Abstract

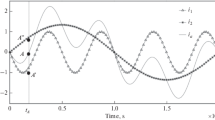

The nondestructive method to detect subsurface defects is limited because conventional eddy current are concentrated near to the surfaces adjacent to the excitation coil. The PEC technique enables detection of cracks buried deeper under the surface with relatively small current density. In the present study, an attempt has been made to investigate detection of subsurface cracks using a specially designed double-D differential probe. The tested sample is a SS304 with a thickness of 5 mm; small EDM notches were machined in the test sample at different depths from the surface to simulate the sub surface cracks in a pipe. The designed PEC probe has two excitation coils and two detecting Hall-sensors. The difference between two sensors is the resultant PEC signal. The cracks under the surface were detected using peak amplitude of the detected pulse; in addition, for a clear understanding of the crack depth, the Fourier transform is applied. In time domain, the peak amplitude of the detected pulse is decreased, and in the frequency domain, the magnitude of the lower frequency component has been increased with an increase in the crack depth. The experimental results have indicated that the proposed differential probe has the potential to detect the sub surface cracks in a stainless steel structure.

Similar content being viewed by others

References

Udpa, L., Udpa, S.S.: Neural networks for the classification of non-destructive evaluation signals. IEE Proc., F, Radar Signal Process. 138(1), 201–205 (1991)

Blitz, J.: Electrical and Magnetic Methods of Nondestructive Testing, p. 163. Chapman & Hall, London (1997)

He, Y., Luo, F., Pan, M.: Defect characterisation based on pulsed eddy current imaging technique. Sens. Actuators A, Phys. 164, 1–7 (2010)

Moulder, J.C., Bieber, J.A., Ward, W.W. III, Rose, J.H.: Scanned pulsed eddy current instrument for non-destructive inspection of aging aircraft. SPIE J. 2945, 2–13 (1996)

Kriezis, E.E., Tsiboukis, T.D., Panas, S.M., Tegopoulos, J.A.: Eddy currents: theory and applications. Proc. IEEE 80(10), 1559–1589 (1992)

Rao, B.P.C., Raj, B., Jayakumar, T., Kalyanasundaram, P.: An artificial neural network for eddy current testing of austenitic stainless steel welds. NDT Int. 35, 393–398 (2002)

Tian, G.Y., Zhao, Z.X., Baines, R.W.: The research of inhomogeneity in eddy current sensors. Sens. Actuators A Phys. 69, 148–151 (1998)

Hu, X., Luo, F.: Influence of different excitation parameters upon PEC testing for deep layered defect detection with rectangular sensor, computer. In: Int. Conf. on Mechatronics Controll and Electronic Engineering (CMCE), vol. 3, pp. 579–582 (2010)

Abdin, I.Z., Mandache, C., Tian, G.Y., Morozov, M.: Pulsed eddy current testing with variable duty cycle on rivet joints. NDT Int. 42, 599–605 (2009)

Libby, H.L.: Introduction to Electromagnetic Non-Destructive Test Methods p. 157. Wiley, New York (1971)

Waidelich, D.L.: Pulsed Eddy Current testing of steel sheets, eddy current characterization of materials and structures. ASTM Spec. Tech. Publ. 722, 367 (1981)

He, Y., Pan, M., Luo, F., Tian, G.: Pulsed Eddy Current imaging and frequency spectrum analysis for hidden defect nondestructive testing and evaluation. NDT Int. 44, 344–352 (2011)

Yang, H.C., Tai, C.C.: Pulsed Eddy Current measurement of a conducting coating on a magnetic metal plate. Meas. Sci. Technol. 13, 1259–1265 (2002)

Tian, G.Y., Sophian, A., Taylor, D., Rudlin, J.: Multiple sensors on pulsed eddy current detection for 3-D subsurface crack assessment. IEEE Sens. J. 5, 90–96 (2005)

Plotnikov, Y.A., Bantz, W.J.: Subsurface defect detection in metals with pulsed eddy current. Rev. Quant. Nondestruct Eval. 24, 447–454 (2005)

Angani, C.S., Pak, D.G., Kim, C.G., Leela, P., Kollu, P., Cheong, Y.M.: The pulsed eddy current differential probe to detect a thickness variation in an insulated stainless steel. J. Nondestruct. Eval. 29, 248–252 (2010)

Youhua, W., Junhua, W., Jiangui, L., Haohua, L.: Computational technologies in electrical and electronics engineering. In: Proc. of Int. Conf. on CTEEE, Novosibirsk, Russia, region 8, Sibircon, vol. 238 (2008)

Smith, R.A., Hugo, G.R.: Deep corrosion and crack detection in aging aircraft using transient eddy current NDE. Rev. Prog. Quant. Nondestruct. Eval. 6A, 1401–1408 (1999)

Acknowledgements

This work was developed by the research project on the development of prognostic diagnostic technique, as a part of nuclear R&D program supported by the ministry of education science and technology (MEST), Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, DG., Angani, C.S., Rao, B.P.C. et al. Detection of the Subsurface Cracks in a Stainless Steel Plate Using Pulsed Eddy Current. J Nondestruct Eval 32, 350–353 (2013). https://doi.org/10.1007/s10921-013-0188-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-013-0188-6