Abstract

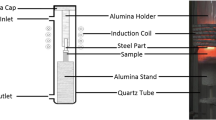

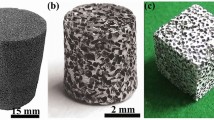

A new nickel-based porous structure, exhibiting a bi-modal pore size distribution, has been developed through the combination of nickel foam (INCOFOAM) with sintered nickel filamentary powder (T255). Sintering was carried out in the 900–980 °C temperature range in a vacuum environment. These bi-modal nickel samples were examined for their microstructure, hydraulic behaviour including capillary head and permeability, specific surface area (SAA), and overall porosity. The incorporation of a layer of sintered nickel filamentary powder (T255) onto the nickel foam was shown to increase both the specific surface area and capillary pumping pressure of the foam, while simultaneously maintaining high porosity and liquid permeability. Both the sintering temperature and the degree of nickel powder coverage were determined to be critical factors contributing to the properties of these bi-modal nickel porous structures.

Similar content being viewed by others

References

P.D. Dunn, D.A. Reay, Heat Pipes, 4th edn. (Pergamon, 1994)

D.L. Britton, in Nickel Hydroxide Electrodes, vol. 90(4), ed. by D.A. Corrigan, A.H. Zimmerman (The Electrochemical Society Inc., Pennington, NJ, 1990), p. 234

V.I. Chani, Q. Yang, D. Wilkinson, G.C. Weatherly, J. Power Sources 142, 370–381 (2005)

A. Gil, A. Diaz, L.M. Gandia, M. Montes, Appl. Catal. A: Gen. 109, 167–179 (1994)

R.M. de Almeida, H.V. Fajardo, D.Z. Mezalira, G.B. Nuernberg, L.K. Noda, L.F.D. Probst, N.L.V. Carreno, J. Mol. Catal. A: Chem. 259, 328–335 (2006)

P. Brennecke, H.H. Ewe, Energy Convers. Manage. 31(6), 585–594 (1991)

D. Queheillalt, D.D. Hass, D. Sypeck, H.N.G. Wadley, J. Mat. Res. 16(4), 1028–1036 (2001)

O.L. Get’man, L.I. Chernyshev, Powder Metall. Metal Ceram. 42(11–12), 630–637 (2003)

A.Y. Zaitsev, D.S. Wilkinson, G.C. Weatherly, T.F. Stephenson, J. Power Sources 123, 253–260 (2003)

W.H. Zhu, P. Durben, B. Tatarchuk, J. Power Source 111, 221–231 (2002)

K.C. Leong, C.Y. Liu, J. Porous Mater. 4, 303–308 (1997)

E.G. Reimbrecht, P. Wendhausen, M.C. Fredel, E. Basso, Key Eng. Mater. 189–191, 455–460 (2001)

M. Tane, S.K. Hyun, H. Nakajima, J. Appl. Phys. 97(103701), 1–4 (2005)

S.K. Hyun, M. Murakami, H. Nakajima, Mater. Sci. Eng. A299, 241 (2001)

S.W. Chi, Heat Pipe Theory and Practice: A Sourcebook (McGraw-Hill Book Company, NY, 1997)

A. Gupta, G. Upadhya, Adv. Electron. Packag. 2, 2129–2137 (1999)

B.D. Marcus, Theory and Design of Variable Conductance Heat Pipe, Report No. CR-2018 (NASA, Washington, DC, 1972)

Q.M. Yang, V.A. Ettel, J. Babjak, D.K. Charles, M.A. Mosoiu, J. Electrochem. Soc. 150(4), A543–A550 (2003)

Inco Special Products, http://www.incosp.com (2007)

C. Chan, H. Salt, Capillary Head and Permeability of Wicks with Single or Multiple Sized Pores (Commonwealth Scientific and Industrial Research Organisation, Australia, 1989)

G. Canti, G.P. Celata, M. Cumo, M. Furrer, Rev. Gen. Therm. 37, 5–16 (1998)

Douglas Charles, INCOLIB-#150901, 2006

S. Brunauer, P.H. Emmett, E. Teller, J. Am. Chem. Soc. 60, 309 (1938)

Acknowledgement

The authors would like to express their appreciation to Dr. Quan Yang, at Research and Development, Vale Inco located in Mississauga, Canada, for providing technical advice and materials for the experiment. Special thanks go to Mr. Douglas Charles, at CVRD Inco, for conducing specific surface area tests using the BET method.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, X., Franchi, G. & Cai, F. Characterization of porous bi-modal Ni structures. J Porous Mater 16, 165–173 (2009). https://doi.org/10.1007/s10934-007-9181-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-007-9181-8