Abstract

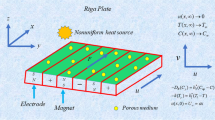

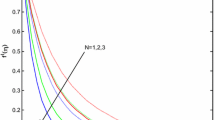

In this paper, a mathematical analysis for three-dimensional Eyring–Powell nanofluid nonlinear thermal radiation with modified heat plus mass fluxes is investigated. To enhance the dynamical and physical study of structure, the slip condition is introduced. A Riga plate is employed for avoiding boundary-layer separation to diminish the friction and pressure drag of submarines. To evaluate the heat transfer, the Cattaneo–Christov heat flux model is implemented via appropriate transformation. A comparison between bvp4c results and shooting technique is made. Graphical and numerical illustrations are presented for prominent parameters.

Similar content being viewed by others

Abbreviations

- u, v, w :

-

Velocity components

- \(\text{Re}_{\text{x}} ,\text{Re}_{\text{y}}\) :

-

Local Reynolds number

- Q :

-

Modified Hartmann number

- Sc:

-

Schmidt number

- \({\text{Nu}}_{\text{x}}\) :

-

Local Nusselt number

- K 1 :

-

Porosity parameter

- \({\text{Nr}}\) :

-

Radiation parameter

- \(\tilde{T}_{\infty }\) :

-

Ambient temperature

- E 1 :

-

Activation energy

- \(f^{\prime } ,g^{\prime }\) :

-

Velocities

- \(\tilde{C}_{\text{f}}\) :

-

Skin friction coefficient

- J 0 :

-

Current density

- \(q_{\text{w}}\) :

-

Wall heat flux

- \(D_{\text{T}}\) :

-

Thermophoretic diffusion coefficient

- x, y, z :

-

Coordinate axes

- \(\Pr\) :

-

Prandtl number

- \(N_{\text{T}}\) :

-

Thermophoresis number

- \({\text{Le}}\) :

-

Lewis number

- \({\text{Sh}}_{\text{x}}\) :

-

Local Sherwood number

- B :

-

Dimensionless parameter

- M :

-

Magnetic parameter

- \(\tilde{T}_{\text{f}}\) :

-

Convective surface temperature

- \(N_{\text{B}}\) :

-

Brownian motion

- \(\tilde{C}_{\infty }\) :

-

Ambient concentration

- \(\delta_{\text{c}}\) :

-

Time relaxation

- \(h_{\text{m}}\) :

-

Wall mass flux

- M 0 :

-

Magnetization magnets

- \(D_{\text{B}}\) :

-

Brownian diffusion coefficient

- β :

-

Stretching parameter

- δ :

-

Heat basis parameter

- σ :

-

Chemical reaction parameter

- γ :

-

Biot number

- λ :

-

Stretching parameter

- α 1 :

-

Width for magnets and electrodes

- δ * :

-

Electric conductivity

- Γ :

-

Material parameter

- \(\varOmega_{\text{E}}\) :

-

Thermal relaxation time

- \(\rho\) :

-

Density

- α :

-

Velocity slip parameter

- ω :

-

Non-dimensional fluid parameter

- β 0 :

-

Magnetic field strength

- ϕ :

-

Concentration distribution

- θ :

-

Temperature distribution

- \(\delta_{\text{t}}\) :

-

Temperature diffusion

- \(\varOmega_{\text{C}}\) :

-

Concentration relaxation time

- \(\tau_{\text{w}}\) :

-

Wall shear stress

References

Rashidi S, Javadi P, Esfahani JA. Second law of thermodynamics analysis for nanofluid turbulent flow inside a solar heater with the ribbed absorber plate. J Therm Anal Calorim. 2019;135(1):551–63.

Shamsabadi H, Rashidi S, Esfahani JA. Entropy generation analysis for nanofluid flow inside a duct equipped with porous baffles. J Therm Anal Calorim. 2019;35(2):1009–19.

Maleki H, Safaei MR, Togun H, Dahari M. Heat transfer and fluid flow of pseudo-plastic nanofluid over a moving permeable plate with viscous dissipation and heat absorption/generation. J Therm Anal Calorim. 2019;135(3):1643–54.

Khan A, Ali HM, Nazir R, Ali R, Munir A, Ahmad B, Ahmad Z. Experimental investigation of enhanced heat transfer of a car radiator using ZnO nanoparticles in H2O–ethylene glycol mixture. J Therm Anal Calorim. 2019;138(5):3007–21.

Szilagyi IM, Santala E, Heikkilä M, Kemell M, Nikitin T, Khryashchev L, Rasanen M, Ritala M, Leskelä M. Thermal study on electrospun polyvinylpyrrolidone/ammonium metatungstate nanofibers: optimising the annealing conditions for obtaining WO3 nanofibers. J Therm Anal Calorim. 2011;105:73–81.

Khan LA, Reza M, Mir NA, Ellahi R. Effects of different shapes of nanoparticles on peristaltic flow of MHD nanofluids filled in an asymmetric channel. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08348-9.

Alamri SZ, Ellahi R, Shehzad N, Zeeshan A. Convective radiative plane Poiseuille flow of nanofluid through porous medium with slip: an application of Stefan blowing. J Mol Liq. 2019;273:292–304.

Hassan M, Marin M, Ellahi R, Alamri SZ. Exploration of convective heat transfer and flow characteristics synthesis by Cu–Ag/water hybrid-nanofluids. Heat Transf Res. 2018;49(18):1837–48.

Laein RP, Rashidi S, Esfahani JA. Experimental investigation of nanofluid free convection over the vertical and horizontal flat plates with uniform heat flux by PIV. Adv Powder Technol. 2016;27:312–22.

Ellahi R, Alamri SZ, Basit A, Majeed A. Effects of MHD and slip on heat transfer boundary layer flow over a moving plate based on specific entropy generation. J Taibah Univ Sci. 2018;12(4):476–82.

Bovand M, Rashidi S, Esfahani JA. Optimum interaction between magnetohydrodynamics and nanofluid for thermal and drag management. J Thermophys Heat Transf. 2016;31:218–29.

Maleki H, Alsarraf J, Moghanizadeh A, Hajabdollahi H, Safaei MR. Heat transfer and nanofluid flow over a porous plate with radiation and slip boundary conditions. J Central South Univ. 2019;26(5):1099–115.

Nasiri H, Jamalabadi MYA, Sadeghi R, Safaei MR, Nguyen TK, Shadloo MS. A smoothed particle hydrodynamics approach for numerical simulation of nanofluid flows. J Therm Anal Calorim. 2019;135(3):1733–41.

Kamalgharibi M, Hormozi F, Zamzamian SAH, Sarafraz MM. Experimental studies on the stability of CuO nanoparticles dispersed in different base fluids: influence of stirring, sonication and surface active agents. Heat Mass Transf. 2016;52(1):55–62.

Salari E, Peyghambarzadeh SM, Sarafraz MM, Hormozi F. Boiling thermal performance of TiO2 aqueous nanofluids as a coolant on a disc copper block. Periodica Polytech Chem Eng. 2016;60(2):106–12.

Sarafraz MM, Hormozi F. Convective boiling and particulate fouling of stabilized CuO–ethylene glycol nanofluids inside the annular heat exchanger. Int Commun Heat Mass Transf. 2014;53:116–23.

Sarafraz MM, Hormozi F. Pool boiling heat transfer to dilute copper oxide aqueous nanofluids. Int J Therm Sci. 2015;90:224–37.

Majeed A, Zeeshan A, Bhatti MM, Ellahi R. Heat transfer in magnetite (Fe3O4) nanoparticles suspended with conventional fluids: refrigerant-134a (C2H2F4), kerosene (C10H22) and water (H2O) under the impact of dipole. Heat Transf Res. 2020;51(3):217–32.

Hassan A, Wahab A, Qasim MA, Janjua MM, Ali MA, Ali HM, Jadoon TR, Ali E, Raza A, Javaid N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew Energy. 2020;145:282–93.

Ambreen T, Saleem A, Ali HM, Shehzad SA, Park CW. Performance analysis of hybrid nanofluid in a heat sink equipped with sharp and streamlined micro pin-fins. Powder Technol. 2019;355:552–63.

Choi SUS, Eastman JA. Enhancing thermal conductivity of fluid with nanoparticles. In: Conference: 1995 international mechanical engineering congress and exhibition, San Francisco, CA, 1995, p. 12–17.

Boungiorno J, Hu LW, Kim SJ, Hannink R, Truong B, Forrest E. Nanofluids for enhanced economics and safety of nuclear reactors: an evaluation of potential features, issues, and research gaps. Nucl Technol. 2008;162:80–91.

Powell RE, Eyring H. Mechanisms for the relaxation theory of viscosity. Nature. 1944;154:427–8.

Patel M, Timol MG. Numerical treatment of Powell–Eyring fluid flow using method of satisfaction of asymptotic boundary conditions (MSABC). Appl Numer Math. 2009;59:84–92.

Hayat T, Abbas Z, Qasim M, Obidet S. Steady flow of an Eyring Powell fluid over a moving surface with convective boundary condition. Int J Heat Mass Transf. 2012;8:17–22.

Akbar NS, Ebraid A, Khan ZH. Numerical analysis of magnetic field effects on Eyring–Powell fluid flow towards a stretching sheet. J Magn Magn Mater. 2015;382:355–8.

Hayat T, Hussain Z, Farooq M, Alsaedi A. Magnetohydrodynamic flow of Powell–Eyring fluid by a stretching cylinder with Newtonian heating. Therm Sci. 2018;22:371–82.

Ellahi R. The effects of MHD and temperature dependent viscosity on the flow of non-Newtonian nanofluid in a pipe: analytical solutions. Appl Math Model. 2013;37(3):1451–7.

Alamri SZ, Khan AA, Azeez M, Ellahi R. Effects of mass transfer on MHD second grade fluid towards stretching cylinder: a novel perspective of Cattaneo–Christov heat flux model. Phys Lett A. 2019;383:276–81.

Ellahi R, Zeeshan A, Hussain F, Abbas T. Thermally charged MHD bi-phase flow coatings with non-Newtonian nanofluid and Hafnium particles through slippery walls. Coatings. 2019;9:300.

Ellahi R, Zeeshan A, Hussain F, Abbas T. Two-phase Couette flow of Couple stress fluid with temperature dependent viscosity thermally affected by magnetized moving surface. Symmetry. 2019;11(5):647.

Ellahi R, Hussain F, Ishtiaq F, Hussain A. Peristaltic transport of Jeffrey fluid in a rectangular duct through a porous medium under the effect of partial slip: an approach to upgrade industrial sieves/filters. Pramana. 2019;93:34.

Khan AA, Bukhari SR, Marin M, Ellahi R. Effects of chemical reaction on third grade magnetohydrodynamics fluid flow under the influence of heat and mass transfer with variable reactive index. Heat Transf Res. 2019;50(11):1061–80.

Ellahi R, Sait SM, Shehzad N, Mobin N. Numerical simulation and mathematical modeling of electro-osmotic Couette–Poiseuille flow of MHD power-law nanofluid with entropy generation. Symmetry. 2019;11:1038.

Maleki H, Safaei MR, Alrashed AAAA, Kasaeian A. Flow and heat transfer in non-Newtonian nanofluids over porous surfaces. J Therm Anal Calorim. 2019;135:1655–66.

Eldabe NT, Hassan AA, Mohamed MA. Effect of couple stresses on the MHD of a non-Newtonian unsteady flow between two parallel porous plates. Zeitschrift für Naturforschung A. 2003;58:204–10.

Malik MY, Bilal S, Bibi M, Ali U. Logarithmic and parabolic curve fitting analysis of dual stratified stagnation point MHD mixed convection flow of Eyring–Powell fluid induced by an inclined cylindrical stretching surface. Results Phys. 2017;7:544–52.

Islam S, Shah A, Zhou CY, Ali I. Homotopy perturbation analysis of slider bearing with Powell–Eyring fluid. Z Angew Math Phys. 2009;60:1178.

Akbar NS, Nadeem S. Characteristics of heating scheme and mass transfer on the peristaltic flow for an Eyring–Powell fluid in an endoscope. Int J Heat Mass Transf. 2012;55:375–83.

Sirohi V, Timol MG, Kalthia NL. Powell–Eyring model flow near an accelerated plate. Fluid Dyn Res. 1987;2(3):193–204.

Nadeem S, Akbar NS, Ali M. Endoscopic effects on the peristaltic flow of an Eyring–Powell fluid. Meccanica. 2012;47(3):687–97.

Jayachandra Babu M, Sandeep N, Raju CS. Heat and mass transfer in MHD Eyring–Powell nanofluid flow due to cone in porous medium. Int J Eng Res Afr. 2016;19:57–74.

Yoon HK, Ghajar AJ. A note on the Powell–Eyring fluid model. Int Commun Heat Mass Transf. 1987;14(4):381–90.

Agbaje TM, Mondal S, Motsa SS, Sibanda P. A numerical study of unsteady non-Newtonian Powell–Eyring nanofluid flow over a shrinking sheet with heat generation and thermal radiation. Alex Eng J. 2017;56(1):81–91.

Gailitis A, Lielausis O. On the possibility to reduce the hydrodynamic drag of a plate in an electrolyte. Appl Magnetohydrodyn Rep Phys Inst Riga. 1961;12:143–6.

Ahmad R, Mustafa M, Turkyilmazoglu M. Buoyancy effects on nanofluid flow past a convectively heated vertical Riga-plate: a numerical study. Int J Heat Mass Transf. 2017;111:827–35.

Iqbal Z, Mehmood Z, Azhar E, Maraj EN. Numerical investigation of nanofluidic transport of gyrotactic microorganisms submerged in water towards Riga plate. J Mol Liq. 2017;234:296–308.

Khan NA, Aziz S, Khan NA. MHD flow of Powell–Eyring fluid over a rotating disk. J Taiwan Inst Chem Eng. 2014;45(6):2859–67.

Makinde OD, Aziz A. Boundary layer flow of a nanofluid past a stretching sheet with a convective boundary condition. Int J Therm Sci. 2011;50(7):1326–32.

Goodarzi M, Safaei MR, Vafai K, Ahmadi G, Dahari M, Kazi SN, Jomhari N. Investigation of nanofluid mixed convection in a shallow cavity using a two-phase mixture model. Int J Therm Sci. 2014;75:204–20.

Riaz A, Ellahi R, Bhatti MM, Marin M. Study of heat and mass transfer in the Eyring–Powell model of fluid propagating peristaltically through a rectangular complaint channel. Heat Transf Res. 2019;50(16):1539–60.

Gireesha BJ, Gorla RS, Mahanthesh B. Effect of suspended nanoparticles on three-dimensional MHD flow, heat and mass transfer of radiating Eyring–Powell fluid over a stretching sheet. J Nanofluids. 2015;4(4):474–84.

Hayat T, Muhammad T, Shehzad SA, Alsaedi A. Similarity solution to three dimensional boundary layer flow of second grade nanofluid past a stretching surface with thermal radiation and heat source/sink. AIP Adv. 2015;5(1):017107.

Hayat T, Muhammad T, Shehzad SA, Alsaedi A. Three-dimensional boundary layer flow of Maxwell nanofluid. J Mol Liq. 2017;229:495–500.

Hedayati F, Malvandi A, Kaffash MH, Ganji DD. Fully developed forced convection of alumina/water nanofluid inside microchannels with asymmetric heating. Powder Technol. 2015;269:520–31.

Fukui S, Kaneko R. A database for interpolation of Poiseuille flow rates for high Knudsen number lubrication problems. J Tribol. 1990;112(1):78–83.

Maxwell JC. On stresses in rarified gases arising from inequalities of temperature. Philos Trans R Soc Lond. 1879;170:231–56.

Mitsuya Y. Modified Reynolds equation for ultra-thin film gas lubrication using 1.5-order slip-flow model and considering surface accommodation coefficient. J Tribol. 1993;115(2):289–94.

Hsia YT, Domoto GA, Hsia YT, Domoto GA. An experimental investigation of molecular rarefaction effects in gas lubricated bearings at ultra-low clearances. J Tribol. 1983;105:120–30.

Maleque K. Effects of exothermic/endothermic chemical reactions with Arrhenius activation energy on MHD free convection and mass transfer flow in presence of thermal radiation. J Thermodyn. 2013;2013:692516.

Zhang J, Li Y, Xie J. Numerical simulation of fractional control system using Chebyshev polynomials. Math Probl Eng. 2018;2018:4270764.

Shafique Z, Mustafa M, Mushtaq A. Boundary layer flow of Maxwell fluid in rotating frame with binary chemical reaction and activation energy. Results Phys. 2016;6(1):627–33.

Hemeda AA, Eladdad EE. New iterative methods for solving Fokker–Planck equation. Math Probl Eng. 2018;2018:6462174.

Asadollahi A, Esmaeeli A. Simulation of condensation and liquid break-up on a micro-object with upper and lower movable walls using Lattice Boltzmann method. Physica A. 2018;498:33–49.

Rashidi S, Akbarzadeh M, Karimi N, Masoodi R. Combined effects of nanofluid and transverse twisted-baffles on the flow structures heat transfer and irreversibilities inside a square duct—a numerical study. Appl Therm Eng. 2018;130:135–48.

Ellahi R, Sait SM, Shehzad N, Ayaz Z. A hybrid investigation on numerical and analytical solutions of electro-magnetohydrodynamics flow of nanofluid through porous media with entropy generation. Int J Numer Meth Heat Fluid Flow. 2020;30(2):834–54.

Nikkhah V, Sarafraz MM, Hormozi F, Peyghambarzadeh SM. Particulate fouling of CuO–water nanofluid at isothermal diffusive condition inside the conventional heat exchanger-experimental and modeling. Exp Therm Fluid Sci. 2015;60:83–95.

Khan JA, Mustafa M, Hayat T, Alsaedi A. Numerical study of Cattaneo–Christov heat flux model for viscoelastic flow due to an exponentially stretching surface. PLoS ONE. 2015;10:0137363.

Nadeem S, Muhammad N. Impact of stratification and Cattaneo–Christov heat flux in the flow saturated with porous medium. J Mol Liq. 2016;224:423–30.

Hayat T, Zubair M, Waqas M, Alsaedi A, Ayub M. On doubly stratified chemically reactive flow of Powell–Eyring liquid subject to non-Fourier heat flux theory. Results Phys. 2017;7:99–106.

Salahuddin T, Malik MY, Hussain A, Bilal S, Awais M. MHD flow of Cattanneo–Christov heat flux model for Williamson fluid over a stretching sheet with variable thickness: using numerical approach. J Magn Magn Mater. 2016;401:991–7.

Hayat T, Ali Shehzad S, Qasim M, Asghar S. Three-dimensional stretched flow via convective boundary condition and heat generation/absorption. Int J Numer Methods Heat Fluid Flow. 2014;24(2):342–58.

Hayat T, Muhammad T, Alsaedi A, Ahmad B. Three-dimensional flow of nanofluid with Cattaneo–Christov double diffusion. Results Phys. 2016;6:897–903.

Umar M, Akhtar R, Sabir Z, Wahab HA, Zhiyu Z, Imran A, Shoaib M, Raja MAZ. Numerical treatment for the three-dimensional Eyring–Powell fluid flow over a stretching sheet with velocity slip and activation energy. Adv Math Phys. 2019;2019:9860471.

Freidoonimehr N, Rahimi AB. Brownian motion effect on heat transfer of a three-dimensional nanofluid flow over a stretched sheet with velocity slip. J Therm Anal Calorim. 2019;135(1):207–22.

Wang CY. The three dimensional flow due to a stretching flat surface. Phys Fluids. 1984;27(8):1915.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muhammad, T., Waqas, H., Khan, S.A. et al. Significance of nonlinear thermal radiation in 3D Eyring–Powell nanofluid flow with Arrhenius activation energy. J Therm Anal Calorim 143, 929–944 (2021). https://doi.org/10.1007/s10973-020-09459-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09459-4