Abstract

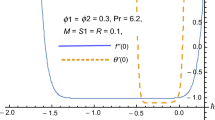

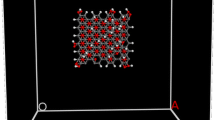

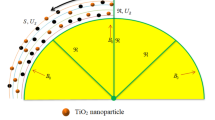

The present investigation concentrates on the hydrothermal features of both hybrid nanofluid and usual nanofluid flow over a slippery permeable bent structure. The surface has also been considered to be coiled inside the circular section of radius R. Ferrous and graphene nanoparticles along with the host fluid water are taken to simulate the flow. The existence of heat sink/source and thermal radiation are incorporated within the system. Resulting equations are translated into its non-dimensional form using similarity renovation and solved by the RK-4 method. The consequence of pertinent factors on the flow profile is explored through graphs and tables. Streamlines and isotherms for both hybrid nanofluid and usual nanofluid are depicted to show the hydrothermal variations. The result communicates that temperature is reduced for curvature factor, whereas velocity is found to be accelerated. Heat transfer is intensified for thermal Biot number, and the rate of increment is higher for hybrid nanosuspension. Velocity and temperature are intensified for enhanced nanoparticle concentration. The heat transport process is decreased for the heat source parameter, but the reduction rate is comparatively slower for hybrid nanofluid.

Similar content being viewed by others

Abbreviations

- \(\left( {u,v} \right)\) :

-

Velocity components (m s−1)

- \(r,s \,\) :

-

Spatial coordinates (m)

- \(a\) :

-

Stretching constant (s−1)

- \(U_{\text{w}}\) :

-

Stretching velocity (m s−1)

- \(a\) :

-

Stretching rate (s−1)

- \(R\) :

-

Radius of curvature (m)

- \(T_{{\rm w}}\) :

-

Temperature of the surface (K)

- \(T_{\infty }\) :

-

Temperature away from surface (K)

- \(T\) :

-

Hybrid nanofluid temperature (K)

- \(\rho\) :

-

Density (kg m−3)

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s−1)

- \(\kappa\) :

-

Thermal conductivity (W m−1 K−1)

- \(\rho C_{{\rm p}}\) :

-

Heat capacitance (J m−3 K−1)

- \(\sigma\) :

-

Electrical conductivity (Ω−1 m−1)

- \(B_{0}\) :

-

Magnetic field (Ω1/2 m−1 s−1/2 kg1/2)

- \(q_{{\rm r}}\) :

-

Radiative heat flux (kg s−3)

- \(\sigma^{*}\) :

-

Stefan Boltzmann constant (W m−2 K−4)

- \(k^{*}\) :

-

Mean absorption coefficient (m−1)

- \(L\) :

-

Velocity slip factor (m)

- \(v_{{\rm w}}\) :

-

Suction/injection velocity (m s−1)

- \(h\) :

-

Convective heat transport coefficient (W m−2 K−1)

- \(\phi\) :

-

Nanoparticle volume fraction

- \(Q\) :

-

Heat source or sink

- \(K = \sqrt {\frac{a}{{\nu_{{\rm f}} }}} R\) :

-

Curvature parameter

- \(L_{{\rm slip}} = L\sqrt {\frac{a}{{\nu_{{\rm f}} }}}\) :

-

Velocity slip parameter

- \(\Pr = \frac{{\mu_{{\rm f}} \left( {\rho C_{{\rm p}} } \right)_{{\rm f}} }}{{\rho_{{\rm f}} \kappa_{{\rm f}} }}\) :

-

Prandtl number

- \(M = \frac{{\sigma_{{\rm f}} B_{0}^{2} }}{{a\rho_{{\rm f}} }}\) :

-

Magnetic parameter

- \(S = - \frac{{v_{{\rm w}} }}{{\sqrt {a\nu_{{\rm f}} } }}\) :

-

Suction/injection parameter

- \({\text{Bi}} = \frac{{h_{{\rm f}} }}{{\kappa_{{\rm f}} }}\sqrt {\frac{{\nu_{{\rm f}} }}{a}}\) :

-

Biot number

- \(N = \frac{{4\sigma^{*} T^{3}_{\infty } }}{{3k^{*} \kappa_{{\rm f}} }}\) :

-

Radiation parameter

- \(\theta_{{\rm w}} = \frac{{T_{{\rm w}} }}{{T_{\infty } }}\) :

-

Temperature ratio parameter

- \(\lambda = \frac{Q}{{a\left( {\rho c_{{\rm p}} } \right)_{{\rm f}} }}\) :

-

Heat source/sink parameter

- Nu:

-

Nusselt number

- \(C_{{\rm f}}\) :

-

Skin friction

- \({\text{Nu}}_{{\rm r}}\) :

-

Reduced Nusselt number

- \(C_{{\rm fr}}\) :

-

Reduced skin friction

- \(\text{Re}_{{\rm s}} = \frac{{as^{2} }}{{\nu_{{\rm f}} }}\) :

-

Local Reynold’s number

- \({\text{f}}\) :

-

Base fluid

- \({\text{nf}}\) :

-

Nanofluid

- \({\text{hnf}}\) :

-

Hybrid nanofluid

- \(1, \, 2\) :

-

First and second nanoparticle, respectively

References

Choi SUS. Enhancing thermal conductivity of fluids with nanoparticles. In: Siginer DA, Wang HP, editors. Developments and applications of non-Newtonian flows, vol. 66. New York: ASME; 1995.

Sajid MU, Ali HM. Recent advances in application of nanofluids in heat transfer devices: a critical review. Renew Sustain Energy Rev. 2019;103:556–92.

Khan MS, Abid M, Ali HM, Amber KP, Bashir MA, Javed S. Comparative performance assessment of solar dish assisted s-CO2 Brayton cycle using nanofluids. Appl Therm Eng. 2019;148:295–306.

Esfe MH, Afrand M. A review on fuel cell types and the application of nanofluid in their cooling. J Therm Anal Calorim. 2020;140:1633–54.

Sheikholeslami M. New computational approach for exergy and entropy analysis of nanofluid under the impact of Lorentz force through a porous media. J Clean Prod. 2019;344:319–33.

Sheikholeslami M, Rezaeianjouybari B, Darzi M, Shafee A, Li Z, Nguyen TK. Application of nano-refrigerant for boiling heat transfer enhancement employing an experimental study. Int J Heat Mass Transf. 2019;141:974–80.

Sadeghi A, Amini Y, Saidi MH, Chakraborty S. Numerical modeling of surface reaction kinetics in electrokinetically actuated microfluidic devices. Anal Chim Acta. 2014;838:64–75.

Sadeghi A, Amini Y, Saidi MH, Yavari H. Shear-rate-dependent rheology effects on mass transport and surface reactions in biomicrofluidic devices. AIChE J. 2015;61:1912–24.

Abdollahi P, Sabet JK, Moosavian MA, Amini Y. Microfluidic solvent extraction of calcium: modeling and optimization of the process variables. Sep Purif Technol. 2020;231:115875.

Marsousi S, Sabet JK, Moosavian MA, Amini Y. Liquid–liquid extraction of calcium using ionic liquids in spiral microfluidics. Chem Eng J. 2019;356:492–505.

Sheikholeslami M, Jafaryar M, Shafee A, Babazadeh H. Acceleration of discharge process of clean energy storage unit with insertion of porous foam considering nanoparticle enhanced paraffin. J Clean Prod. 2020;261:121206.

Jahromi PF, Sabet JK, Amini Y. Ion-pair extraction-reaction of calcium using Y-shaped microfluidic junctions: an optimized separation approach. Chem Eng J. 2018;334:2603–15.

Sheikholeslami M, Haq R, Shafee A, Li Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int J Heat Mass Transf. 2019;130:1322–42.

Mabood F, Khan WA, Makinde OD. Hydromagnetic flow of a variable viscosity nanofluid in a rotating permeable channel with Hall effects. J Eng Thermophys. 2017;26:553–66.

Mabood F, Nayak MK, Chamkha AJ. Heat transfer on the cross flow of micropolar fluids over a thin needle moving in a parallel stream influenced by binary chemical reaction and Arrhenius activation energy. Eur Phys J. 2019;134(9):427.

Khan NS, Zuhra S, Shah Z, Bonyah E, Khan W, Islam S. Slip flow of Eyring–Powell nanoliquid film containing graphene nanoparticles. AIP Adv. 2018;8:115302.

Aly EH. Dual exact solutions of graphene–water nanofluid flow over stretching/shrinking sheet with suction/injection and heat source/sink: critical values and regions with stability. Powder Technol. 2019;342:528–44.

Ullah I, Waqas M, Hayat T, Alsaedi A, Khan MI. Thermally radiated squeezed flow of magneto-nanofluid between two parallel disks with chemical reaction. J Therm Anal Calorim. 2019;135:1021–30.

Acharya N, Das K, Kundu PK. Effects of aggregation kinetics on nanoscale colloidal solution inside a rotating channel: a thermal framework. J Therm Anal Calorim. 2019;138(1):461–77.

Animasaun IL, Koriko OK, Adegbie KS, Babatunde HA, Ibraheem RO, Sandeep N, Mahanthesh B. Comparative analysis between 36 nm and 47 nm alumina–water nanofluid flows in the presence of Hall effect. J Therm Anal Calorim. 2019;135(2):873–86.

Sajid MU, Ali HM. Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf. 2018;126:211–34.

Kaska SA, Khalefa RA, Hussein AM. Hybrid nanofluid to enhance heat transfer under turbulent flow in a flat tube. Case Stud Therm Eng. 2019;13:100398.

Shah TR, Ali HM. Applications of hybrid nanofluids in solar energy, practical limitations and challenges: a critical review. Sol Energy. 2019;183:173–203.

Huminic G, Huminic A. Hybrid nanofluids for heat transfer applications—a state-of-the-art review. Int J Heat Mass Transf. 2018;125:82–103.

Esfe MH, Esfandeh S, Rejvani M. Modeling of thermal conductivity of MWCNT-SiO2 (30:70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications: an experimental based study. J Therm Anal Calorim. 2018;131:1437–47.

Derakhshan R, Shojaei A, Hosseinzadeh Kh, Nimafar M, Ganji DD. Hydrothermal analysis of magneto hydrodynamic nanofluid flow between two parallel by AGM. Case Stud Therm Eng. 2019;14:100439.

Pandey AK, Kumar MM. Effect of viscous dissipation and suction/injection on MHD nanofluid flow over a wedge with porous medium and slip. Alex Eng J. 2016;55:3115–23.

Zeeshan A, Ellahi R, Mabood F, Hussain F. Numerical study on bi-phase coupled stress fluid in the presence of Hafnium and metallic nanoparticles over an inclined plane. Int J Numer Methods Heat Fluid Flow. 2019;29:2854–69.

Acharya N, Das K, Kundu PK. Rotating flow of carbon nanotube over a stretching surface in the presence of magnetic field: a comparative study. Appl Nanosci. 2018;8(3):369–78.

Ahmad R, Mustafa M, Hayat T, Alsaedi A. A numerical study of MHD nanofluid flow and heat transfer past a bidirectional exponentially stretching sheet. J Magn Magn Mater. 2016;407:69–74.

Manjunatha S, Kuttan BA, Jayanthi S, Chamkha AJ, Gireesha BJ. Heat transfer enhancement in the boundary layer flow of hybrid nanofluids due to variable viscosity and natural convection. Heliyon. 2019;5(4):e01469.

Hayat T, Nadeem S. Heat transfer enhancement with Ag–CuO/water hybrid nanofluid. Results Phys. 2017;7:2317–24.

Yousefi M, Dinarvand S, Yazdi ME, Pop I. Stagnation-point flow of an aqueous titania-copper hybrid nanofluid toward a wavy cylinder. Int J Numer Methods Heat Fluid Flow. 2018;28(7):1716–35.

Afridi MI, Tlili I, Goodarzi M, Osman M, Khan NA. Irreversibility analysis of hybrid nanofluid flow over a thin needle with effects of energy dissipation. Symmetry. 2019;11(5):663.

Nadeem S, Hayat T, Khan AU. Numerical study on 3D rotating hybrid SWCNT/MWCNT flow over a convectively heated stretching surface with heat generation/absorption. Phys Scr. 2019;94:075202.

Dinarvand S, Rostami MN, Pop I. A novel hybridity model for TiO2–CuO/water hybrid nanofluid flow over a static/moving wedge or corner. Sci Rep. 2019;9:16290.

Acharya N, Bag R, Kundu PK. Influence of Hall current on radiative nanofluid flow over a spinning disk: a hybrid approach. Phys E Low Dimens Syst Nanostruct. 2019;111:103–12.

Devi SSU, Devi SPA. Numerical investigation of three-dimensional hybrid Cu Al2O3/water nanofluid flow over a stretching sheet with effecting Lorentz force subject to Newtonian heating. Can J Phys. 2016;94(5):490–6.

Acharya N, Bag R, Kundu PK. On the impact of nonlinear thermal radiation on magnetized hybrid condensed nanofluid flow over a permeable texture. Appl Nanosci. 2019. https://doi.org/10.1007/s13204-019-01224-w.

Acharya N, Maity S, Kundu PK. Influence of inclined magnetic field on the flow of condensed nanomaterial over a slippery surface: the hybrid visualization. Appl Nanosci. 2020;10:633–47.

Ali A, Saleem S, Mumraiz S, Saleem A, Awais M, Marwat DNK. Investigation on TiO2–Cu/H2O hybrid nanofluid with slip conditions in MHD peristaltic flow of Jeffrey material. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09648-1.

Hassan M, Marin M, Ellahi R, Alamri SZ. Exploration of convective heat transfer and flow characteristics synthesis by Cu–Ag/water hybrid nanofluids. Heat Transf Res. 2018;49(18):1837–48.

Sajid M, Ali N, Javed T, Abbas Z. Stretching a curved surface in a viscous fluid. Chin Phys Lett. 2010;27:024703.

Sanni KM, Asghar S, Jalil M, Okechi NF. Flow of viscous fluid along a nonlinearly stretching curved surface. Results Phys. 2017;7:1–4.

Shaiq S, Maraj EN. Role of the induced magnetic field on dispersed CNTs in propylene glycol transportation toward a curved surface. Arab J Sci Eng. 2019;44:7515–28.

Imtiaz M, Hayat T, Alsaedi A. Convective flow of ferrofluid due to a curved stretching surface with homogeneous heterogeneous reactions. Powder Technol. 2017;310:154–62.

Afridi MI, Alkanhal TA, Qasim M, Tlili I. Entropy generation in Cu–Al2O3–H2O hybrid nanofluid flow over a curved surface with thermal dissipation. Entropy. 2019;21:941.

Saba F, Ahmed N, Hussain S, Khan U, Mohyud-Din ST, Darus M. Thermal analysis of nanofluid flow over a curved stretching surface suspended by carbon nanotubes with internal heat generation. Appl Sci. 2018;8:395.

Acharya N. Active–passive controls of liquid di-hydrogen mono-oxide based nanofluidic transport over a bended surface. Int J Hydrogen Energy. 2019;44(50):27600–14.

Acharya N, Bag R, Kundu PK. On the mixed convective carbon nanotube flow over a convectively heated curved surface. Heat Transf. 2020. https://doi.org/10.1002/htj.21687.

Chamkha AJ, Dogonchi AS, Ganji DD. Magneto-hydrodynamic flow and heat transfer of a hybrid nanofluid in a rotating system among two surfaces in the presence of thermal radiation and Joule heating. AIP Adv. 2019;9:025103.

Mehmood Z, Iqbal Z, Azhar E, Maraj EN. Nanofluidic transport over a curved surface with viscous dissipation and convective mass flux. Z Naturforsch. 2016;72(3):223–9.

Abbas Z, Naveed M, Sajid M. Heat transfer analysis for stretching flow over a curved surface with magnetic field. J Eng Thermophys. 2013;22(4):337–45.

Imtiaz M, Mabood F, Hayat T, Alsaedi A. Homogeneous–heterogeneous reactions in MHD radiative flow of second grade fluid due to a curved stretching surface. Int J Heat Mass Transf. 2019;145:118781.

Ullah I, Hayat T, Alsaedi A, Asghar S. Dissipative flow of hybrid nanoliquid (H2O–aluminum alloy nanoparticles) with thermal radiation. Phys Scr. 2019;94(12):125708.

Makinde OD, Mabood F, Ibrahim SM. Chemically reacting on MHD boundary layer flow of nanofluids over a nonlinear stretching sheet with heat source/sink and thermal radiation. Therm Sci. 2018;22:495–506.

AnanthaKumar K, Sandeep N, Sugunamma V, et al. Effect of irregular heat source/sink on the radiative thin film flow of MHD hybrid ferrofluid. J Therm Anal Calorim. 2020;139:2145–53.

Acharya N. On the flow patterns and thermal behaviour of hybrid nanofluid flow inside a microchannel in presence of radiative solar energy. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09111-w.

Takabi B, Gheitaghy AM, Tazraei P. Hybrid water-based suspension of Al2O3 and Cu nanoparticles on laminar convection effectiveness. J Thermophys Heat Transf. 2016;30(3):523–32.

Oztop HF, Abu-Nada E. Numerical study of natural convection in partially heated rectangular enclosures with nanofluids. Int J Heat Fluid Flow. 2008;29:1326–36.

Maxwell J. A treatise on electricity and magnetism. 2nd ed. Cambridge: Oxford University Press; 1904.

Acknowledgements

The authors wish to express their cordial thanks to the respected Editor in chief and honourable reviewers for their valuable suggestions and comments to improve the presentation of this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Acharya, N., Mabood, F. On the hydrothermal features of radiative Fe3O4–graphene hybrid nanofluid flow over a slippery bended surface with heat source/sink. J Therm Anal Calorim 143, 1273–1289 (2021). https://doi.org/10.1007/s10973-020-09850-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09850-1