Abstract

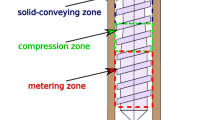

Non-homogeneous velocity distribution of the flow in the channel of a single-screw extruder is taken into account by a new model developed on the basis of the Markov chains. This model allows calculating the Residence Time Distribution (RTD) as well as the influence of the operating conditions on the process at any velocity distribution in the channel. It has been used to represent experimental results on mass flow rate and RTD previously obtained by extrusion of an acrylic polymer, Eudragit E100, at different temperatures and screw rotation speeds. The diffusion coefficient is the only adjusting parameter of the model. It was shown that it does not depend on the screw rotation speed and a correlation between this diffusion coefficient and the barrel temperature was found. The model provides global understanding of the transport kinetics of the flowing material through the extruder according to its behaviour and better describes the progress of the polymer flow all along the barrel from the hopper to the die.

Similar content being viewed by others

Abbreviations

- a :

-

Coefficient of the homographic equation (m/s)

- b :

-

Coefficient of the homographic equation (m2/s)

- B :

-

Distance between flanks (m)

- d :

-

Diameter of the screw (m)

- d z :

-

Transition probability along the axis z (–)

- d y :

-

Transition probability along the axis y (–)

- D :

-

Diffusion coefficient (m 2/s)

- D b :

-

Internal diameter of the barrel (m)

- e :

-

Width of the screw flank (m)

- E(i):

-

Calculated residence time distribution (–)

- E exp(t):

-

Experimental residence time distribution (–)

- g :

-

Coefficient of the homographic equation (m)

- g z :

-

The down channel pressure gradient (Pa/m)

- H :

-

Cross channel depth (m)

- j :

-

The transition number (–)

- L :

-

Length of the screw shaft (m)

- L f :

-

Length of the die (m)

- L s :

-

Length of the channel (m)

- L t :

-

Total path length (m)

- m :

-

Row number (–)

- M :

-

Mass of material in the extruder (kg)

- n :

-

Column number (–)

- P :

-

Matrix of transition probabilities (–)

- P ik :

-

Matrix of transition probabilities from kth to ith columns

- Q :

-

Mass flow rate (kg/s)

- r :

-

Throttle ratio (–)

- S :

-

State vector (–)

- t :

-

Time at which the calculated results are obtained (s)

- T :

-

Temperature of the barrel (°C)

- v :

-

Transition probability describing convection (–)

- V z :

-

Average velocity along the axis z (m/s)

- V ex :

-

Free volume of the extruder (m 3)

- W :

-

Channel width (m)

- Z :

-

Zero matrix (–)

- Δt :

-

Time interval (s)

- Δt exp :

-

Experimental time of sampling (s)

- Δy :

-

Height of a cell (m)

- Δz :

-

Length of a cell (m)

- ρ :

-

Average density of the material (kg/s)

- μ :

-

Viscosity (Pa s)

References

Rauwendaal C.: Polymer Extrusion, 4th edn. Hanser Publishers, München (2001)

Sauceau M., Fages J., Common A., Nikitine C., Rodier E.: Prog. Polym. Sci. 36, 749 (2011)

Lee S.-T.: Foam Extrusion. Principles and Practice. CRC press, Boca Raton (2000)

Sauceau M., Nikitine C., Rodier E., Fages J.: Supercrit. Fluids 43, 367 (2007)

Nikitine C., Rodier E., Sauceau M., Letourneau J.-J., Fages J.: J. Appl. Polym. Sci. 115, 981 (2010)

Yeh A.-I., Jaw Y.-M.: J. Food Eng. 35, 211 (1998)

Singh B., Rizvi S.H.: J. Food Process Eng. 21, 91 (1998)

Kazarian S.C.: Polym. Sci. 42, 78 (2000)

Tamir A.: Applications of Markov chains in Chemical Engineering. Elsevier Science Publisher, Amsterdam (1998)

Berthiaux H., Mizonov V.: Can. J. Chem. Eng. 6, 143 (2004)

B. Vergnes, S. Puissant, in Techniques de l’Ingénieur, traité Plastiques et Composites AM 3 650, pp. 1–16 (2002)

Nikitine C., Rodier E., Sauceau M., Fages J.: Chem. Eng. Res. Des. 87, 809 (2009)

Mizonov V., Berthiaux H., Arlabosse P., Djerroud D.: Granul. Matter 10, 335 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ponomarev, D., Rodier, E., Sauceau, M. et al. Modelling non-homogeneous flow and residence time distribution in a single-screw extruder by means of Markov chains. J Math Chem 50, 2141–2154 (2012). https://doi.org/10.1007/s10910-012-0022-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10910-012-0022-x