Abstract

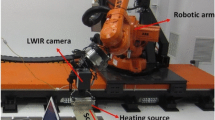

The emergence of composite materials has started a revolution in the aerospace industry. When using composite materials, it is possible to design larger and lighter components. However, due to their anisotropy, composite materials are usually difficult to inspect and detecting internal defects is a challenge. Line scan thermography (LST) is a dynamic thermography technique, which is used to inspect large components of metallic surfaces and composites, commonly used in the aerospace industry. In this paper, the robotized LST technique has been investigated on a large composite component which contains different types of internal defects located at a variety of depths. For theoretical analysis, the LST inspection was simulated using a mathematical formulation based on the 3D heat conduction equation in the transient regime in order to determine the optimum parameters. The solution of the model was performed using the finite element method. The LST parameters were adjusted to detect the deepest defects in the specimen. In order to validate the numerical results with experimental data, a robotized system in which the infrared camera and the heating source move in tandem, has been employed. From the experimental tests, it was noted that there are three sources of noise (non-uniform heating, unsynchronized frame rate with scanning speed and robot arm vibration) which affect the performance of the test. In this work, image processing techniques that were initially developed to be applied on pulse thermography have been successfully implemented. Finally, the performance of each technique was evaluated using the probability of detection approach.

Similar content being viewed by others

References

Bonavolonta, C., Valentino, M., Peluso, G., Barone, A.: Nondestructive evaluation of advanced composite materials for aerospace application using hts squids. IEEE Trans. Appl. Supercond. 17(2), 772–775 (2007). doi:10.1109/TASC.2007.897193

Hull, D., Clyne, T.: An Introduction to Composite Materials. Cambridge University Press, New York (1996)

Matthews, D.F., Rawlings, R.D.: Composite Materials: Engineering and Science. Elsevier (1999)

Soutis, C.: Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 41(2), 143–151 (2005)

Lopez, F., Ibarra-Castanedo, C., Maldague, X., Nicolau, V.: Pulsed thermography signal processing techniques based on the 1d solution of the heat equation applied to the inspection of laminated composites. Mater. Eval. 72, 91–102 (2014)

Ibarra-Castanedo, C., Gonzalez, D., Klein, M., Pilla, M., Vallerand, S., Maldague, X.: Infrared image processing and data analysis. Infrared. Phys. Technol. 46(1), 75–83 (2004)

Ibarra-Castanedo, C., Genest, M., Servais, P., Maldague, X., Bendada, A.: Qualitative and quantitative assessment of aerospace structures by pulsed thermography. Nondestruct. Test. Eval. 22(2–3), 199–215 (2007)

Ibarra-Castanedo, C., Avdelidis, N.P., Grinzato, E.G., Bison, P.G., Marinetti, S., Plescanu, C.C., Bendada, A., Maldague, X.P.: Delamination detection and impact damage assessment of glare by active thermography. Int. J. Mater. Prod. Technol. 41(1–4), 5–16 (2011)

Dillenz, A., Zweschper, T., Busse, G.: Progress in ultrasound phase thermography. In: Aerospace/Defense Sensing, Simulation, and Controls. International Society for Optics and Photonics, pp. 574–579 (2001)

Favro, L., Han, X., Ouyang, Z., Sun, G., Sui, H., Thomas, R.: Infrared imaging of defects heated by a sonic pulse. Rev. Sci. Instrum. 71(6), 2418–2421 (2000)

McCann, D., Forde, M.: Review of ndt methods in the assessment of concrete and masonry structures. NDT & E Int. 34(2), 71–84 (2001)

Ibrahim, M.: Nondestructive evaluation of thick-section composites and sandwich structures: a review. Compos. A Appl. Sci. Manuf. 64, 36–48 (2014)

Gholizadeh, S.: A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 1, 50–57 (2016)

Ley, O., Godinez-Azcuaga, V.: Line scanning thermography and its application inspecting aerospace composites. In: 5th International Symposium on NDT in Aerospace, Singapore

Ibarra-Castanedo, C., Servais, P., Ziadi, A., Klein, M., Maldague, X.: RITA-Robotized Inspection by Thermography and Advanced processing for the inspection of aeronautical components. In: 12th International Conference on Quantitative InfraRed Thermography (2014)

Woolard, D.F., Cramer, K.E.: Line scan versus ash thermography: comparative study on reinforced carbon-carbon. In: Defense and Security, International Society for Optics and Photonics, pp. 315–323 (2005)

Aieta, N.V., Das, P.K., Perdue, A., Bender, G., Herring, A.M., Weber, A.Z., Ulsh, M.J.: Applying infrared thermography as a quality-control tool for the rapid detection of polymer-electrolyte-membrane-fuel-cell catalyst-layer-thickness variations. J. Power Sources 211, 4–11 (2012)

Kaltmann, D.: Quantitative line-scan thermographic evaluation of composite structures, Masters by Research, Aerospace, Mechanical and Manufacturing Engineering, RMIT University

Benitez, H., Ibarra-Castanedo, C., Bendada, A., Maldague, X., Loaiza, H., Caicedo, E.: Modified differential absolute contrast using thermal quadrupoles for the nondestructive testing of finite thickness specimens by infrared thermography. In: Electrical and Computer Engineering, 2006. CCECE’06. Canadian Conference on, IEEE, 2006, pp. 1039–1042

Ibarra-Castanedo, C., Benitez, H., Maldague, X., Bendada, A.: Review of thermal-contrast based signal processing techniques for the nondestructive testing and evaluation of materials by infrared thermography. In: Proceedings of the International Workshop on Imaging NDE (Kalpakkam, India, 25–28 April 2007), pp. 1–6 (2007)

Lopez, F., de Paulo Nicolau, V., Ibarra-Castanedo, C., Maldague, X.: Thermal numerical model and computational simulation of pulsed thermography inspection of carbon fiber reinforced composites. Int. J. Therm. Sci. 86, 325–340 (2014)

Oswald-Tranta, B., Sorger, M.: Scanning pulse phase thermography with line heating. Quant. InfraRed Thermogr. J. 9(2), 103–122 (2012)

Ibarra-Castanedo, C., Bendada, A., Maldague, X.: Thermographic image processing for NDT. In: IV Conferencia Panamericana de END, vol. 79. Citeseer (2007)

Vavilov, V., Nesteruk, D., Shirayev, V., Ivanov, A.: Some novel approaches to thermal tomography of CFRP composites. In: Proceedings of the 10th International Conference on Quantitative Infrared Thermography, FIE du CAO, pp. 433–440 (2010)

Vahid, P.H., Hesabi, S., Maldague, X.: The effect of pre-processing techniques in detecting defects of thermal images

Fariba, K., Saeed, S., Maldague, X.: Infrared thermography and NDT: 2050 horizon, QIRT

Lopez, F., Nicolau, V., Maldague, X., Ibarra-Castanedo, C.: Multivariate infrared signal processing by partial least-squares thermography. In: ISEM Conference (2013)

Lopez, F., Ibarra-Castanedo, C., Maldague, X., de Paulo Nicolau, V.: Analysis of signal processing techniques in pulsed thermography. In: SPIE Defense, Security, and Sensing, International Society for Optics and Photonics, 2013, pp. 87050W–87050W

Ibarra-Castanedo, C., Avdelidis, N.P., Grenier, M., Maldague, X., Bendada, A.: Active thermography signal processing techniques for defect detection and characterization on composite materials. In: SPIE Defense, Security, and Sensing, International Society for Optics and Photonics, 2010, pp. 76610O–76610O

Duan, Y.: Probability of detection analysis for infrared nondestructive testing and evaluation with applications including a comparison with ultrasonic testing, Ph.D. thesis, Universite Laval (2014)

Castanedo, C.I.: Quantitative subsurface defect evaluation by pulsed phase thermography: depth retrieval with the phase, Ph.D. thesis, Universite Laval (2005)

Rosipal, R., Kramer, N.: Overview and recent advances in partial least squares. In: Subspace, Latent Structure and Feature Selection. Springer, pp. 34–51 (2006)

Lopez, F., Ibarra-Castanedo, C., de Paulo Nicolau, V., Maldague, X.: Optimization of pulsed thermography inspection by partial least-squares regression. NDT & E Int. 66, 128–138 (2014)

Duan, Y., Servais, P., Genest, M., Ibarra-Castanedo, C., Maldague, X.P.: Thermopod: A reliability study on active infrared thermography for the inspection of composite materials. J. Mech. Sci. Technol. 26(7), 1985–1991 (2012)

Junyan, L., Yang, L., Fei, W., Yang, W.: Study on probability of detection (pod) determination using lock-in thermography for nondestructive inspection (ndi) of cfrp composite materials. Infrared Phys. Technol. 71, 448–456 (2015)

Wehling, P., LaBudde, R.A., Brunelle, S.L., Nelson, M.T.: Probability of detection (pod) as a statistical model for the validation of qualitative methods. J. AOAC Int. 94(1), 335–347 (2011)

Duan, Y., Huebner, S., Hassler, U., Osman, A., Ibarra-Castanedo, C., Maldague, X.P.: Quantitative evaluation of optical lock-in and pulsed thermography for aluminum foam material. Infrared Phys. Technol. 60, 275–280 (2013)

Georgiou, G.A.: Probability of detection (pod) curves: derivation, applications and limitations. Jacobi Consulting Limited Health and Safety Executive Research Report 454

Muller, C., Elaguine, M., Bellon, C., Ewert, U., Zscherpel, U., Scharmach, M., Redmer, B., Ryden, H., Ronneteg, U.: Pod (probability of detection) evaluation of NDT techniques for cu-canisters for risk assessment of nuclear waste encapsulation. In: Proceedings of the 9th European Conference on NDT, Berlin, German, Sept, 2006, pp. 25–29

Acknowledgements

The authors are thankful for the support of the following organizations which help to fund our research activities: Natural Science and Engineering Research Council of Canada, Canada Research Chair Secretariat, Ministre des Relations Internationales du Quebec and Quebec-Wallonia/Brussels Program, Visioimage Ltd., Centre.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khodayar, F., Lopez, F., Ibarra-Castanedo, C. et al. Optimization of the Inspection of Large Composite Materials Using Robotized Line Scan Thermography. J Nondestruct Eval 36, 32 (2017). https://doi.org/10.1007/s10921-017-0412-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-017-0412-x