Abstract

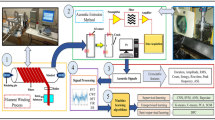

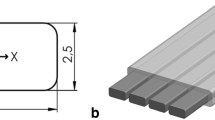

Infrared thermography (IT) is a safe non-destructive evaluation technique that has a fast inspection rate and is generally contactless. It is used for diagnostics and monitoring in several fields including composite materials. In this paper carbon fiber-reinforced polymer plates submitted to tensile testing are inspected using IT. More specifically, carbon/polyether ether ketone panels made of random-oriented strands by compression moulding are submitted to tensile testing and then inspected using three different IT active approaches. The first two approaches use optical sources however with different scanning modes. The first active approach tested is a static surface scanning inspection in reflection mode. The second one is a dynamic line scanning technique where the energy source and camera are in movement with regards to the test sample. The last active IT approach tested uses a mechanical source (ultrasound excitation) to transfer heat to the sample being tested. This last approach is commonly called vibrothermography. Results obtained were then compared to results obtained by micro computed tomography inspection and microscopy. Results revealed voids associated with resin-rich regions as well as cracks.

Similar content being viewed by others

References

Balageas, D.L.: Defense and illustration of time-resolved pulsed thermography for nde. Quant. InfraRed Thermogr. J. 9(1), 3–32 (2012). doi:10.1080/17686733.2012.676902

Gruss, C., Balageas, D.: Theoretical and experimental applications of the flying spot camera. Proc. QIRT 92, 19–24 (1992)

Hale, J.: Boeing 787, from the ground up. Aero Mag. 24(4), 16–23 (2006)

Ibarra-Castanedo, C., Maldague, X.: Infrared thermography. In: Czichos, H. (ed.) Handbook of Technical Diagnostics, pp. 175–220. Springer, Berlin (2013)

Ibarra-Castanedo, C., Bendada, A.H., Maldague, X.: Image and signal processing techniques in pulsed thermography. GESTS Int. Trans. Comput. Sci. Eng. 22(1), 89–100 (2005)

Ibarra-Castanedo, C., Tarpani, J.R., Maldague, X.: Nondestructive testing with thermography. Eur. J. Phys. 34(6), S91 (2013). doi:10.1088/0143-0807/34/6/S91

Lopez, F., Ibarra-Castanedo, C., Nicolau, V.P., Maldague, X.: Optimization of pulsed thermography inspection by partial least-squares regression. NDT & E Int. 66, 128–138 (2014)

Maldague, X.: Theory and Practice of Infrared Technology for Nondestructive Testing, 1st edn. Wiley, New York (2001)

Mian, A., Newaz, G., Han, X., Mahmood, T., Saha, C.: Response of sub-surface fatigue damage under sonic load a computational study. Compos. Sci. Technol. 64(9), 1115–1122 (2004)

Oswald-Tranta, B., Shepard, S.: Comparison of pulse phase and thermographic signal reconstruction processing methods. In: Proceedings SPIE, Thermosense XXXV, vol. 8705, pp. 87. 050S1–9 (2013)

Rajic, N.: Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 58(4), 521–528 (2002)

Renshaw, J., Chen, J.C., Holland, S.D., Thompson, R.B.: The sources of heat generation in vibrothermography. NDT & E Int. 44(8), 736–739 (2011)

Rothenfusser, M.J., Homma, C.: Acoustic thermography: vibrational modes of cracks and the mechanism of heat generation. AIP Conf. Proc. 760, 624–631 (2005)

Selezneva, M., Kouwonou, K., Lessard, L., Hubert, P.: Mechanical properties of randomly oriented strands thermoplastic composites. In: S.V. Hoa, P. Hubert (eds.) Proceedings 19th International Conference on Composite Materials (Montreal, Canada, July 2013), vol. 1, pp. 480–488. (2013)

Shepard, S.M.: Advances in pulsed thermography. In: Proceedings SPIE, Thermosense: thermal Infrared Applications XXVIII, vol. 4360, pp. 511–515. (2001)

Shepard, S., Ahmed, T., Lhota, J.R.: Experimental considerations in vibrothermography. In: Proceedings SPIE, Thermosense XXVID, vol. 5405, pp. 332–335. (2004)

Vavilov, V.P., Burleigh, D.D.: Review of pulsed thermal NDT: physical principles, theory and data processing. NDT & E Int. 73, 28–52 (2015)

Woolard, D.F., Cramer, K.E.: The thermal photocopier: a new concept for thermal ndt. In: Proceedings SPIE, Thermosense XXVI, vol. 5405, pp. 366–373. (2004)

Woolard, D.F., Cramer, K.E.: Line scan versus flash thermography: comparative study on reinforced carbon-carbon. In: Proceedings SPIE, Thermosense XXVII, vol. 2782, pp. 315–323. (2005)

Acknowledgments

The authors would like to thank PhD student Marina Selezneva from the Structures and Composites Materials Laboratory of McGill University and NRC-Boucherville who manufactured the parts inspected in this work and performed microscopy and \(\mu \)CT inspections. The authors would like to gratefully acknowledge support provided by the Canada Research Chair in Multipolar Infrared Vision (MiViM) and the industrial partners: Bell Helicopter Textron Canada Limited, Bombardier Inc., Pratt and Whitney Canada Corp., Avior Integrated Products Inc., Delastek Inc. and Hutchinson Inc. Canada. The authors would also like to acknowledge the support of the following agencies: CNPq, National Council for Scientific and Technological Development - Brazil; NSERC, Natural Sciences and Engineering Research Council of Canada; FQRNT, Quebec Fund for Research on Nature and Technology and CRIAQ, Consortium for Research and Innovation in Aerospace in Quebec.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernandes, H., Ibarra-Castanedo, C., Zhang, H. et al. Thermographic Non-destructive Evaluation of Carbon Fiber-Reinforced Polymer Plates After Tensile Testing. J Nondestruct Eval 34, 35 (2015). https://doi.org/10.1007/s10921-015-0303-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-015-0303-y