Abstract

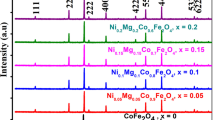

This paper presents a low temperature (130 and 160 °C) synthesis route to prepare the spinel phase CoFe2O4 nanoparticles and nanorods. A one-dimensional (1-D) structure of Co-ferrite was successfully synthesized using Cetyl Trimethyl Ammonium Bromide (CTAB) as a surfactant at temperature 160 °C. Structural, electrical, and magnetic measurements have been performed using X-ray diffraction (XRD), Fourier Transform Infrared Spectroscopy (FT-IR), Scanning Electron Microscopy (SEM), and the Vibrating Sample Magnetometer (VSM). XRD patterns show a pure spinel (fcc) structure, showing a complete phase formation at a low temperature of 160 °C, without any subsequent sintering. Average crystallite sizes have been calculated by Sherrer’s and Williamson-Hall methods. As prepared CoFe2O4 nanorods exhibited a uniform shape of diameter 60–80 nm and 600–900 nm in length. The FTIR spectrum for Co-ferrite nanorods shows two intrinsic lattice absorption bands for tetrahedral and octahedral sublattices. DC electrical resistivity of CoFe2O4 nanorods is high up to ∼108 (Ω-cm), as compared to CoFe2O4 nanoparticles (∼107 Ω-cm) at 373 K. Dielectric parameters were measured using a LCR meter, in the frequency range of 1 kHz to 5 MHz. The real and imaginary part of the dielectric constant (ε′ and ε″) and dielectric loss tangent (tanδ) reduces for CoFe2O4 nanorods in comparison to nanoparticles, and has a value of 13.6 and 0.0416, respectively. Magnetic properties were characterized by VSM under a field of 10 kOe and showed that the 1-D structure reduces the magnetization of nanocrystalline CoFe2O4 from 65 emu/gm to 54 emu/gm.

Similar content being viewed by others

References

Nlebedim, I.C., Snyder, J.E., Moses, A.J., Jiles, D.C.: J. Magn. Magn. Mater. 322, 3938–3942 (2010)

Zhigang, J., Daping, R., Rongsun, Z.: Mater. Lett. 66, 128–131 (2012)

Gunjakar, J.L., More, A.M., Gurav, K.V., Lokhande, C.D.: Appl. Surf. Sci. 254, 5844–5848 (2008)

Goha, S.C., Chiaa, C.H., Zakariaa, S., Yusoffa, M., Hawa, C.Y., Ahmadia, Sh., Huangb, N.M., Lim, H.N.: Mater. Chem. Phys. 120, 31–35 (2010)

Sankaranarayana, V.K., Sreekumar, C.J.: Curr. Appl. Phys. 3, 205–208 (2003)

Suginoto, M.: J. Am. Ceram. Soc. 82, 269 (1999)

Bate, G.: J. Magn. Magn. Mater. 100, 413 (1991)

Pileni, M.P.: Adv. Funct. Mater. 11, 323 (2001)

Xu, Y., Wei, J., Yao, J., Fu, J., Xue, D.: Mater. Lett. 62, 1403–1415 (2008)

Zhang, L.Y., Xue, D.S., Xu, X.F., Gui, A.B.: J. Magn. Magn. Mater. 294, 10 (2005)

Wang, Z., Liu, X., Lv, M., Chai, P., Liu, Y., Zhou, X.: J. Phys. Chem. C 112, 511–517 (2008)

Cai, W., Wan, J.Q.: J. Colloid Interface Sci. 305, 366–370 (2007)

Young, W.J., Jae, H.P., Hong, R.J., Sung, J.C., Wan, J.L.: Mater. Sci. Eng. B, Solid-State Mater. Adv. Technol. 147, 7–12 (2008)

Ji, G.B., Tang, S.L., Ren, S.K., Zhang, F.M., Gu, B.X., Gu, Y.W.: J. Cryst. Growth 270, 156 (2004)

Hiti, M.El., Abdeen, A.: Mater. Sci. Technol. 14, 417 (1998)

Gul, I.H., Maqsood, A., Naeem, A., Naeem, A.M.: J. Alloys Compd. 507, 201 (2010)

Byrappa, K., Adschiri, T.: Prog. Cryst. Growth Charact. Mater. 53, 117–166 (2007)

Yüksel, K., Furkan, A., Muhammed, T., Resul, Y., Mustafa, Ö.: Ceram. Int. 38, 3625–3634 (2012)

Baykal, A., et al.: J. Alloys Compd. 464, 514–518 (2008)

Shen, X., et al.: Trans. Nonferr. Met. Soc. China 19, 1588–1592 (2009)

Elkestawy, M.A., Abdel Kader, S., Amer, M.A.: J. Phys. B, At. Mol. Phys. 405, 619–624 (2010)

Suryanarayan, C., Grant, N.G.: X-ray Diffraction: A Practical Approach. Plenum, New York (1998)

Xiao, S.H., Jiang, W.F., Li, L.Y., Li, X.J.: Mater. Chem. Phys. 106, 82 (2007)

Qu, Y.Q., Yang, H.B., Yang, N., Fan, Y.Z., Zhu, H.Y., Zou, G.T.: Mater. Lett. 60, 548 (2006)

Gul, I.H., Maqsood, A., Abbasi, A.Z., Amin, F.M., Rehman, M.A.: J. Magn. Magn. Mater. 311, 494 (2007)

El-Sayed, A.M.: Ceram. Int. 28, 651 (2002)

Ahlawat, A., et al.: J. Magn. Magn. Mater. 323, 2049–2054 (2011)

Batoo, K.M., Kumar, M.S., Lee, C.G., Alimuddin: J. Alloys Compd. 480, 596 (2009)

Khandekara, M.S., Kambale, R.C., Patil, J.Y., Kolekar, Y.D., Suryavanshia, S.S.: J. Alloys Compd. 509, 1861–1865 (2011)

Verma, A., Thakur, O.P., Prakash, C., Goel, T.C., Mendiratta, R.G.: Mater. Sci. Eng. B, Solid-State Mater. Adv. Technol. 116, 1 (2005)

Lee, K.H., Cho, D.H., Jeung, S.S.: J. Mater. Sci. Lett. 16, 83 (1997)

Koop’s, C.: Phys. Rev. 83, 121 (1951)

Mohamed, R.M., Rashad, M.M., Haraz, F.A., Sigmund, W.: J. Magn. Magn. Mater. 322, 2058 (2010)

Iwachi, K.: Jpn. J. Appl. Phys. 10, 1520 (1971)

Chourashiya, M.G., Patil, J.Y., Pawar, S.H., Jadhav, L.D.: Mater. Chem. Phys. 109, 39 (2008)

Jia, Z., et al.: Mater. Lett. 66, 128–131 (2012)

Xiangyu, H., Jing, F., Xianodong, X., Milin, Z.: J. Alloys Compd. 491, 258–263 (2010)

El-Okr, M.M., Salem, M.A., Salim, M.S., El-Okr, R.M., Ashoush, M., Talaat, M.: J. Magn. Magn. Mater. 323, 920–926 (2011)

Zhen, L., He, K., Xu, C.Y., Shao, W.Z.: J. Magn. Magn. Mater. 320, 2672–2675 (2008)

Lawrence, K., Manoranjan, K.: J. Magn. Magn. Mater. 323, 2042–2048 (2011)

Acknowledgements

The authors would like to acknowledge TWAS, Italy, the Higher Education Commission (HEC) Islamabad, Pakistan, and the Pakistan Science Foundation (PSF) Project. No. 147, for providing financial support for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pervaiz, E., Gul, I.H. & Anwar, H. Hydrothermal Synthesis and Characterization of CoFe2O4 Nanoparticles and Nanorods. J Supercond Nov Magn 26, 415–424 (2013). https://doi.org/10.1007/s10948-012-1749-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-012-1749-0