Abstract

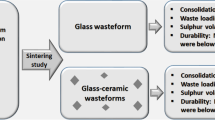

The pyrochemical process, which uses a dry method to recycle used nuclear fuel generates waste LiCl–KCl salt containing radioactive lanthanide elements. To reuse LiCl–KCl salt, the lanthanide elements are separated through a precipitation method promoted by oxygen sparging and the separated fission product of lanthanide oxide should be fabricated into durable wasteforms sustainable for several 1,000 years to store in a final geological repository. Herein, we report the fabrication of a borosilicate glass based wasteform with a glass matrix of SiO2–Al2O3–B2O3 having a high waste loading of 50 wt% lanthanide oxide. Th physical properties of four kinds of wasteforms having a different lanthanide oxide waste composition were evaluated. To investigate the long-term physical stability of each sample having 50 wt% lanthanide oxide waste loading, time–temperature–transformation (TTT) test was conducted at 500 and 700 °C for 60 and 180 h, and the physical properties were evaluated after each TTT test.

Similar content being viewed by others

References

Mcpheeters CC, Pierce RD, Mulcahey TP (1997) Prog Nucl Energy 31:175–186

Lee HS, Hur JM, Kim JG, Ahn DH, Cho YZ, Paek SW (2011) Energy Procedia 7:391–395

Lee HS, Park GI, Kang KH, Hur JM, Kim JG, Ahn DH, Cho YZ, Kim EH (2011) Nucl Eng Technol 43:317–328

Harrison MT, Simms HE, Jackson A, Lewin RG (2008) Radiochim Acta 96:295–301

Cho YZ, Yang HC, Park GH, Lee HS, Kim IT (2009) J Nucl Mater 384:256–261

Cho YZ, Lee TK, Eun HC, Choi JH, Kim IT, Park GI (2013) J Nucl Mater 437:47–54

Eun HC, Kim JH, Cho YZ, Choi JH, Lee TK, Park HS, Park GI (2013) J Nucl Mater. doi:10.1016/j.jnucmat.2013.08.021

Volkovich VA, Griffiths TR, Thied RC (2003) J Nucl Mater 323:49–56

Amamoto I, Kofuji H, Myochin M, Takasaki Y, Yano Y, Terai T (2009) J Nucl Mater 389:142–148

Donald IW, Metcalfe BL, Taylor RNJ (1997) J Mater Sci 32:5851–5887

Ojovan MI, Lee WE (2011) Metall Mater Trans 42A:837–851

Laverov NP, Omel’yanenko BI, Yudintsev SV, Stefanovsky SV, Nikonov BS (2013) Geol Ore Deposits 55:71–95

Mishra PK, De V, Ghongane DE, Valsala TP, Sonavane MS (2013) J Therm Anal Calorim 112:103–108

Park HS, Kim IT, Kim HY, Ryu SK, Kim JH (2007) Environ Sci Technol 41:1345–1351

Park HS, Kim IT, Cho YJ, Eun HC, Kim JH (2007) Environ Sci Technol 41:7536–7542

Park HS, Kim IT, Cho YJ, Eun HC, Lee HS (2008) Environ Sci Technol 42:9357–9362

Park HS, Cho IH, Eun HC, Kim IT, Cho YZ, Lee HS (2011) Environ Sci Technol 45:1932–1939

Bibler NE, Kinard WF, Boyce WT, Coleman CJ (1998) J Radioanal Nucl Chem 234:159–163

Kazemian H, Mallah MH, Maragheh MG (2004) J Radioanal Nucl Chem 261:619–623

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (No. 2012M2A8A5025801), and by the Energy Efficiency & Resources of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by Korea government Ministry of Knowledge Economy (2012T100100477).

Author information

Authors and Affiliations

Corresponding author

Additional information

Jung-Hoon Choi and In-Hak Cho have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Choi, JH., Cho, IH., Eun, HC. et al. Fabrication and physical properties of lanthanide oxide glass wasteform for the immobilization of lanthanide oxide wastes generated from pyrochemical process. J Radioanal Nucl Chem 299, 1731–1738 (2014). https://doi.org/10.1007/s10967-013-2863-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-013-2863-6