Abstract

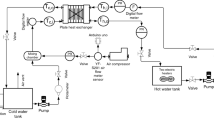

The main aim of this study is to evaluate thermal performance and exergy analysis of a shell-and-tube heat exchanger with a new technique called air bubble injection. The study has been carried out with different parameters such as flow rate, fluid inlet temperature, and different air injection techniques. The air has been injected at different locations such as the inlet of pipe, throughout the pipe, and in the outer pipe of the heat exchanger. Based on the results, the performance of the heat exchanger enhances with an increase in the flow rate and the fluid inlet temperature. The exergy loss and dimensionless exergy loss increase with a rise in the flow rate. The maximum and dimensionless exergy losses are obtained at a maximum flow rate of 3.5 l min−1. With the air bubble injection in the heat exchanger, it has been observed that the temperature difference increases, which leads to an increase in the exergy loss. The injecting air bubbles throughout the tube section shows that minimum dimensionless exergy is 27.49% concerning no air injection.

Similar content being viewed by others

Abbreviations

- A :

-

Tube area, (m2)

- Cp:

-

Specific heat, (J kg−1)

- H :

-

Heat transfer coefficient (W m−2 K−1)

- m :

-

Mass flow rate, (kg s−1)

- Q :

-

Heat transfer rate, (W)

- T :

-

Temperature, (°C)

- U :

-

Overall heat transfer coefficient, (W m−2 K−1)

- Avg:

-

Average

- c:

-

Cold fluid

- h:

-

Hot fluid

- i:

-

Inlet

- m:

-

Mean

- o:

-

Outlet

- w:

-

Wall

References

Maddah H, Ghazvini M, Ahmadi MH. Predicting the efficiency of CuO/water nanofluid in heat pipe heat exchanger using neural network. Int Commun Heat Mass Transf. 2019;104:33–40.

Ahmadi MH, Ghazvini M, Maddah H, Kahani M, Pourfarhang S, Pourfarhang A, et al. Prediction of the pressure drop for CuO/(ethylene glycol–water) nanofluid flows in the car radiator by means of Artificial Neural Networks analysis integrated with genetic algorithm. Phys A Stat Mech its Appl. 2020;124008.

Aghayari R, Maddah H, Pourkiaei SM, Ahmadi MH, Chen L, Ghazvini M. Theoretical and experimental studies of heat transfer in a double-pipe heat exchanger equipped with twisted tape and nanofluid. Eur Phys J Plus. 2020. https://doi.org/10.1140/epjp/s13360-020-00252-8.

Ahmadlouydarab M, Ebadolahzadeh M, Muhammad H. Effects of utilizing nanofluid as working fluid in a lab-scale designed FPSC to improve thermal absorption and efficiency. Physica A. 2020;540:123109. https://doi.org/10.1016/j.physa.2019.123109.

Muneeshwaran M, Sajjad U, Ahmed T, Amer M, Wang C. Performance improvement of photovoltaic modules via temperature homogeneity improvement. 2020;203.

Ali HM. Recent advancements in PV cooling and efficiency enhancement integrating phase change materials based systems – A comprehensive review. Sol Energy. 2020;197:163–98. https://doi.org/10.1016/j.solener.2019.11.075.

Tariq SL, Ali HM, Akram MA, Mansoor M, Ahmadlouydarab M. Nanoparticles enhanced phase change materials (NePCMs) -A recent review. Appl Therm Eng. 2020;176:115305. https://doi.org/10.1016/j.applthermaleng.2020.115305.

Abbas F, Raza T, Babar H, Mansoor M, Sajjad U, Amer M. Nano fluid : potential evaluation in automotive radiator. 2020;297.

Ghazvini M, Maddah H, Peymanfar R, Ahmadi MH, Kumar R. Experimental evaluation and artificial neural network modeling of thermal conductivity of water based nanofluid containing magnetic copper nanoparticles. Phys A Stat Mech Appl; 2020;124127.

Ahmadi MH, Baghban A, Ghazvini M, Hadipoor M, Ghasempour R, Nazemzadegan MR. An insight into the prediction of TiO2/water nanofluid viscosity through intelligence schemes. J Therm Anal Calorim. 2019;139:2381–94.

Ahmadi MH, Tatar A, Seifaddini P, Ghazvini M, Ghasempour R, Sheremet MA. Thermal conductivity and dynamic viscosity modeling of Fe2O3/water nanofluid by applying various connectionist approaches. Numer Heat Transf A Appl. 2018;74:1301–22.

Ahmadi MH, Ghazvini M, Maddah H, Kahani M, Pourfarhang S, Pourfarhang A, et al. Prediction of the pressure drop for CuO/(Ethylene glycol–water) nanofluid flows in the car radiator by means of Artificial Neural Networks analysis integrated with genetic algorithm. Phys A Stat Mech Appl. 2020;546:124008.

Ahmadi MH, Baghban A, Sadeghzadeh M, Hadipoor M, Ghazvini M. Evolving connectionist approaches to compute thermal conductivity of TiO2/water nanofluid. Phys A Stat Mech Appl. 2019

Abbasian Arani AA, Amani J. Experimental investigation of diameter effect on heat transfer performance and pressure drop of TiO2-water nanofluid. Exp Therm Fluid Sci. 2013;44:520–33.

Heyhat MM, Kowsary F, Rashidi AM, Alem Varzane Esfehani S, Amrollahi A. Experimental investigation of turbulent flow and convective heat transfer characteristics of alumina water nanofluids in fully developed flow regime. Int Commun Heat Mass Transf. 2012;39:1272–8.

Singh G, Gangacharyulu D, Bulasara VK. Experimental investigation of the effect of heat transfer and pressure drop on performance of a flat tube by using water-based Al < inf > 2</inf > O<inf > 3</inf > nanofluids. Int J Energy Clean Environ. 2018;19:1–17.

Sokhal GS, Gangacharyulu D, Bulasara VK. Heat transfer and pressure drop performance of alumina–water nanofluid in a flat vertical tube of a radiator. Chem Eng Commun. 2018;205:257–68.

Arabia S. In tube convection heat transfer enhancement : SiO2 aqua based nano fluids. 2020;308.

Lu J, Fernández A, Tryggvason G. The effect of bubbles on the wall drag in a turbulent channel flow. Phys Fluids. 2005;17:1–12.

Mattson M, Mahesh K. Simulation of bubble migration in a turbulent boundary layer. Phys Fluids. 2011;23:1–13.

Jacob B, Olivieri A, Miozzi M, Campana EF, Piva R. Drag reduction by microbubbles in a turbulent boundary layer. Phys Fluids. 2010;22.

Mahdi Heyhat M, Abdi A, Jafarzad A. Performance evaluation and exergy analysis of a double pipe heat exchanger under air bubble injection. Appl Therm Eng. 2018;143:582–93.

Pourhedayat S, Sadighi Dizaji H, Jafarmadar S. Thermal-exergetic behavior of a vertical double-tube heat exchanger with bubble injection. Exp Heat Transf. 2019;32:455–68.

Sadighi Dizaji H, Jafarmadar S, Abbasalizadeh M, Khorasani S. Experiments on air bubbles injection into a vertical shell and coiled tube heat exchanger; exergy and NTU analysis. Energy Convers Manag. 2015;103:973–80.

Winkel ES, Ceccio SL, Dowling DR, Perlin M. Bubble-size distributions produced by wall injection of air into flowing freshwater, saltwater and surfactant solutions. Exp Fluids. 2004;37:802–10.

Ramezanizadeh M, Alhuyi Nazari M, Ahmadi MH, Açıkkalp E. Application of nanofluids in thermosyphons: a review. J Mol Liq. 2018;272:395–402.

Khorasani S, Dadvand A. Effect of air bubble injection on the performance of a horizontal helical shell and coiled tube heat exchanger: an experimental study. Appl Therm Eng. 2017;111:676–83.

Ahmadi AA, Arabbeiki M, Ali HM, Goodarzi M. Configuration and optimization of a minichannel using water – alumina nanofluid by non-dominated sorting genetic algorithm and response surface method. 2020;1–22.

Akpinar EK, Bicer Y. Investigation of heat transfer and exergy loss in a concentric double pipe exchanger equipped with swirl generators. Int J Therm Sci. 2005;44:598–607.

Nandan A, Singh G. Experimental studies on heat transfer performance of shell and tube heat exchanger with air bubble injection. Indian J Sci Technol. 2016;9.

Nandan A, Singh G. Experimental study of heat transfer rate in a shell and tube heat exchanger with air bubble injection. Int J Eng Trans B Appl. 2016;29:1160–6.

Thakur G, Singh G, Thakur M, Kajla S. An experimental study of nanofluids operated shell and tube heat exchanger with air bubble injection. Int J Eng Trans A Basics. 2018;31:136–43.

Thakur G, Singh G. An experimental investigation of heat transfer characteristics of water based Al2O3 nanofluid operated shell and tube heat exchanger with air bubble injection technique. Int J Eng Technol. 2017;6:83–90.

Tariq HA, Anwar M, Malik A, Ali HM. Hydro-thermal performance of normal-channel facile heat sink using TiO2–H2O mixture (Rutile–Anatase) nanofluids for microprocessor cooling. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09838-x.

Khalid SU, Babar H, Ali HM, Janjua MM, Ali MA. Heat pipes: progress in thermal performance enhancement for microelectronics. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09820-7.

Sriharan G, Harikrishnan S, Ali HM. Experimental investigation on the effectiveness of MHTHS using different metal oxide-based nanofluids. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09779-5.

Xia SJ, Chen LG, Sun FR. Optimization for entransy dissipation minimization in heat exchanger. Chin Sci Bull. 2009;54:3587–95.

Wei S, Chen L, Sun F. Constructal entransy dissipation minimization of round tube heat exchanger cross-section. Int J Therm Sci. 2011;50:1285–92. https://doi.org/10.1016/j.ijthermalsci.2011.02.025.

Feng HJ, Chen LG, Xie ZH, Sun FR. Constructal optimization for H-shaped multi-scale heat exchanger based on entransy theory. Sci China Technol Sci. 2013;56:299–307.

Chen L, Feng H, Xie Z, Sun F. Thermal efficiency maximization for H- and X-shaped heat exchangers based on constructal theory. Appl Therm Eng. 2015;91:456–62. https://doi.org/10.1016/j.applthermaleng.2015.08.029.

Feng H, Chen L, Xia S. Constructal design for disc-shaped heat exchanger with maximum thermal efficiency. Int J Heat Mass Transf. 2019;130:740–6. https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.003.

Feng H, Chen L, Wu Z, Xie Z. Constructal design of a shell-and-tube heat exchanger for organic fluid evaporation process. Int J Heat Mass Transf. 2019;131:750–6. https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.105.

Feng H, Xie Z, Chen L, Wu Z, Xia S. Constructal design for supercharged boiler superheater. Energy. 2020;191:116484. https://doi.org/10.1016/j.energy.2019.116484.

Nasirzadehroshenin F, Sadeghzadeh M, Khadang A, Maddah H, Ahmadi MH, Sakhaeinia H, et al. Modeling of heat transfer performance of carbon nanotube nanofluid in a tube with fixed wall temperature by using ANN–GA. Eur Phys J Plus. 2020. https://doi.org/10.1140/epjp/s13360-020-00208-y.

Shahsavar A, Ali HM, Mahani RB, Talebizadehsardari P. Numerical study of melting and solidification in a wavy double-pipe latent heat thermal energy storage system. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09864-9.

Ramezanizadeh M, Nazari MA, Hossein M. Mechanics experimental and numerical analysis of a nanofluidic thermosyphon heat exchanger. 2019;2060. https://doi.org/10.1080/19942060.2018.1518272.

Xie Z, Feng H, Chen L, Wu Z. Constructal design for supercharged boiler evaporator. Int J Heat Mass Transf. 2019;138:571–9.

Wu Z, Feng H, Chen L, Xie Z, Cai C. Pumping power minimization of an evaporator in ocean thermal energy conversion system based on constructal theory. Energy. 2019;181:974–84. https://doi.org/10.1016/j.energy.2019.05.216.

Ramezanizadeh M, Nazari MA. Modeling thermal conductivity of Ag/water nanofluid by applying a mathematical correlation and artificial neural network. 2019;468–74.

Komeilibirjandi A, Hossein A, Akbar R. Thermal conductivity prediction of nanofluids containing CuO nanoparticles by using correlation and artificial neural network. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08838-w.

Maleki A, Elahi M, El M, Assad H, Alhuyi M, Mostafa N, et al. Thermal conductivity modeling of nanofluids with ZnO particles by using approaches based on artificial neural network and MARS. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09373-9.

Dittus FW, Boelter LMK. Heat transfer in automobile radiators of the tubular type. Int Commun Heat Mass Transf. 1985;12:3–22.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sokhal, G.S., Dhindsa, G.S., Sokhal, K.S. et al. Experimental investigation of heat transfer and exergy loss in heat exchanger with air bubble injection technique. J Therm Anal Calorim 145, 727–737 (2021). https://doi.org/10.1007/s10973-020-10192-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10192-1