Abstract

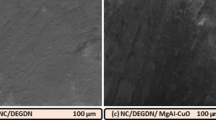

Glycidyl azide polymer (GAP) is a promising candidate for energetic binders in future solid propellants with minimum smoke signature, reduced pollution and low sensitivity. A series of GAP-modified nitrocellulose (NC) spherical powders were prepared by an internal solution method, and its properties have been studied. SEM characterization showed that the GAP-modified NC spherical powders exhibited high roundness rate, excellent fluidity and the favorable uniformity of its corresponding propellant. XRD analyses and DSC test indicated that GAP and NC molecular chain segment had a certain degree of compatibility, and GAP molecular had desirable plasticizing effect on NC. TG–FTIR–MS coupled method revealed that GAP-modified NC spherical powders had three decomposition stages, corresponding to the decompositions of O–NO2 groups, –N3 groups and the main chains of NC and GAP, respectively. The onset decomposition temperature of GAP-modified NC spherical powders was 5.67 °C higher than that of pure NC spherical powders, which was very important for its safety performance. The NO2, CO2 and NO were detected from the gas products of first decomposition stage, while CO, H2CO2, CH4, HCN and NH3 were identified from the gas products of second decomposition stage. Finally, CO and CO2 were produced from the third decomposition stage. The thermal decomposition process of GAP-modified NC spherical powders was presented.

Similar content being viewed by others

Abbreviations

- GAP:

-

Glycidyl azide polymer

- DINA:

-

Dinitroxyethylnitramine

- P(EO–THF):

-

Copolyether of ethylene oxide and tetrahydrofuran

- NC:

-

Nitrocellulose

- NG:

-

Nitroglycerin

- RDX:

-

Cyclotrimethylenetrinitramine

- CARBON:

-

Carbon black

- N100:

-

Triisocyanate

- TPB:

-

Triphenylbismuthine

- C2:

-

Centralite II

- TG:

-

Thermal gravimetric analysis

- DTG:

-

Differential thermogravimetry

- SEM:

-

Scanning electron microscopy

- DSC:

-

Differential scanning calorimetry

- XRD:

-

X-ray diffraction

- TG–FTIR–MS:

-

Thermogravimetric analysis/Fourier transform infrared spectroscopy/mass spectrometry

References

Reese DA, Groven LJ, Son SF. Formulation and characterization of a new nitroglycerin-free double base propellant. Propellants Explos Pyrotech. 2014;39:205–10.

Wu YG, Ge Z, Luo YJ. Properties and application of a novel type of glycidyl azide polymer modified double-base spherical powders. J Therm Anal Calorim. 2016;124:107–15.

Kazemi A, Hayaty M, Mousaviazar A, et al. The synthesis and characterization of polyvinyl nitrate as an energetic polymer and study of its thermal behavior. J Therm Anal Calorim. 2015;119:613–8.

Xu W, Wang X, Liu X, et al. Research progress in energetic binders. J Rocket Propuls. 2007;332:44–7.

Davenas A. Development of modern solid propellants. J Propul Power. 2003;19:1108–28.

Tang CJ, Lee Y, Litzinger TA. Simultaneous temperature and species measurements of the glycidyl azide polymer (GAP) propellant during laser-induced decomposition. Combust Flame. 1999;117:244–56.

Davidson J, Beckstead M. A mechanism and model for GAP combustion. In: 35th AIAA Aerospece sciences meeting and exhibit., Reno, NV, USA, Jan 6–9, 1997, AIAA paper 1997–0592.

Kumari D, Singh H, Patil M, et al. Synthesis, characterization, thermal and computational studies of novel tetra-azido esters as energetic plasticizers. Thermochim Acta. 2013;562:96–104.

Min BS, Kim CK, Ryoo MS, et al. Azide-bearing polymer-based solid composite propellant prepared by a dual curing system consisting of a urethane-forming reaction and a dipolar addition reaction. Fuel. 2014;136:165–71.

Pisharath S, Ang HG. Thermal decomposition kinetics of a mixture of energetic polymer and nitramine oxidizer. Thermochim Acta. 2007;459:26–33.

Kubota N, Sonobe T. Combustion mechanism of azide polymer. Propellants Explos Pyrotech. 1988;13:172–7.

Kumari D, Anjitha SG, Pant CS, et al. Synthetic approach to novel azido esters and their utility as energetic plasticizers. RSC Adv. 2014;4:39924–33.

Agrawal JP, Walley SM, Field JE. High-speed photographic study of the impact response of ammonium dinitramide and glycidyl azide polymer. J Propul Power. 1997;13:463–70.

Kubota N. Combustion of energetic azide polymers. J Propul Power. 1995;11:677–82.

Niehaus M. Compounding of glycidyl azide polymer with nitrocellulose and its influence on the properties of propellants. Propellants Explos Pyrotech. 2000;25:236–40.

Sun YL, Li SF. The effect of nitrate esters on the thermal decomposition mechanism of GAP. J Hazard Mater. 2008;154:112–7.

Zhao BB, Zhang TF, Ge Z, et al. Fabrication and thermal decomposition of glycidyl azide polymer modified nitrocellulose double base propellants. Sci China Chem. 2016;59:472–7.

Kim HJ, Lee SH, Kim S, et al. Membrane crystallinity and fuel crossover in direct ethanol fuel cells with Nafion composite membranes containing phosphotungstic acid. J Mater Sci. 2017;52:2400–12.

Moniruzzaman M, Bellerby JM, Mai N. The effect of light on the viscosity and molecular mass of nitrocellulose. Polym Degrad Stab. 2011;96:929–35.

Trache D, Khimeche K, Mezroua A, et al. Physicochemical properties of microcrystalline nitrocellulose from Alfa grass fibres and its thermal stability. J Therm Anal Calorim. 2016;124:1485–96.

Zhao XB, Du L, Zhang XP, et al. Compatibility and phase separation of polymer blends. Polym Bull. 2001;4:75–80.

Jin J, Wang H, Shu ZJ, et al. Impact of selective dispersion of intumescent flame retardant on properties of polypropylene blends. J Mater Sci. 2017;52(6):3269–80.

Li YW. Modified double base propellant[M]. Beijing: Ordnance Industry Press; 1970.

Tranchant J. Internal mechanism of the chemical evolution of nitrocellulose propellants:HypOtheses and consequences[C]. In: Symp Chem Probl Connected Stabil Explos, 6th. 1982: 1–20.

Oyumi Y, Brill TB. Thermal decomposition of energetic materials 22. The contrasting effects of pressure on the hight-rate thermolysis of 34 energetic compounds. Combust Flame. 1987;68:209–16.

Chen ZQ, Liu Y, Liu ZR, et al. An investigation on the kinetics and mechanism of the thermal decomposition of GAP. J Solid Rocked Technol. 2003;6:52–4.

Acknowledgements

This work was supported by the Natural National Science Foundation of China (51603156) and Wuhan Institute of Technology Scientific Research Foundation of China (k201406). And the authors also appreciate the Natural National Science Foundation of China (51373126).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, Y., Yi, Z., Luo, Y. et al. Fabrication and properties of glycidyl azide polymer-modified nitrocellulose spherical powders. J Therm Anal Calorim 129, 1555–1562 (2017). https://doi.org/10.1007/s10973-017-6387-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6387-0