Abstract

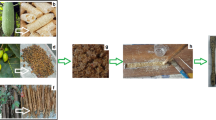

Untreated and treated jute fiber and nano-clay in various ratios were used to fabricate jute/nano-clay/epoxy hybrid composites through compression molding method. The dynamic mechanical and free vibration behaviours were evaluated by varying the concentration of NaOH (2.5%, 5% and 7.5%) and wt.% of nano-clay (1, 3, 5 and 7 wt.%). Experimental outcomes disclosed that the storage and loss modulus, damping factor and natural frequency are influenced by concentration of NaOH solution and nano-clay content. A positive shift (towards higher temperature) in glass transition temperature and enhanced natural frequency of the composites after NaOH treatment and nano-clay addition confirmed that superior interfacial bonding exists between the jute fibers and epoxy matrix. Finally, the composites incorporated with 5% treated fiber and 5 wt.% of nano-clay is suggested for low strength structural applications in construction and automobile industries.

Similar content being viewed by others

References

Senthilkumar K, Saba N, Chandrasekar M, Jawaid M, Rajini N, Alothman OY, Siengchin S (2019) Evaluation of mechanical and free vibration properties of the pineapple leaf fibre reinforced polyester composites. Constr Build Mater 195:423–431

Pappu A, Pickering KL, Thakur VK (2019) Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind Crops Prod 137:260–269

Alves C, Silva AJ, Reis LG, Freitas M, Rodrigues LB, Alves DE (2010) Ecodesign of automotive components making use of natural jute fiber composites. J Clean Prod 18(4):313–327

Abdellaoui H, Bensalah H, Raji M, Rodrigue D, Bouhfid R, El-Kacem QA (2017) Laminated epoxy biocomposites based on clay and jute fibers. J Bionic Eng 14(2):379–389

Ray D, Sarkar BK, Das S, Rana AK (2002) Dynamic mechanical and thermal analysis of vinylester-resin-matrix composites reinforced with untreated and alkali-treated jute fibres. Compos Sci Technol 62(7–8):911–917

Vinod A, Vijay R, Singaravelu DL (2018) Thermo-Mechanical characterization of calotropis gigantea stem powder-Filled jute fiber-Reinforced epoxy composites. J Nat Fibers 15(5):648–657

Rashed HMMA, Islam MA, Rizvi FB (2006) Effects of process parameters on tensile strength of jute fiber reinforced thermoplastic composites. J Nav Archit Mar Eng 3(1):1–6

Plackett D, Andersen TL, Pedersen WB, Nielsen L (2003) Biodegradable composites based on L-polylactide and jute fibres. Compos Sci Technol 63(9):1287–1296

Ramakrishnan S, Krishnamurthy K, Rajasekar R, Rajeshkumar G (2019) An experimental study on the effect of nano-clay addition on mechanical and water absorption behaviour of jute fibre reinforced epoxy composites. J Ind Text 49(5):597–620

Gopinath A, Kumar MS, Elayaperumal A (2014) Experimental investigations on mechanical properties of jute fiber reinforced composites with polyester and epoxy resin matrices. Procedia Eng 97:2052–2063

Rajeshkumar G (2020) Effect of sodium hydroxide treatment on dry sliding wear behavior of Phoenix sp. fiber reinforced polymer composites. J Ind Text. https://doi.org/10.1177/1528083720918948

Siakeng R, Jawaid M, Asim M, Saba N, Sanjay MR, Siengchin S, Fouad H (2020) Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. eXPRESS Polym Lett 14(8):717

Rajeshkumar G, Ramakrishnan S, Pugalenthi T, Ravikumar P (2020) Performance of surface modified pineapple leaf fiber and its applications. In: Jawaid M, Asim M, Md. Tahir P, Nasir M (eds) Pineapple leaf fibers. Springer, Singapore, pp 309–321

Asim M, Jawaid M, Abdan K, Ishak MR (2016) Effect of alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. J Bionic Eng 13(3):426–435

Saba N, Jawaid M, Alothman OY, Paridah MT (2016) A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr Build Mater 106:149–159

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos Sci Technol 63:283–293

Rajeshkumar G (2020) Characterization of surface modified phoenix sp. fibers for composite reinforcement. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1711284

Sathishkumar TP (2016) Dynamic mechanical analysis of snake grass fiber-reinforced polyester composites. Proc Inst Mech Eng Part L 230:160–174

Devi LU, Bhagawan SS, Thomas S (2011) Dynamic mechanical properties of pineapple leaf fiber polyester composites. Polym Compos 32(11):1741–1750

Singhal P, Tiwari SK (2014) Effect of various chemical treatments on the damping property of jute fibre reinforced composite. Int J Adv Mech Eng 4(4):413–424

Saha AK, Das S, Bhatta D, Mitra BC (1999) Study of jute fiber reinforced polyester composites by dynamic mechanical analysis. J Appl Polym Sci 71(9):1505–1513

Jabbar A, Militký J, Wiener J, Karahan M (2016) Static and dynamic mechanical properties of novel treated jute/green epoxy composites. Text Res J 86(9):960–974

Roy K, Debnath SC, Das A, Heinrich G, Potiyaraj P (2018) Exploring the synergistic effect of short jute fiber and nanoclay on the mechanical, dynamic mechanical and thermal properties of natural rubber composites. Polym Test 67:487–493

Hasan MH, Mollik MS, Rashid MM (2018) Effect of nanoclay on thermal behavior of jute reinforced composite. Int J Adv Manuf Technol 94(5–8):1863–1871

Rajesh M, Jeyaraj P, Rajini N (2016) Mechanical, dynamic mechanical and vibration behavior of nanoclay dispersed natural fiber hybrid intra-ply woven fabric composite. In: Jawaid M, Qaiss AK, Bouhfid R (eds) Nanoclay reinforced polymer composites. Springer, Singapore, pp 281–296

Fiore V, Scalici T, Vitale G, Valenza A (2014) Static and dynamic mechanical properties of Arundo Donax fillers-epoxy composites. Mater Des 57:456–464

Ameer MH, Shaker K, Ashraf M, Karahan M, Nawab Y, Ahmad S, Nasir MA (2017) Interdependence of moisture, mechanical properties, and hydrophobic treatment of jute fibre-reinforced composite materials. J Text Inst 108(10):1768–1776

Gheith MH, Aziz MA, Ghori W, Saba N, Asim M, Jawaid M, Alothman OY (2019) Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J Mater Res Technol 8(1):853–860

Negawo TA, Polat Y, Buyuknalcaci FN, Kilic A, Saba N, Jawaid M (2019) Mechanical, morphological, structural and dynamic mechanical properties of alkali treated ensete stem fibers reinforced unsaturated polyester composites. Compos Struct 207:589–597

Ouajai S, Shanks RA (2005) Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym Degrad Stab 89(2):327–335

Tajvidi M (2005) Static and dynamic mechanical properties of a kenaf fiber–wood flour/polypropylene hybrid composite. J Appl Polym Sci 98(2):665–672

Fiore V, Di Bella G, Valenza A (2015) The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos Part B: Eng 68:14–21

Asim M, Jawaid M, Paridah MT, Saba N, Nasir M, Shahroze RM (2019) Dynamic and thermo-mechanical properties of hybridized Kenaf/PALF reinforced phenolic composites. Polym Compos 40(10):3814–3822

Shanmugam D, Thiruchitrambalam M (2013) Static and dynamic mechanical properties of alkali treated unidirectional continuous palmyra palm leaf stalk fiber/jute fiber reinforced hybrid polyester composites. Mater Des 50:533–542

Rajesh M, Jeyaraj P, Rajini N (2016). In: Jawaid M, el Qaiss K, Bouhfid A (eds) Nanoclay reinforced polymer composites. Springer, Singapore, pp 281–296

Sim IN, Han SO (2013) Effect on modified nanoclay on dynamic mechanical and thermomechanical properties of natural fiber/polypropylene biocomposites. J Adhes Sci Technol 27(12):1313–1323

Biswal M, Mohanty S, Nayak SK (2011) Mechanical, thermal and dynamic- mechanical behavior of banana fiber reinforced polypropylene nanocomposites. Polym Compos 32(8):1190–1201

Han G, Lei Y, Wu Q, Kojima Y, Suzuki S (2008) Bamboo–fiber filled high density polyethylene composites: effect of coupling treatment and nanoclay. J Polym Environ 16(2):123–130

John B, Nair CR, Ninan KN (2010) Effect of nanoclay on the mechanical, dynamic mechanical and thermal properties of cyanate ester syntactic foams. Mater Sci Eng: A 527(21–22):5435–5443

Eng CC, Ibrahim NA, Zainuddin N, Ariffin H, Yunus WM, Wan Z, Then YY (2014) Enhancement of mechanical and dynamic mechanical properties of hydrophilic nanoclay reinforced polylactic acid/polycaprolactone/oil palm mesocarp fiber hybrid composites. Int J Polym Sci 2014:1–8

Sadhu S, Bhowmick AK (2005) Effect of nanoclay on the dynamic mechanical properties of styrene butadiene and acrylonitrile butadiene rubber vulcanizates. Rubber Chem Technol 78(2):321–335

Selvakumar K, Meenakshisundaram O (2018) Mechanical and dynamic mechanical analysis of jute and human hair-reinforced polymer composites. Polym Compos. https://doi.org/10.1002/pc.24818

Gupta MK, Srivastava RK (2016) Tribological and dynamic mechanical analysis of epoxy based hybrid sisal/jute composite. Indian J Eng Mater Sci 23:37–44

Gupta MK (2018) Thermal and dynamic mechanical analysis of hybrid jute/sisal fibre reinforced epoxy composite. J Mater: Des Appl 232(9):743–748

Gupta MK (2017) Effect of frequencies on dynamic mechanical properties of hybrid jute/sisal fibre reinforced epoxy composite. Adv Mater Process Technol 3(4):651–664

Chaudhary V, Bajpai PK, Maheshwari S (2018) An investigation on wear and dynamic mechanical behavior of jute/hemp/flax reinforced composites and its hybrids for tribological applications. Fiber Polym 19(2):403–415

Pawar MJ, Patnaik A, Nagar R (2017) Investigation on mechanical and thermo-mechanical properties of granite powder filled treated jute fiber reinforced epoxy composite. Polym Compos 38(4):736–748

Karaduman Y, Onal L (2012) Dynamic mechanical and thermal properties of enzyme-treated jute/polyester composites. J Compos Mater 47(19):2361–2370

Rajesh M, Pitchaimani J (2018) Dynamic mechanical and free vibration behavior of natural fiber braided fabric composite: comparison with conventional and knitted fabric composites. Polym Compos 39(7):2479–2489

Ni X, Dong A, Fan X, Wang Q, Yu Y, Cavaco-Paulo A (2015) Jute/polypropylene composites: effect of enzymatic modification on thermo-mechanical and dynamic mechanical properties. Fibers Polym 16(10):2276–2283

Rajesh M, Pitchaimani J, Rajini N (2016) Free vibration characteristics of banana/sisal natural fibers reinforced hybrid polymer composite beam. Procedia Eng 144:1055–1059

Rajeshkumar G, Hariharan V, Scalici T (2016) Effect of NaOH treatment on properties of Phoenix sp. fiber. J Nat Fibers 13(6):702–713

Senthilrajan S, Venkateshwaran N (2019) Ageing and its influence on vibration characteristics of jute/polyester composites. J Polym Environ 27(10):2144–2155

Arulmurugan S, Venkateshwaran N (2016) Vibration analysis of nanoclay filled natural fiber composites. Polym Polym Compos 24(7):507–516

Kumar GR, Hariharan V, Saravanakumar SS (2019) Enhancing the free vibration characteristics of epoxy polymers using sustainable Phoenix sp. fibers and nano-clay for machine tool applications. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1636740

Rajini N, Jappes JW, Rajakarunakaran S, Jeyaraj P (2012) Mechanical and free vibration properties of montmorillonite clay dispersed with naturally woven coconut sheath composite. J Reinf Plast Compos 31(20):1364–1376

Rajini N, Jappes JW, Rajakarunakaran S, Jeyaraj P (2013) Dynamic mechanical analysis and free vibration behavior in chemical modifications of coconut sheath/nano-clay reinforced hybrid polyester composite. J Compos Mater 47(24):3105–3121

Chandradass J, Kumar MR, Velmurugan R (2007) Effect of nanoclay addition on vibration properties of glass fibre reinforced vinyl ester composites. Mater Lett 61(22):4385–4388

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramakrishnan, S., Krishnamurthy, K., Rajeshkumar, G. et al. Dynamic Mechanical Properties and Free Vibration Characteristics of Surface Modified Jute Fiber/Nano-Clay Reinforced Epoxy Composites. J Polym Environ 29, 1076–1088 (2021). https://doi.org/10.1007/s10924-020-01945-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01945-y