Abstract

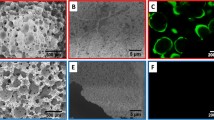

Porous implants having interconnecting channels allow ingrowth of host connective tissue. Complete implant vascularization reduces the risk of infection, extrusion, and other complications associated with nonintegrated implants. Attempts were made to develop 60% and 70% porous ultra high molecular weight polyethylene (UHMWPE) scaffolds and blocks using sodium chloride as channeling agent, which when dissolved in boiling water leaves behind the interconnecting channels. The average diameter of the pores of 60% and 70% porous scaffolds was found to be approx. 170 µm and 210 µm, respectively. Mechanical characterizations of the scaffolds indicated sufficient strength to be used for orbital implant fabracation. Surface roughness of the scaffolds indicated increase in surface roughness with the increase in porosity. The scaffolds developed were found to be hemocompatible with the human blood. Subsequently, the 70% porous scaffold was dip coated with a solution mixture of sodium carboxy methyl cellulose (SCMC)/polyvinyl alcohol (PVA)/hydroxyapatite (HA) which also showed hemocompatibility. Ciprofloxacin release pattern from the membrane was determined. Finally an orbital implant was fabricated from the 70% porous scaffold.

Similar content being viewed by others

References

W.T. Couldwell, T.C. Chen, M.H. Weiss, J. Neurosurg. 81, 483 (1994)

D.A. Cottrell, L.M. Wolford, J. Oral Maxillofac. Surg. 56, 935 (1998)

P.A.D. Rubin, J. Popham, S. Rumelt, H. Remulla, J.R. Bilyk, J. Holds, G. Mannor, M. Maus Patrinely, J. Ophthalmol., 105(5), 919 (1998)

M.L. Gonzalez-Rodriguez, J.I. Perez-Martinez, S. Merino, A. Fini, A.M. Rabasco. Drug Dev. IndPharm. May; 27(5), 439 (2001)

http://landau1.phys.virginia.edu/classes/241L/poise/poise.htm

H. L. Stein, P. E. Ticona, Ultra High Molecular Weight Polyethylene (UHMWPE), Guide to Engineering Plastic Families: Thermoplastic Resins, vol. 2. Engineered Materials Handbook, (ASM International, Materials Park, OH, 1999), pp. 167–171

W. D. Callister Jr., 2003. Materials Science and Engineering—An Introduction, 6th edn. (New York: Wiley), Sections 6.1–6.12, 8.1–8.4

A. Ravaglioli, A. Krajewski, Bioceramics, Published by Chapman & Hall, 3rd edition; page: 100–101, (1991)

R. Dembczynski, T. Jankowski, J. Biomater. Sci., Polym. Ed., 12(8), 1051 (2001)

J.M. Tang, W.I. Lee, G.S. Springer, J Compos. Mater., 27, 421 (1987)

K. Uhl, B. Lucht, H. Jeong, D.K. Hsu, Review of progress in quantitative nondestructive evaluation, 7B, 1075 (1988)

K.J. Bowles, S. Frimpong, J. Compos. Mater., 26(10), 1487 (1992)

A.M. Rubin, K.L. Jerina, Compos. Eng., 3, 601 (1993)

Acknowledgment

DRDO ER & IPR Division, New Delhi for partially supporting the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pal, K., Bag, S. & Pal, S. Development of porous ultra high molecular weight polyethylene scaffolds for the fabrication of orbital implant. J Porous Mater 15, 53–59 (2008). https://doi.org/10.1007/s10934-006-9051-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-006-9051-9