Abstract

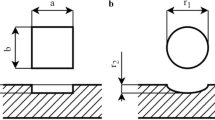

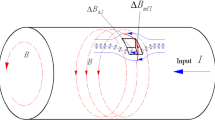

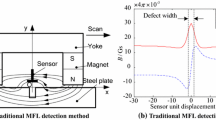

In magnetic flux leakage (MFL) testing technology, the MFL signals are thought to result from all defects and are used in their evaluation. The tested defects include two types of defects, concave and bump-shaped features, and recently described mechanisms in the MFL method indicate that the former defects produce positive MFL because of magnetic refraction and the latter ones produce negative magnetic fields because of self-magnetization regulation; consequently, these defects result in raised test signal waves and sunken test signal waves, respectively. Thereby, a new methodology for accurately identifying the defect type based on the mapping relation between the signal features and defect types is proposed. Both simulations and experiments with three representative defects (i.e., notch, protrusion and combination) were conducted to confirm their identification using this new methodology. Combined with MFL standards such as American Society for Testing and Materials (ASTM) E570-09 (Standard Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products, 2009) and British Standards (BS) EN 10246-4 (Non-destructive Testing of Steel Tubes—Part 4: Automatic Full Peripheral Magnetic Transducer/Flux Leakage Testing of Seamless Ferromagnetic Steel Tubes for the Detection of Transverse Imperfections, 2007), suggestions for standard specimens with reference defects that consist of both types of defects are provided.

Similar content being viewed by others

References

Spierer, E., Harbor, B.: Apparatus and process for flux leakage testing using transverse and vectored magnetization, US Patent 4477776, 1984

Förster, F.: New findings in the field of nondestructive magnetic leakage field inspection. NDT Int. 19(1), 3–13 (1986)

Hwang, J., Lord, W.: Finite element modeling of magnetic field/defect interactions. ASTM J. Test. Eval. 3(1), 21–25 (1975)

Edwards, C., Palmer, S.: The magnetic leakage field of surface breaking cracks. J. Phys. D Appl. Phys. 19, 657–673 (1986)

Atherton, D.L., Daly, M.G.: Finite element calculation of magnetic flux leakage detector signals. NDT Int. 20, 235–238 (1987)

Sun, Y.H., Kang, Y.H.: High-speed magnetic flux leakage technique and apparatus based on orthogonal magnetization for steel pipe. Mater. Eval. 68(4), 452–458 (2010)

Eickemeyer, R.: Magnetic gage for testing the magnetic conductivity of metals, US Patent 413338, 1889

Burrows, C.W.: Method of and apparatus for testing magnetizable objects by magnetic leakage, US Patent 1322405, 1919

Dutta, S., Ghorbel, F., Stanley, R.: Dipole modeling of magnetic flux leakage. IEEE Trans. Magn. 45(4), 1959–1965 (2009)

Li, Y., Wilson, J., Tian, G.Y.: Experiment and simulation study of 3D magnetic field sensing for magnetic flux leakage defect characterization. NDT Int. 40(2), 179–184 (2007)

Tsukada, K., Yoshioka, M., Kawasaki, Y., Kiwa, T.: Detection of back-side pit on a ferrous plate by magnetic flux leakage method with analyzing magnetic field vector. NDT E Int. 43, 323–328 (2003)

Katragadda, G., Si, J.T., Lord, W., Sun, Y.S., Udpa, S., Udpa, L.: A comparative study of 3D and axisymmetric magnetizer assemblies used in magnetic flux leakage inspection of pipelines. IEEE Trans. Magn. 32(3), 1573–1576 (1996)

Le, M., Lee, J., Jun, J., Kim, J., Moh, S., Shin, K.: Hall sensor array based validation of estimation of crack size in metals using magnetic dipole models. NDT E Int. 53, 18–25 (2013)

Mukhopadhyay, S., Srivastava, G.P.: Characterisation of metal loss defects from magnetic flux leakage signals with discrete wavelet transform. NDT E Int. 33, 57–65 (2000)

Katoh, M., Nishio, K., Yamaguchi, T.: The influence of modeled B-H curve on the density of the magnetic leakage flux due to a flaw using yoke-magnetization. NDT E Int. 37(8), 603–609 (2004)

Dutta, S.M., Ghorbel, F.H., Stanley, R.K.: Simulation and analysis of 3-D magnetic flux leakage. IEEE Trans. Magn. 45(4), 1966–1972 (2009)

Krause, T.W., Donaldson, R.M., Barnes, R., Atherton, D.L.: Variation of the stress dependent magnetic flux leakage signal with defect depth and flux density. NDT E Int. 29(2), 79–86 (1996)

Li, X.M., Ding, H.S., Bai, S.W.: Research on the stress-magnetism effect of ferromagnetic materials based on three-dimensional magnetic flux leakage testing. NDT E Int. 62, 50–54 (2014)

Mandayam, S., Udpa, L., Upda, S.S., Lord, W.: Invariance transformations for magnetic flux leakage signals. IEEE Trans. Magn. 32(3), 1577–1580 (1996)

Kopp, G., Willems, H.: Sizing limits of metal loss anomalies using tri-axial MFL measurements: a model study. NDT E Int. 55, 75–81 (2013)

Altschuler, E., Pignotti, A.: Nonlinear model of flaw detection in steel pipes by magnetic flux leakage. NDT E Int. 28(1), 35–40 (1995)

Goktepe, M.: Non-destructive crack detection by capturing local flux leakage field. Sens. Actuators A 91(1), 70–72 (2001)

Zhang, Y., Ye, Z.F., Wang, C.: A fast method for rectangular crack sizes reconstruction in magnetic flux leakage testing. NDT E Int. 42, 369–375 (2009)

Saha, S., Mukhopadhyay, S., Mahapatra, U., Bhattacharya, S., Srivastava, G.P.: Empirical structure for characterizing metal loss defects from radial magnetic flux leakage signal. NDT E Int. 43, 507–512 (2010)

Le, M., Lee, J., Jun, J., Kim, J.: Estimation of sizes of cracks on pipes in nuclear power plants using dipole moment and finite element methods. NDT E Int. 58, 56–63 (2013)

Uetake, I., Saito, T.: Magnetic flux leakage by adjacent parallel surface slots. NDT E Int. 30(6), 371–376 (1997)

Minkov, D., Shoji, T.: Method for sizing of 3-D surface breaking flaws by leakage flux. NDT E Int. 31(5), 317–324 (1998)

Coughlin, C.R., Clapham, L., Atherton, D.L.: Effects of stress on MFL responses from elongated corrosion pits in pipeline steel. NDT E Int. 33, 181–188 (2000)

Amineh, R.K., Koziel, S., Nikolova, N.K., Bandler, J.W., Reilly, J.P.: A space mapping methodology for defect characterization from magnetic flux leakage measurements. IEEE Trans. Magn. 44(8), 2058–2065 (2008)

Ravan, M., Amineh, R.K., Koziel, R.K., et al.: Sizing of 3-D arbitrary defects using magnetic flux leakage measurements. IEEE Trans. Magn. 46(4), 1024–1033 (2010)

Mukherjee, D., Saha, S., Mukhopadphay, S.: Inverse mapping of magnetic flux leakage signal for defect characterization. NDT E Int. 54, 198–208 (2013)

Chen, Z., Preda, G., Mihalache, O., Miya, K.: Reconstruction of crack shapes from the MFLT signals by using a rapid forward solver and an optimization approach. IEEE Trans. Magn. 38(2), 1025–1028 (2002)

Jomdecha, C., Prateepsen, A.: Design of modified electromagnetic main-flux for steel wire pipe inspection. NDT E Int. 42, 77–83 (2009)

Gloria, N.B.S., Areiza, M.C.L., Miranda, I.V.J., Rebello, J.M.A.: Development of a magnetic sensor for detection and sizing of internal pipeline corrosion defects. NDT E Int. 42, 669–677 (2009)

Zhang, Y., Ye, Z.F., Xu, X.: An adaptive method for channel equalization in MFL inspection. NDT E Int. 40, 127–139 (2007)

Joshi, A., Udpa, L., Udpa, S., Tamburrino, A.: Adaptive wavelets for characterizing magnetic flux leakage signals from pipeline inspection. IEEE Trans. Magn. 42(10), 3168–3170 (2006)

ASTM E570-09: Standard Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products, June 2009

BS EN 10246-4: Non-destructive Testing of Steel Tubes—Part 4: Automatic Full Peripheral Magnetic Transducer/Flux Leakage Testing of Seamless Ferromagnetic Steel Tubes for the Detection of Transverse Imperfections, May 2007

Sun, Y.H., Kang, Y.H.: Magnetic compression effect in present MFL testing sensor. Sens. Actuators A. 160, 54–59 (2010)

Sun, Y.H., Kang, Y.H.: A new MFL principle and method based on near-zero background magnetic field. NDT E Int. 43, 348–353 (2010)

Stratton, J.A.: Electromagnetic Theory, IEEE Antennas and Propagation Society Press. Wiley, Hoboken (2007)

Acknowledgments

This paper was financially supported by the National Natural Science Foundation of China (NNSFC) [51475194], the National Key Basic Research Program of China [2014CB046706] and the National Natural Science Foundation of China (NNSFC) [51275193].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Feng, B., Liu, S. et al. A Methodology for Identifying Defects in the Magnetic Flux Leakage Method and Suggestions for Standard Specimens. J Nondestruct Eval 34, 20 (2015). https://doi.org/10.1007/s10921-015-0293-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-015-0293-9