Abstract

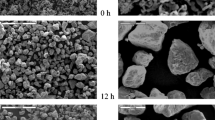

Mn50Bi50 alloy was prepared using arc melting method with subsequent homogenization treatment. The homogenized alloy was crushed and subjected to jet mill at different feed rates. The weight fraction of the LTP MnBi phase determined by the Rietveld refinement of the XRD pattern was found to be 89% in the as-homogenized and crushed alloy. The crushed alloy was subjected to jet milling at different feed rates from 0.5 to 1.5 g/min. Structural studies show that increase in feed rate leads to phase decomposition. Magnetic studies show that as-homogenized crushed alloy exhibits a magnetization of 60 emu/g. Jet milling leads to increase in coercivity and a decrease in magnetization. However, it was found that increase in the feed rate during jet milling leads to decrease of both coercivity and magnetization. Microstructural studies show that jet milling leads to decrease in particle size. Jet milling done at a lower feed rate helps in yielding the lowest average particle size compared to remaining feed rates in the Mn-Bi alloy. The spin reorientation transition temperature of the Mn-Bi alloy decreases with jet milling and varies at different feed rates. The coercivity of the Mn-Bi powder jet milled with a lower feed rate increases from 14.7 kOe at room temperature to 19.4 kOe at 400 K.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available within the article.

References

Guo, X., Altounian, Z., Stromolsen, J.O.: J. Appl. Phys. 69(8), 6067 (1991)

Albert, P.A., Carr, W.J.: J. Appl. Phys. 32, S201 (1961)

Guo, X., Chena, X., Altounian, Z., Stromolsen, J.O.: Phys. Rev. B. 46, 14578 (1992)

Yang, J., Yang, W., Shao, Z., Liang, D., Zhao, H., Xia, Y., Yang, Y.: Chin. Phys. B. 27, 117503 (2018)

Chen, T., Stutius, W.: IEEE Trans. Magn. MAG-10, 581 (1974)

Rama Rao, N.V., Gabay, A.M., Hadjipanayis, G.C.: J. Phys. D. Appl. Phys. 46, 062001 (2013)

Saito, T., Nishimura, R., Hamane, D.N.: J. Magn. Magn. Mater. 349, 9 (2014)

Xiang, Z., Song, Y., Pan, D., Shen, Y., Qian, L., Luo, Z., Liu, Y., Yang, H., Yen, H., Lu, W.: J. Alloys and Comp. 744, 432 (2018)

Nguyen, P., Jin, S., Berkowitz, A.E.: J. Appl. Phys. 115, 17A756 (2014)

Yin, F., Gu, N., Shigematsu, T., Nakanishi, N.: J. Mater. Sci. Technol. 12, 335 (1996)

Kavita, S., Ramakrishna, V.V., Srinivasan, A., Gopalan, R.: Mater. Res. Express. 3, 056102 (2016)

Chinnasamy, C., Jasinski, M.M., Ulmer, A., Li, W., Hadjipanayis, G., Liu, J.: IEEE Trans. Magn. 48, 3641 (2012)

Rama Rao, N.V., Gabay, A.M., Li, W.F., Hadjipanayis, G.C.: J. Phys. D. Appl. Phys. 46, 265001 (2013)

Rama Rao, N.V., Hadjipanayis, G.C.: J. Alloys and Comp. 629, 80–83 (2015)

Ramakrishna, V.V., Kavita, S., Gautam, R., Ramesh, T., Gopalan, R.: J. Magn. Magn. Mater. 458, 23 (2018)

Kanari, K., Sarafidis, C., Gjoka, M., Niarchos, D., Kalogirou, O.: J. Magn. Magn. Mater. 426, 691 (2017)

Li, X., Pan, D., Xiang, Z., Lu, W., Batalu, D.: Metals. 9, 441 (2019)

Kim, S.M., Moon, H., Jung, H., Kim, S.M., Lee, H.S., ChoiYim, H., Lee, W.: J. Alloys Compd. 708, 1245 (2017)

Tuunila, R., Nystrom, L.: Minerals Engineering. 11(I1), 1089 (1998)

Yang, J.B., Yelon, W.B., James, W.J., Cai, Q., Roy, S., Ali, N.: J. Appl. Phys. 91, 7866 (2002)

Choi, Y., Ryan, P.J., McGuire, M.A., Sales, B.C., Kim Appl, J.-W.: Phys. Lett. 112, 192411 (2018)

Yang, J.B., Yelon, W.B., James, W.J., Cai, Q., Kornecki, M., Roy, S., Ali, N., l’Heritier, P.: J. Phys. Cond. Matter. 14, 6509 (2002)

Suzuki, K., Wu, X., Ly, V., Shoji, T., Kato, A., Manabe, A.: J. Appl. Phys. 111, 07E303 (2012)

Rong, C.B., Poudyal, N., Liu, J.P.: Phys. Lett. A. 374, 3967 (2010)

Foldeaki, M., Koszegi, L., Dunlap, R.A.: J. Magn. Magn. Mater. 96, 29 (1991)

Xie, W., Polikarpov, E., Choi, J.P., Bowden, M.E., Sun, K., Cui, J.: J. Alloys Compd. 680, 1 (2016)

Zhang, D.T., Geng, W.T., Yue, M., Liu, W.Q., Zhang, J.X., Sundararajan, J.A., Qiang, Y.: J. Magn. Magn. Mater. 324, 1887 (2012)

Cao, J., Huang, Y.L., Hou, Y.H., Shi, Z.Q., Yan, X.T., Zhong, Z.C., Wang, G.P.: J. Magn. Magn. Mater. 473, 505 (2019)

Acknowledgments

The authors would like to acknowledge the constant support provided by Dr. G. Padmanabham, Director, and Dr. G. Sundararajan, Chairman TRC project.

Funding

This work has been carried out under TRC project (Grant No: AI/165/ARCI/2014) funded by the Department of Science and Technology (DST), Govt. of India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramakrishna, V.V., Kavita, S., Ramesh, T. et al. On the Structural and Magnetic Properties of Mn-Bi Alloy Jet Milled at Different Feed Rates. J Supercond Nov Magn 34, 733–737 (2021). https://doi.org/10.1007/s10948-020-05749-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-020-05749-y