Abstract

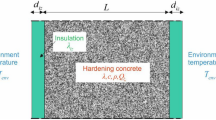

Simulation of thermal phenomena in rotational moulding is very important to follow the evolution of the temperature in various zones of this process. It was a question of modelling heat gradients developing in rotational moulding part. Thermal model tested take into account the temperature change (thermal transfer mechanism) of melting and crystallization pseudo-stages (enthalpy method). Series of tests in polyamide 11 (PA11) were carried out by means of rotational moulding STP LAB, and non-isothermal crystallization kinetics of rotational moulding PA11 grade are measured and analysed by DSC technique type TAQ20. A result of non-isothermal crystallization of the studied polyamide was confronted with Ozawa model. In order to test the validity degree of enthalpy method (layer to layer), another approach based on Ozawa model has also been used in the case of cooling pseudo-stage. As results, the rotational moulding of PA11 was successfully carried out. The simulation of the fusion and crystallization stages, by application of Ozawa model coupled with enthalpy method gave a good representation of experimental data.

Similar content being viewed by others

References

Crawford RJ. Rotational moulding of plastic. 2nd ed. Wiley and Sons: Research Studies Press Ltd; 1996. p. 3–9.

Aramazotti D. Rotational moulding. In: Miller E, editor. Plastics products design handbook. New York: Marcel Dekker; 1983.

Xin W, Harkin-Jones EH, Crawford RJ, Fatnes AM. Rotational moulding of metallocene polyethylenes. Plast Rubber Compos. 2000;29:340–8.

Tcharkhtchi A, Barcelo P, Mazabraud P, Jousse F, Kearns MP. Study of adhesion between two layers in multilayers rotomolded products. Adv Eng Mater. 2002;4:475–8.

Oliveira MJ, Cramez MC. Rotational molding of polyolefins: processing, morphology, and properties. J Macromol Sci Phys. 2001;40:457–71.

Kontopoulou M, Bisaria M, Vlachopoulos J. An experimental study of rotational molding of polypropylene/polyethylene copolymers. Int Polym Process. 1997;12:165–73.

Greco A, Maffezzoli A, Calò E, Massaro C, Terzi R. An investigation into sintering of PA6 nanocomposite powders for rotational moulding. J Therm Anal Calorim. 2011;. doi:10.1007/s10973-011-1916-8.

Crawford RJ, Gibson S. Rotational moulding: the basis for designers. http://file.seekpart.com/keywordpdf/2011/1/12/201111252045548.pdf. Accessed 17 July 2012.

Spence AG, Crawford RJ. The effect of processing variables on the formation and removal of bubbles in rotationally moulded products. Polym Eng Sci. 1996;36:993–1009.

Kontopoulou M, Vlachopoulos J. Melting and densification of thermoplastic powders. Polym Eng Sci. 2001;41:155–69.

Hu X, Bellehumeur CT. Modeling the morphology development of ethylene copolymers in rotational moulding. J Appl Polym Sci. 2006;102:5903–17.

Crawford RJ, Nugent PJ. Impact strength of rotationally moulded polyethylene articles. Plast Rubber Compos Process Appl. 1992;17:33–41.

Greco A, Maffezzoli A. Powder shape analysis and sintering behavior of high density polyethylene powders for rotational molding. J Appl Polym Sci. 2004;92:449–60.

Tcharkhtchi A, Chinesta F, Pérot E. Simulation of thermal phenomena on the interface molten polymer during rotational molding. Int Polym Process. 2004;19:296–302.

Zhou Y, Fernandez-Pello AC. An enthalpy-temperature hybrid method for solving phase-change problems and its application to polymer pyrolysis and ignition. Combust Theory Model. 2000;4:477–93.

Greco A, Maffezzoli A, Vlachopoulos J. Simulation of heat transfer during rotational molding. Adv Polym Tech. 2003;22:271–9.

Ozawa T. Kinetics of non-isothermal crystallization. Polymer. 1971;12:150–8.

Frank HP. Some oxidation characteristics of polypropylene. J polym sci. 1976;57:311–8.

Greco A, Maffezzoli A. Polymer melting and polymer powder sintering by thermal analysis. J Therm Anal Calorim. 2003;72:1167–74.

Wunderlich B. Termination of crystallization or ordering of flexible, linear macromolecules. J Therm Anal Calorim. 2012;. doi:10.1007/s10973-012-2326-2.

Cebeci T. Convective heat transfer. Springer: Horizons publishing; 2002.

Crank J, Nicolson P. A practical method for numerical evaluation of solutions of partial differential equations of the heat conduction type. Proc Camb Philos Soc. 1947;43:50–67.

Thomas JW. Numerical partial differential equations: finite difference methods. Texts in applied mathematics 22. New York: Springer-Verlag; 1995.

Wilmott P, Howison S, Dewynne J. The Mathematics of Financial Derivatives. A Student Introduction. Cambridge: Cambridge University Press; 1995.

Sarrabi S, Colin X, Tcharkhtchi A. Dégradation thermique du polypropylène au cours du rotomoulage. Matériaux et Techniques. 2008;96:253–61.

Van Krevelen DW. Properties of polymers. Amerstadem: Elsevier Scientific Publishing; 1976.

Williams JCL. In nylon plastics handbook. New York: Hanser Publishers; 1995.

Gogos G, Olson LG, Liu X, Pasham VR. New models for rotational molding of plastics. Polym Eng Sci. 1998;38:1387–98.

Gogos G, Olson LG, Liu X. Cycle time predictions for the rotational molding process with and without mold/part separation. Polym Eng Sci. 1999;39:617–29.

Bouralis J, Maeder G. Elaboration-structure-propriétés normalisation. Paris: Afnor-Nathan; 1997.

Facy G, Pompidou M. Méthodologie, production et normalisation. Paris: Afnor-Nathan; 1992.

Duffo P, Monasse B, Haudin JM. Cast film extrusion of polypropylene. Thermomechanical and physical aspects. J Polym Eng. 1991;10:151–229.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hafsaoui, S.L., Benziane, M. & Tcharkhtchi, A. Thermal transfer simulation regarding the rotational moulding of polyamide 11. J Therm Anal Calorim 112, 285–292 (2013). https://doi.org/10.1007/s10973-012-2806-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2806-4