimosil 288 showing the clearest evidence of the four structural levels. The impact of sonication and drying protocol was explored by light scattering for Dimosil 288. With the exception of the large-scale soft agglomerates, all the structural levels are robust under sonication of aqueous suspensions. Sonication breaks down soft agglomerates leaving hard structures approximately 11 μm in radius-of-gyration. Drying plays a critical role in hardening the soft agglomerates. If the product is never dried, sonication reduces the agglomerate size to 3.5 μm, which is identified as the size of the hard agglomerate. Although agglomerates larger than 3.5 μm are present in the never-dried product, they are friable. Large-scale agglomerates are marginally more robust when dried at 150 °C compared to room temperature drying. Given the similarity of mechanical properties of rubbers filled with these silicas, it appears that the four-level structure with friable large-scale soft agglomerates is a characteristic of highly dispersing silica products.

Similar content being viewed by others

References

D.W. Schaefer, R.S. Justice, Macromolecules 40(24), 8501 (2007)

D.W. Schaefer, C. Suryawanshi, P. Pakdel, J. Ilavsky, P.R. Jemian, Phys. A Stat. Mech. Appl. 314(1–4), 686 (2002)

D.J. Kohls, G. Beaucage, Curr. Opin. Solid State Mater. Sci. 6(3), 183 (2002)

T. Witten, M. Rubinstein, and R. H. Colby, J. Phys II (France) 3, 367 (1993)

M. Kluppel, Adv. Polym. Sci. 164, 1 (2003)

G. Beaucage, S. Rane, D.W. Schaefer, G. Long, D. Fischer, J. Polym. Sci. Part B Polym. Phys. 37(11), 1105 (1999)

D.J. Kohls, D.W. Schaefer, R. Kosso, E. Feinblum, in Current topics in elastomers research, ed. by A.K. Bhowmick (CRC Press, Boca Raton, 2008), p. 505

D.W. Schaefer, C.Y. Chen, Rubber Chem. Technol. 75(5), 773 (2002)

M.J. Wang, Rubber Chem. Technol. 71(3), 520 (1998)

G. Heinrich, T.A. Vilgis, Macromol. Symp. 93, 253 (1995)

B.T.N. Vu, J.E. Mark, D.W. Schaefer, Compos. Interfaces 10(4–5), 451 (2003)

P.A. Brühwiler, M. Barbezatt, A. Necola, D.J. Kohls, O. Bunk, D.W. Schaefer, P. Pötschke, J. Mater. Res. 25(6), 1118 (2010)

J. Zhao, D.W. Schaefer, D. Shi, J. Lian, J. Brown, G. Beaucage, L. Wang, R.C. Ewing, J. Phys. Chem. B 109, 23351 (2005)

L. Li, B. Li, M.A. Hood, C.Y. Li, Polymer 50(4), 953 (2009)

Y. Xie, D. Kohls, I. Noda, D.W. Schaefer, Y.A. Akpalu, Polymer 50(19), 4656 (2009)

D. W. Schaefer, D. J. Kohls, E. Feinblum, R. Kosso, and A. Vorobiev, Rubber and Plastics News (April 30), 16 (2007)

D.W. Schaefer, J. Zhao, H. Dowty, M. Alexander, E.B. Orler, Soft Matter 4(10), 2071 (2008)

A. Godara, L. Mezzo, F. Luizi, A. Warrier, S.V. Lomov, A.W. van Vuure, L. Gorbatikh, P. Moldenaers, I. Verpoest, Carbon 47(12), 2914 (2009)

E. Feinblum, U.S. Patent No. 5,302,364 (1992)

Y. Kolodny, Y. Nathan, E. Sass, J. Sediment. Petrol. 35(2), 454 (1965)

I. Tsyganova, Chemical Week (Sept. 27), 20 (2006)

D. J. Kohls, D. W. Schaefer, R. Kosso, and I. Tsyganova, Rubber Asia 21 (May–June), 73 (2007)

D.W. Schaefer, T. Rieker, M. Agamalian, J.S. Lin, D. Fischer, S. Sukumaran, C.Y. Chen, G. Beaucage, C. Herd, J. Ivie, J. Appl. Crystallogr. 33(1), 587 (2000)

D.W. Schaefer, M.M. Agamalian, Curr. Opin. Solid State Mater. Sci. 8(1), 39 (2004)

J. Ilavsky, P.R. Jemian, J. Appl. Crystallogr. 42(2), 347 (2009)

G. Beaucage, T.A. Ulibarri, E. Black, D.W. Schaefer, in Hybrid-organic inorganic composites, vol. 585, ed. by J.E. Mark, C.Y.-C. Lee, P.A. Bianconi (American Chemical Society, Washington, DC, 1995), p. 97

G. Beaucage, D.W. Schaefer, J. Non-Cryst. Solids 172, 797 (1994)

D.W. Schaefer, MRS Bull. 13(2), 22 (1988)

D.J. Kohls, D.W. Schaefer, R. Kosso, I. Tsyganova, Rubber World 236(1), 19 (2007)

Acknowledgments

Prof. James Mark sparked the interest of many researchers in nanocomposites long before they were called nanomaterials. Dale Schaefer’s introduction to this field resulted from Professor Mark’s Sabbatical visits to Sandia National Laboratories in the 1980 s. This research was partially supported by Dimona Silica Industries, LLC. We thank Andrey Vorobiev, Iryna Frenkel and Raisa Kosso for useful discussions. Dimosil 288 was synthesized at David Ben Gurion University of the Negev by Lev Shapiro, Vita Gudimenko and Yevgeny Gleizer. We thank Jan Ilavsky for assistance in collection of the USAXS data. The USAXS facility at the Advanced Photon Source is supported by the U. S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schaefer, D.W., Kohls, D. & Feinblum, E. Morphology of Highly Dispersing Precipitated Silica: Impact of Drying and Sonication. J Inorg Organomet Polym 22, 617–623 (2012). https://doi.org/10.1007/s10904-011-9643-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-011-9643-y