Abstract

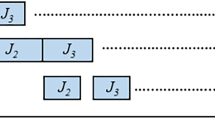

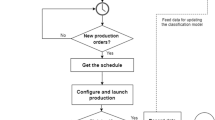

We deal with the scheduling of processes on a multi-product chemical batch production plant. Such a plant contains a number of multi-purpose processing units and storage facilities of limited capacity. Given primary requirements for the final products, the problem consists in dividing the net requirements for the final and the intermediate products into batches and scheduling the processing of these batches. Due to the computational intractability of the problem, the monolithic MILP models proposed in the literature can generally not be used for solving large-scale problem instances. The cyclic solution approach presented in this paper starts from the decomposition of the problem into a batching and a batch-scheduling problem. The complete production schedule is obtained by computing a cyclic subschedule, which is then repeated several times. In this way, good feasible schedules for large-scale problem instances are found within a short CPU time.

Similar content being viewed by others

References

Beck, J. C. (2002). Heuristics for scheduling with inventory: dynamic focus via constraint criticality. Journal of Scheduling, 5, 43–69.

Blömer, F., & Günther, H. O. (2000). LP-based heuristics for scheduling chemical batch processes. International Journal of Production Research, 38, 1029–1051.

Brucker, P. (2004). Scheduling algorithms. Berlin: Springer.

Brucker, P., & Hurink, J. (2000). Solving a chemical batch scheduling problem by local search. Annals of Operations Research, 96, 17–36.

Burkard, R. E., & Hatzl, J. (2005). Review, extensions and computational comparison of MILP formulations for scheduling of batch processes. Computers & Chemical Engineering, 29, 1752–1769.

Castro, P., Barbosa-Póvoa, A. P., & Matos, H. (2001). An improved RTN continuous-time formulation for the short-term scheduling of multipurpose batch plants. Industrial & Engineering Chemistry Research, 40, 2059–2068.

Castro, P., Barbosa-Póvoa, A. P., & Matos, H. (2003). Optimal periodic scheduling of batch plants using RTN-based discrete and continuous-time formulations: a case study approach. Industrial & Engineering Chemistry Research, 42, 3346–3360.

Floudas, C. A., & Lin, X. (2004). Continuous-time versus discrete-time approaches for scheduling of chemical processes: a review. Computers & Chemical Engineering, 28, 2109–2129.

Gentner, K. (2005). Dekompositionsverfahren für die ressourcenbeschränkte Projektplanung. Aachen: Shaker.

Gentner, K., Neumann, K., Schwindt, C., & Trautmann, N. (2004). Batch production scheduling in the process industries. In J. Y. T. Leung (Ed.), Handbook of scheduling: algorithms, models, and performance analysis (Chap. 48). Boca Raton: CRC Press.

Grunow, M., Günther, H. O., & Lehmann, M. (2002). Campaign planning for multi-stage batch processes in the chemical industry. OR Spectrum, 24, 281–314.

Honkomp, S. J., Lombardo, S., Rosen, O., & Pekny, J. F. (2000). The curse of reality: why process scheduling optimization problems are difficult in practice. Computers & Chemical Engineering, 24, 323–328.

Ierapetritou, M. G., & Floudas, C. A. (1998). Effective continuous-time formulation for short-term scheduling, 1: multipurpose batch processes. Industrial & Engineering Chemistry Research, 37, 4341–4359.

Kallrath, J. (2002). Planning and scheduling in the process industry. OR Spectrum, 24, 219–250.

Kondili, E., Pantelides, C. C., & Sargent, R. W. H. (1993). A general algorithm for short-term scheduling of batch operations, I: MILP formulation. Computers & Chemical Engineering, 17, 211–227.

Laborie, P. (2003). Algorithms for propagating resource constraints in AI planning and scheduling: existing approaches and new results. Artificial Intelligence, 143, 151–188.

Maravelias, C. T., & Grossmann, I. E. (2004). A hybrid MILP/CP decomposition approach for the continuous time scheduling of multipurpose batch plants. Computers & Chemical Engineering, 28, 1921–1949.

McCormick, S. T., & Rao, U. S. (1994). Some complexity results in cyclic scheduling. Mathematical and Computer Modelling, 20, 107–122.

Méndez, C. A., Cerdá, J., Grossmann, I. E., Harjunkoski, I., & Fahl, M. (2006). State-of-the-art review of optimization methods for short-term scheduling of batch processes. Computers & Chemical Engineering, 30, 913–946.

Neumann, K., & Schwindt, C. (2002). Project scheduling with inventory constraints. Mathematical Methods of Operations Research, 56, 513–533.

Neumann, K., Schwindt, C., & Trautmann, N. (2002). Advanced production scheduling for batch plants in process industries. OR Spectrum, 24, 251–279.

Neumann, K., Schwindt, C., & Zimmermann, J. (2003). Project scheduling with time windows and scarce resources. Berlin: Springer.

Pinedo, M. (2002). Scheduling: theory, algorithms, and systems. Upper Saddle River: Prentice Hall.

Potts, C. N., & Kovalyov, M. Y. (2000). Scheduling with batching: a review. European Journal of Operational Research, 120, 228–249.

Schwindt, C., & Trautmann, N. (2004). A priority-rule based method for batch production scheduling in the process industries. In D. Ahr, R. Fahrion, M. Oswald, & G. Reinelt (Eds.), Operations research proceedings 2003 (pp. 111–118). Berlin: Springer.

Schwindt, C., & Trautmann, N. (2006). A cyclic approach to large-scale short-term planning of multi-purpose batch plants. In M. Morlock, C. Schwindt, N. Trautmann, & J. Zimmermann (Eds.), Perspectives on operations research (pp. 225–238). Wiesbaden: Deutscher Universitäts-Verlag.

Schwindt, C., Fink, R., & Trautmann, N. (2007). A priority-rule based method for scheduling in chemical batch production. In Proceedings of the international conference on industrial engineering and engineering management (pp. 1347–1351), Singapore.

Shah, N., Pantelides, C. C., & Sargent, R. W. H. (1993a). A general algorithm for short-term scheduling of batch operations, II: computational issues. Computers & Chemical Engineering, 17, 229–244.

Shah, N., Pantelides, C. C., & Sargent, R. W. H. (1993b). Optimal periodic scheduling of multipurpose batch plants. Annals of Operations Research, 42, 193–228.

Timpe, C. H., & Kallrath, J. (2000). Optimal planning in large multi-site production networks. European Journal of Operational Research, 126, 422–435.

Wu, D., & Ierapetitrou, M. (2004). Cyclic short-term scheduling of multiproduct batch plants using continuous-time representation. Computers & Chemical Engineering, 28, 2271–2286.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Trautmann, N., Schwindt, C. A cyclic approach to large-scale short-term planning in chemical batch production. J Sched 12, 595–606 (2009). https://doi.org/10.1007/s10951-009-0107-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10951-009-0107-y