Abstract

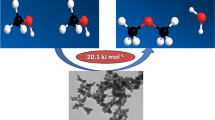

Rice husk silica modified with Ag (RH-Ag) and its calcined form, RH-Ag(C) are heterogeneous catalysts prepared from rice husk. The sodium silicate was extracted from rice husk using a simple solvent extraction technique. Silver was added during the precipitation of the gel to form RH-Ag. Calcination of RH-Ag yielded RH-Ag(C). RH-Ag and RH-Ag(C) was found to have a well defined amorphous phase and a crystalline phase. TEM analysis showed that silver was encapsulated into the silica matrix. Well defined mesoporous channels were found in RH-Ag(C). The EDX analysis showed that silver was indeed incorporated in the matrix of RH-Ag but it was not homogenously distributed. The specific surface area of RH-Ag and RH-Ag(C) was found to be 447 and 419 m2 g−1 respectively. The cation exchange capacity (CEC) for RH-Ag was found to be 0.470 mmol g−1 which was higher than that of RH-Ag(C) with 0.273 mmol g−1. Both the CEC and the BET values for RH-Ag(C) was consistent with the calcination process. Catalysis of benzyl alcohol using RH-Ag and RH-Ag(C) gave two products which were identified as benzaldehyde and dibenzyl ether. Percentage conversion was higher when the reaction was conducted with pure oxygen (14.0%) than in open air (0.60%). Overall, RH-Ag(C) was found to be a better catalyst for the formation of dibenzyl ether. The optimum weight and time of reaction for the oxidation was found to be 0.3 g and 3 h respectively for both catalysts. It was found that even in an inert atmosphere, 13% of benzaldehyde was obtained with RH-Ag(C) as catalyst. Mechanisms for the formation of benzaldehyde under oxygen and inert atmosphere and the condensation mechanism assisted by the presence of the Ag on the surface of the catalyst have been suggested.

Similar content being viewed by others

References

A. Takahasi, Appl. Catal. A: Gen. 294, 34 (2005)

A. Gang, Appl. Catal. B: Environ. 40, 101 (2003)

Z. Qu, J. Catal. 229, 446 (2005)

Z. Yang, J. Li, X. Yang, X. Xie, Y. Wu, J. Mol. Catal. A: Chem. 241, 15 (2005)

R. Yamamoto, Y. Sawayama, H. Shibahara, Y. Ichihashi, S. Nishiyama, S. Tsuruya, J. Catal. 234, 308 (2005)

L.F. Liotta, A.M. Venezia, Catal. Today 66, 271 (2001)

H.K. Fua, BSc. Thesis, Universiti Sains Malaysia, Malaysia (2003)

T.H. Liou, Mater. Sci. Eng. A 364, 313 (2004)

F.W. Chang, M.T. Tsay, S.P. Liang, Appl. Catal. A: Gen. 209, 217 (2001)

F.W. Chang, W.Y. Kuo, H.C. Yang, Appl. Catal. A: Gen. 288, 53 (2005)

F.W. Chang, W.Y. Kuo, K.C. Lee, Appl. Catal. A: Gen. 246, 253 (2003)

D. Prasetyoko, Z. Ramli, S. Endud, H. Hamdan, B. Sulikowski, Waste Manage. 26, 1173 (2006)

F. Adam, J.H. Chua, J. Colloid Int. Sci. 280, 55 (2004)

L.F. Cheah, BSc. Thesis, Universiti Sains Malaysia, Malaysia (2005)

G. Socrates, Infrared and Raman Characteristic Group Frequencies – Tables and Charts, 3rd edn. (John Wiley & Sons, Ltd. 2004), p. 244

M.S. Ghattas, J. Mol. Catal. A: Chem. 248, 175 (2006)

T.L. Slager, B.J. Lindgren, A.J. Mallmann, R.G Greenler, J. Phys. Chem. 76, 940 (1972)

Y. Kobaysahi, H. Katakami, E. Mine, D. Nagao, M. Konno, L.M. Liz-Marzàn, J. Colloid Int. Sci. 283, 392 (2005)

M.I. Saleh, F. Adam, I.Ab. Rahman, in Seramik Nusantara, ed. R. Othman (Universiti Sains Malaysia, Penang, 1990), p. 261

M.I. Saleh, F. Adam, J. Am. Oil Chem. Soc. 71, 1363 (1994)

F. Adam, S. Ravendran, J. Am. Oil Chem. Soc. 77, 437 (2000)

X. She, M.F. Stephanopoulos, J. Catal. 237, 79 (2006)

B.K. Hodnett, Heterogeneous Catalytic Oxidation – Fundamental and Technological Aspects of the Selective and Total Oxidation of Organic Compounds (John Wiley & Sons. Ltd., 2000)

J.R. Anderson and M. Boudart, Catalysis – Science and Technology, vol 2 (Springer-Verlag, 1981)

N. Narender, K.V.V.K. Mohan, S.J. Kulkarni, I.A.K. Reddy, Catal. Commun. 7, 583 (2006)

R.J. Madix, Science 233, 1159 (1986)

F. Adam, S. Balakrishnan, P.L. Wong, J. Phys. Sci. 17(2), 1 (2006)

A.E. Ahmed, F. Adam, Micropor. Mesopor. Mater. Doi: 10.1016/j.micromeso.2007.01.055

A. Davydov, in Molecular Spectroscopy of Oxide Catalyst Surfaces, ed. by N.T. Sheppard (John Wiley and Sons, 2003), pp. 421–536

Acknowledgements

The authors would like to express their thanks to Leong Guan Rice Mill Sdn. Bhd, Penang for providing the rice husk. We would also like to thank the Malaysian Government for the IRPA grant (09-02-05-2148 EA004) and the Ministry of Education, Malaysia for the FRGS (Account 304.PKIMIA.670005) grant which partly supported this work. We thank the Sudan University of Science and Technology for a scholarship to Adil Elhag Ahmed.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adam, F., Ahmed, A.E. & Min, S.L. Silver modified porous silica from rice husk and its catalytic potential. J Porous Mater 15, 433–444 (2008). https://doi.org/10.1007/s10934-007-9106-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-007-9106-6