Abstract

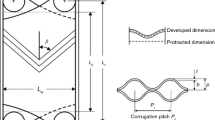

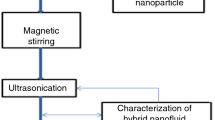

Brines (ethylene glycol, calcium chloride, propylene glycol and potassium acetate)-based hybrid (combinations of alumina, copper oxide, silica and titania with copper nanoparticles) nanofluids have been used as a secondary refrigerant to improve the heat transfer characteristics of the plate evaporator for milk chilling. Effect of nanoparticle combination, shape and size on heat transfer area, pump work, the ratio of heat transfer coefficient to pressure drop, coefficient of performance, performance index, thermal performance factor and exergetic efficiency has been examined theoretically. Copper oxide–copper hybrid nanofluid gives superior performance, while silica–copper hybrid nanofluid performs well in terms of exergetic efficiency. The maximum decrease in effective heat transfer area (5.9%) is found for propylene glycol brine-based copper oxide hybrid nanofluid. Percentage change in heat transfer area and performance index reduces with an increase in the particle size and is maximum for alumina–copper hybrid nanofluid. However, thermal performance factor increases with particle size. Brick-shaped particles show maximum changes in heat transfer area and performance index, while platelet-shaped particles show worse performance. The study reveals that the nanoparticle shape has a strong influence on the plate heat exchanger performance due to a significant deviation in surface area-to-volume ratio.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer area (m2)

- b :

-

Mean channel spacing (mm)

- c p :

-

Specific heat (J kg−1 K−1)

- D :

-

Diameter (mm)

- D h :

-

Hydraulic diameter (m)

- E :

-

Exergy rate (W)

- f :

-

Friction factor (dimensionless)

- G :

-

Mass velocity (kg s−1 m−2)

- h :

-

Specific enthalpy (J kg−1)

- J :

-

Comparison factor (m s−1 K−1)

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length (m)

- ṁ :

-

Mass flow rate (kg s−1)

- M :

-

Molecular weight

- n :

-

Shape function (dimensionless)

- N :

-

Avogadro number (mole−1)

- N p :

-

Number of passes (dimensionless)

- N t :

-

Number of plates (dimensionless)

- Nu:

-

Nusselt number (dimensionless)

- p :

-

Pressure (Pa)

- Q :

-

Heat transfer rate (W)

- r :

-

Radius (nm)

- s :

-

Specific entropy (J K−1)

- T :

-

Temperature (K)

- t :

-

Plate thickness (mm)

- U :

-

Overall heat transfer coefficient (W K−1 m−2)

- W :

-

Work transfer rate (W)

- Al2O3 :

-

Alumina

- CaCl2 :

-

Calcium chloride

- CuO:

-

Copper oxide

- COP:

-

Coefficient of performance

- EES:

-

Engineering equation solver

- EG:

-

Ethylene glycol

- HyNf:

-

Hybrid nanofluid

- KAC:

-

Potassium acetate

- LMTD:

-

Log mean temperature difference

- MWCNT:

-

Multiwalled carbon nanotube

- PHE:

-

Plate heat exchanger

- PG:

-

Propylene glycol

- PI:

-

Performance index

- TiO2 :

-

Titania

- TPF:

-

Thermal performance factor

- v%:

-

Volume percentage

- α :

-

Heat transfer coefficient (W K−1 m−2)

- β :

-

Chevron angle (°)

- ρ :

-

Density (kg m−3)

- η :

-

Efficiency (dimensionless)

- Ω:

-

Coefficient (dimensionless)

- Φ:

-

Volume fraction (dimensionless)

- µ :

-

Dynamic viscosity (Pa s)

- II:

-

Second

- a:

-

First particle

- b:

-

Second particle

- bf:

-

Basefluid

- ch:

-

Channel

- comp:

-

Compressor

- e:

-

Ambient

- eva:

-

Evaporator

- i:

-

Inlet

- nf:

-

Hybrid nanofluid

- o:

-

Outlet

- p:

-

Port

- r:

-

Refrigerant

References

Wang K, Eisele M, Hwang Y, Radermacher R. Review of secondary loop refrigeration systems. Int J Refrig. 2010;33:212–34.

Hillerns F. Thermophysical properties and corrosion behavior of secondary coolants. Atlanta: ASHRAE Winter Meeting; 2001. p. 1–6.

Bhattad A, Sarkar J, Ghosh P. Improving the performance of refrigeration systems by using nanofluids: a comprehensive review. Renew Sustain Energy Rev. 2018;82:3656–69.

Shadloo MS, Mahian O. Recent advances in heat and mass transfer. J Therm Anal Calorim. 2019;135:1611–5.

Mahian O, Bajestan EE, Poncet S. Nanofluid today. J Therm Anal Calorim. 2019;135:23–8.

Sarkar J, Ghosh P, Adil A. A review on hybrid nanofluids: recent research, development and applications. Renew Sustain Energy Rev. 2015;43:164–77.

Babar H, Ali HM. Towards hybrid nanofluids: preparation, thermophysical properties, applications, and challenges. J Mol Liq. 2019;281:598–633.

Yang L, Ji W, Zhang Z, Jin X. Thermal conductivity enhancement of water by adding graphene nanosheets: consideration of particle loading and temperature effects. Int Commun Heat Mass transf. 2019;109:104353.

Yang L, Mao M, Huang JN, Ji W. Enhancing the thermal conductivity of SAE 50 engine oil by adding zinc oxide nano-powder: an experimental study. Powder Technol. 2019;356:335–41.

Moldoveanu GM, Huminic G, Minea AA, Huminic A. Experimental study on thermal conductivity of stabilized Al2O3 and SiO2 nanofluids and their hybrid. Int J Heat Mass Transf. 2018;127:450–7.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems: a review. J Therm Anal Calorim. 2018;131:2027–39.

Rashidi S, Karimi N, Mahian O, Esfahani JA. A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J Therm Anal Calorim. 2019;135:1145–59.

Yang L, Huang JN, Ji W, Mao M. Investigations of a new combined application of nanofluids in heat recovery and air purification. Powder Technol. 2019. https://doi.org/10.1016/j.powtec.2019.10.053.

Kumar V, Sarkar J. Numerical and experimental investigations on heat transfer and pressure drop characteristics of Al2O3–TiO2 hybrid nanofluid in minichannel heat sink with different mixture ratio. Powder Technol. 2019;345:717–27.

Bhattad A, Sarkar J, Ghosh P. Experimentation on effect of particle ratio on hydrothermal performance of plate heat exchanger using hybrid nanofluid. Appl Therm Eng. 2019;162:114309.

Singh SK, Sarkar J. Energy, exergy and economic assessments of shell and tube condenser using hybrid nanofluid as coolant. Int Commun Heat Mass Transf. 2018;98:41–8.

Tiwari AK, Ghosh P, Sarkar J. Particle concentration levels of various nanofluids in plate heat exchanger for best performance. Int J Heat Mass Transf. 2015;89:1110–8.

Huang D, Wu Z, Sunden B. Effects of hybrid nanofluid mixture in plate heat exchangers. Exp Therm Fluid Sci. 2016;72:190–6.

Kumar V, Tiwari AK, Ghosh SK. Effect of variable spacing on performance of plate heat exchanger using nanofluids. Energy. 2016;114:1107–19.

Bhattad A, Sarkar J, Ghosh P. Exergetic analysis of plate evaporator using hybrid nanofluids as secondary refrigerant for low-temperature applications. Int J Exergy. 2017;24–1:1–20.

Kumar V, Tiwari AK, Ghosh SK. Exergy analysis of hybrid nanofluids with optimum concentration in a plate heat exchanger. Mater Res Express. 2018;5:065022.

Bhattad A, Sarkar J, Ghosh P. Energy-economic analysis of plate evaporator using brine-based hybrid nanofluids as secondary refrigerant. Int J Air-Cond Refrig. 2018;26(1):1850003-12.

Bhattad A, Sarkar J, Ghosh P. Energetic and exergetic performances of plate heat exchanger using brine based hybrid nanofluid for milk chilling application. Heat Transf. Eng. 2019; 1–14. https://doi.org/10.1080/01457632.2018.1546770.

Li CH, Peterson GP. The effect of particle size on the effective thermal conductivity of Al2O3–water nanofluids. J Appl Phys. 2007;101:044312.

Timofeeva EV, Routbort JL, Singh D. Particle shape effects on thermophysical properties of alumina nanofluids. J Appl Phys. 2009;106:014304.

Jeong J, Li C, Kwon Y, Lee J, Kim SH, Yun R. Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int J Refrig. 2013;36:2233–41.

Nazarabada MK, Goharshadi EK, Youssefi A. Particle shape effects on some of the transport properties of tungsten oxide nanofluids. J Mol Liq. 2016;223:828–35.

Nemati Z, Alonso J, Rodrigo I, Das R, Garaio E, García JÁ, Orue I, Phan M-H, Srikanth H. Improving the heating efficiency of iron oxide nanoparticles by tuning their shape and size. J Phys Chem C. 2018;122:2367–81.

Shaiq S, Maraj EN, Iqbal Z. A comparative analysis of shape factor and thermophysical properties of electrically conducting nanofluids TiO2–EG and Cu–EG towards stretching cylinder. Chaos Soliton Fract. 2019;118:290–9.

Yang L, Zhang Z, Du K. Heat transfer and flow optimization of a novel sinusoidal minitube filled with non-Newtonian SiC/EG–water nanofluids. Int J Mech Sci. 2019. https://doi.org/10.1016/j.ijmecsci.2019.105310.

Yang L, Ji W, Huang JN, Xu G. An updated review on the influential parameters on thermal conductivity of nanofluids. J Mol Liq. 2019. https://doi.org/10.1016/j.molliq.2019.111780.

Elias MM, Miqdad M, Mahbubul IM, Saidur R, Kamalisarvestani M, Sohel MR, Hepbasli A, Rahim NA, Amalina MA. Effect of nanoparticle shape on the heat transfer and thermodynamic performance of a shell and tube heat exchanger. Int Commun Heat Mass Transf. 2013;44:93–9.

Mahian O, Kianifar A, Heris SZ, Wongwises S. First and second laws analysis of a minichannel-based solar collector using boehmite alumina nanofluids: effects of nanoparticle shape and tube materials. Int J Heat Mass Transf. 2014;78:1166–76.

Arani AAA, Sadripour S, Kermani S. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluids in a sinusoidal–wavy mini-channel with phase shift and variable wavelength. Int J Mech Sci. 2017;128–129:550–63.

Hajabdollahi H, Hajabdollahi Z. Numerical study on impact behavior of nanoparticle shapes on the performance improvement of shell and tube heat exchanger. Chem Eng Res Des. 2017;125:449–60.

Xie H, Wang J, Xi T, Liu Y, Ai F, Wu Q. Thermal conductivity enhancement of suspensions containing nanosized alumina particles. J Appl Phys. 2002;91:4568–72.

Kim SH, Choi SR, Kim D. Thermal conductivity of metal-oxide nanofluids: particle size dependence and effect of laser irradiation. J Heat Transf. 2006;129:298–307.

Nguyen CT, Desgranges F, Roy G, Galanis N, Maré T, Boucher S, Mintsa HA. Temperature and particle-size dependent viscosity data for water-based nanofluids–hysteresis phenomenon. Int J Heat Fluid Flow. 2007;28:1492–506.

Mintsa HA, Roy G, Nguyen CT, Doucet D. New temperature dependent thermal conductivity data for water-based nanofluids. Int J Therm Sci. 2009;48:363–71.

Monfared M, Shahsavar A, Bahrebar MR. Second law analysis of turbulent convection flow of boehmite alumina nanofluid inside a double-pipe heat exchanger considering various shapes for nanoparticle. J Therm Anal Calorim. 2019;135:1521–32.

Klein SA. Engineering Equation Solver Professional. Version V10.042-3D, USA: F-Chart, 2016.

Zarringhalam M, Karimipour A, Toghraie D. Experimental study of the effect of solid volume fraction and Reynolds number on heat transfer coefficient and pressure drop of CuO–water nanofluid. Exp Therm Fluid Sci. 2016;76:342–51.

Huang D, Wu Z, Sunden B. Pressure drop and convective heat transfer of Al2O3/water and MWCNT/water nanofluids in a chevron plate heat exchanger. Int J Heat Mass Transf. 2015;89:620–6.

Kakac S, Liu H. Heat exchangers: selection, rating and thermal design. 2nd ed. Boca Raton: CRC Press LLC; 2002.

Chougule SS, Sahu SK. Model of heat conduction in hybrid nanofluid. ICECCN: IEEE: 2013.

Corcione M. Heat transfer features of buoyancy-driven nanofluids inside rectangular enclosures differentially heated at the sidewalls. Int J Therm Sci. 2010;49–9:1536–46.

Sahu M, Sarkar J. Steady-state energetic and exergetic performances of single-phase natural circulation loop with hybrid nanofluids. J Heat Transf. 2019;141:082401.

Sheikholeslami M, Shamlooei M. Magnetic source influence on nanofluid flow in porous medium considering shape factor effect. Phys Lett A. 2017;381:3071–8.

Elias MM, Shahrul IM, Mahbubul IM, Saidur R, Rahim NA. Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid. Int J Heat Mass Transf. 2014;70:289–97.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhattad, A., Sarkar, J. Effects of nanoparticle shape and size on the thermohydraulic performance of plate evaporator using hybrid nanofluids. J Therm Anal Calorim 143, 767–779 (2021). https://doi.org/10.1007/s10973-019-09146-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09146-z