Abstract

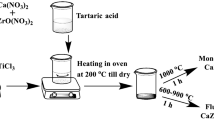

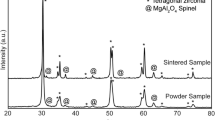

Yttrium-stabilized zirconia (Y0.08Zr0.92O1.96, YSZ) nanocrystalline powders were prepared by co-precipitation methods. Different precipitants (ammonium hydroxide, ammonium bicarbonate, oxalic acid, and urea) were used to study the effects of precipitants on co-precipitation synthesis of YSZ nanocrystalline powders. Thermogravimetric analysis-differential scanning calorimetry, powder X-ray diffraction, Fourier-transform infrared, scanning electron microscope, energy-dispersive spectrometer, Brunauer–Emmett–Teller, Barrett–Joyner–Halenda, and X-ray photoelectron spectroscopy analysis methods were employed to investigate the thermal decompositions, phase evolutions, micro-morphologies, surface areas, and elements analysis of the synthesized YSZ precursor powders or nanoparticles. Although different precipitants were used, the calcined products at 600 °C have nearly identical chemical compositions. The crystallization temperature of the precursor powders to evolve to cubic phase is the lowest (about 400 °C) when ammonium hydroxide is used as a precipitant, while it is about 500 °C in the case of other three types of precipitants (ammonium bicarbonate, oxalic acid, and urea) that were used. Ammonium bicarbonate cannot precipitate ZrO2+ effectively in the solution, resulting in the formation of cubic Y0.18Zr0.82O1.91 at 1000 °C. Despite the time-consuming co-precipitation process, urea was proved to be the optimal precipitant in terms of the fabrication of nanocrystalline YSZ powders with designed Y/Zr/O molar ratio, large surface area, small crystallite size, and well dispersion.

Highlights

-

The phase transition (amorphous to cubic phase) temperature of the obtained YSZ precursor powders is as low as around 400 °C in the case of ammonium hydroxide co-precipitation method, while it is around 500 °C when ammonium bicarbonate, oxalic acid, and urea are used as precipitants.

-

Ammonium bicarbonate cannot precipitate ZrO2+ effectively in the solution, resulting in the formation of cubic Y0.18Zr0.82O1.91 at 1000 °C.

-

Despite the time-consuming co-precipitation process, urea was proved to be the optimal precipitant to prepare YSZ nanocrystalline powders with designed Y/Zr/O molar ratio, large surface area, small crystallite size, and well dispersion.

Similar content being viewed by others

References

Wu Y, Bandyopadhyay A, Bose S (2004) Processing of alumina and zirconia nano-powders and compacts. Mater Sci Eng A 380(1–2):349–355

Mebrahitom Asmelash G, Mamat O, Ahmad F, Prasada Rao AK (2015) Thermal shock and fatigue behavior of pressureless sintered Al2O3–SiO2–ZrO2 composites. J Adv Ceram 4(3):190–198

Blaese D, Garcia DE, Guglielmi P, Hotza D, Fredel MC, Janssen R (2015) ZrO2 fiber-matrix interfaces in alumina fiber-reinforced model composites. J Eur Ceram Soc 35(5):1593–1598

Wang L, Shao F, Zhong XH, Ni JX, Yang K, Tao SY, Wang Y (2018) Tailoring of self-healing thermal barrier coatings via finite element method. Appl Surf Sci 431:60–74

Wang J, Sun J, Zhang H, Dong S, Jiang J, Deng L, Zhou X, Cao X (2018) Effect of spraying power on microstructure and property of nanostructured YSZ thermal barrier coatings. J Alloy Compd 730:471–482

Białas A, Kondratowicz T, Drozdek M, Kuśtrowski P (2015) Catalytic combustion of toluene over copper oxide deposited on two types of yttria-stabilized zirconia. Catal Today 257:144–149

Liu C, Zhang H, Xia J, Li Z (2013) Synthesis and characterization of Zr0.85Y0.15O1.925-La9.33Si6O26 composite electrolyte for application in SOFCs. J Adv Ceram 1(4):327–335

Carneiro JSA, Brocca RA, Lucena MLRS, Nikolla E (2017) Optimizing cathode materials for intermediate-temperature solid oxide fuel cells (SOFCs): Oxygen reduction on nanostructured lanthanum nickelate oxides. Appl Catal B 200:106–113

Huang Z, Qi J, Zhou M, Gong Y, Shi Q, Yang M, Han W, Cao Z, Peng S, Lu T (2018) A facile solvothermal method for high-quality Gd2Zr2O7 nanopowder preparation. Ceram Int 44(2):1334–1342

Arora A (2004) Ceramics in nanotech revolution. Adv Eng Mater 6(4):244–247

Xi X, Abe H, Naito M (2014) Effect of composition on microstructure and polarization resistance of solid oxide fuel cell anode Ni-YSZ composites made by co-precipitation. Ceram Int 40(10):16549–16555

Aruna ST, Balaji N, Shri Prakash B (2011) Low temperature assisted chemical coprecipitation synthesis of 8YSZ plasma sprayable powder for solid oxide fuel cells. Int J Hydrogen Energy 36(22):14963–14970

Zhang Y, Binner J, Rielly C, Vaidhyanathan B (2014) Comparison of spray freeze dried nanozirconia granules using ultrasonication and twin-fluid atomisation. J Eur Ceram Soc 34(4):1001–1008

Taherian M, Rojaee R, Fathi M, Tamizifar M (2014) Effect of different sol-gel synthesis processes on microstructural and morphological characteristics of hydroxyapatite-bioactive glass composite nanopowders. J Adv Ceram 3(3):207–214

Zhang F, Batuk M, Hadermann J, Manfredi G, Mariën A, Vanmeensel K, Inokoshi M, Van Meerbeek B, Naert I, Vleugels J (2016) Effect of cation dopant radius on the hydrothermal stability of tetragonal zirconia: grain boundary segregation and oxygen vacancy annihilation. Acta Mater 106:48–58

Zeng M, Ma Y, Wang Y, Pei C (2012) The effect of precipitant on co-precipitation synthesis of yttrium aluminum garnet powders. Ceram Int 38(8):6951–6956

Hsu YW, Yang KH, Chang KM, Yeh SW, Wang MC (2011) Synthesis and crystallization behavior of 3mol% yttria stabilized tetragonal zirconia polycrystals (3Y-TZP) nanosized powders prepared using a simple co-precipitation process. J Alloy Compd 509(24):6864–6870

Han X, Liang Z, Feng L, Wang W, Chen J, Xue C, Zhao H (2015) Co-precipitated synthesis of Al2O3–ZrO2 composite ceramic nanopowders by precipitant and drying method regulation: a systematic study. Ceram Int 41(1):505–513

Wang Z, Zhang W, You B, Yin M (2008) Effects of precipitant on microstructure and luminescent properties of Lu2O3:Eu3+ nanopowders and ceramics. Spectrochim Acta Part A 70(4):835–839

Ke S, Wang Y, Pan Z (2015) Effects of precipitant and surfactant on co-precipitation synthesis of Nd2Si2O7 ceramic pigment. Dyes Pigments 118:145–151

Zhang K, Liu HZ, Wu YT, Hu WB (2008) Co-precipitation synthesis and luminescence behavior of Ce-doped yttrium aluminum garnet (YAG:Ce) phosphor: the effect of precipitant. J Alloy Compd 453(1–2):265–270

Holcombe CE (1978) Yttria hydroxy-salt binders. J Am Ceram Soc 61(11-1):481–486

Saito N, Matsuda S, Ikegami T (1998) Fabrication of transparent yttria ceramics at low temperature using carbonate-derived powder. J Am Ceram Soc 81(8):2023–2028

Sordelet D, Akinc M (1988) Preparation of sphercal, monosized Y2O3 precursor particles. J Colloid Interf Sci 122(1):47–59

Patil DS, Prabhakaran K, Durgaprasad C, Gokhale NM, Samui AB, Sharma SC (2009) Synthesis of nanocrystalline 8 mol% yttria stabilized zirconia by the oleate complex route. Ceram Int 35(1):515–519

Mahendran R, Kumaresh Babu SP, Natarajan S, Manivannan S, Vallimanalan A (2017) Phase transformation and crystal growth behavior of 8mol% (SmO1.5, GdO1.5, and YO1.5) stabilized ZrO2 powders. Int J Min Mater 24(7):842–849

Hayashi K, Toyoda S, Takebe H, Morinaga K (1991) Phase-transformations of alumina derived from ammonium aluminum carbonate hydroxide (AACH). J Ceram Soc Jpn 99(7):550–555

Head EL, Holley Jr CE (1963) The preparation and thermal decomposition of the carbonates of Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, and Sc. (No. LADC-6082; CONF-405-3). Los Alamos Scientific Lab., New Mexico

Farhikhteh S, Maghsoudipour A, Raissi B, Mozaffari B (2008) Synthesis of high specific surface area YSZ (ZrO2–8Y2O3) nanocrystalline powder by modified polymerized complex method. J Sol-Gel Sci Technol 49(1):60–65

Ipek M, Zeytin S, Bindal C (2011) An evaluation of Al2O3–ZrO2 composites produced by coprecipitation method. J Alloy Compd 509(2):486–489

Heshmatpour F, Aghakhanpour RB (2011) Synthesis and characterization of nanocrystalline zirconia powder by simple sol–gel method with glucose and fructose as organic additives. Powder Technol 205(1–3):193–200

Amirsardari Z, Aghdam RM, Salavati-Niasari M, Shakhesi S (2016) Facile carbothermal reduction synthesis of ZrB2 nanoparticles: the effect of starting precursors. Mater Manuf Proc 31(2):134–140

Bineesh KV, Kim DK, Cho HJ, Park DW (2010) Synthesis of metal-oxide pillared montmorillonite clay for the selective catalytic oxidation of H2S. J Ind Eng Chem 16(4):593–597

Kuo CW, Lee KC, Yen FL, Shen YH, Lee HE, Wen SB, Wang MC, Stack MM (2014) Growth kinetics of tetragonal and monoclinic ZrO2 crystallites in 3 mol% yttria partially stabilized ZrO2 (3Y-PSZ) precursor powder. J Alloy Compd 592:288–295

Pandey AK, Biswas K (2014) Effect of agglomeration and calcination temperature on the mechanical properties of yttria stabilized zirconia (YSZ). Ceram Int 40(9):14111–14117

Mao J, Deng Z, Liu M, Deng C, Song J, Yang K (2017) Regional characteristics of YSZ coating prepared by expanded Ar/He/H plasma jet at very low pressure. Surf Coat Technol 328:240–247

Zhou Y, Yuan W, Huang Q, Huang W, Cheng H, Liu H (2015) Effect of Y2O3 addition on the phase composition and crystal growth behavior of YSZ nanocrystals prepared via coprecipitation process. Ceram Int 41(9):10702–10709

Dulina NA, Yermolayeva YV, Tolmachev AV, Sergienko ZP, Vovk M, Vovk EA, Matveevskaya NA, Mateychenko PV (2010) Synthesis and characterization of the crystalline powders on the basis of Lu2O3: Eu3+ spherical submicron-sized particles. J Eur Ceram Soc 30(7):1717–1724

Kafili G, Movahedi B, Milani M (2016) A comparative approach to synthesis and sintering of alumina/yttria nanocomposite powders using different precipitants. Mater Chem Phys 183:136–144

Jung YS, Yoon WL, Seo YS, Rhee YW (2012) The effect of precipitants on Ni-Al2O3 catalysts prepared by a co-precipitation method for internal reforming in molten carbonate fuel cells. Catal Commun 26:103–111

Dong X, Li F, Zhao N, Xiao F, Wang J, Tan Y (2016) CO2 hydrogenation to methanol over Cu/ZnO/ZrO2 catalysts prepared by precipitation-reduction method. Appl Catal B 191:8–17

Zinatloo-Ajabshir S, Salavati-Niasari M (2016) Preparation of nanocrystalline cubic ZrO2 with different shapes via a simple precipitation approach. J Mater Sci Mater Electron 27(4):3918–3928

Acknowledgements

This work was supported by the National Natural Science Foundation of the People’s Republic of China under Grant Nos. 11505122 and 11775152, the Science and Technology Innovation Team of Sichuan province under Grant No.15CXTD0025, and the Key Applied Basic Research (2017JY0329) of Sichuan province.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, Z., Han, W., Feng, Z. et al. The effects of precipitants on co-precipitation synthesis of yttria-stabilized zirconia nanocrystalline powders. J Sol-Gel Sci Technol 90, 359–368 (2019). https://doi.org/10.1007/s10971-019-04947-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-04947-y