Abstract

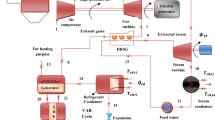

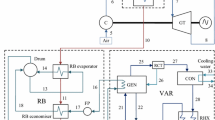

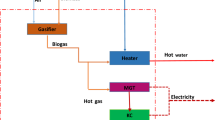

The main purpose of this paper is to study the thermodynamic, economic, and environmental aspects of a integrated system combined cooling, heating, and power generation system empowered by biomass and natural gas. Eco-Indicator 99 method is utilized to quantify the environmental impact. The proposed system consists of four main subsystems producing power, heating, and cooling. Natural gas is mixed with the syngas to enhance its heating value. The results indicate that the exergy efficiency of system is 39.45%, the products cost per exergy unit is 9.71 $ h−1, and the products environmental impact per exergy unit is 4422 mpt GJ−1. Also, when the natural gas mass flow rate-to-syngas mass flow rate ratio increases from 0 to 0.5, the exergy efficiency is found to improve by 71.97%, whereas the products cost per exergy unit and environmental impact per exergy unit of total products are seen to decline by 70.75 and 64.09%, correspondingly. Additionally, the exergy efficiency enhances by 19.48%, while the cost and environmental impact per exergy unit of the total products drop by 13.39 and 13.02%, respectively, as the splitter separation ratio increases from 0 to1.

Graphic abstract

Similar content being viewed by others

Abbreviations

- AC:

-

Air compressor

- ABS:

-

Absorber

- ARC:

-

Absorption refrigeration cycle

- BGC:

-

Biogas compressor

- CC:

-

Combustion chamber

- CCHP:

-

Combined cooling heating power

- CI:

-

Capital investment

- CON:

-

Condenser

- COP:

-

Coefficient of performance

- CRF:

-

Capital recovery factor

- DWH:

-

Domestic water heater

- EVA:

-

Evaporator

- GCU:

-

Gas clean unite

- GMR:

-

Gas mass ratio

- GT:

-

Gas turbine

- HEX:

-

Heat exchanger

- HTHEX:

-

High temperature heat exchanger

- HPG:

-

High pressure generator

- LCOE:

-

Levelized cost of energy

- LPG:

-

Low pressure generator

- LTHEX:

-

Low temperature heat exchanger

- NG:

-

Natural gas

- O&M:

-

Operation and maintenance

- REC:

-

Recuperator

- SR:

-

Split ratio

- SRC:

-

Steam Rankine cycle

- TUR:

-

Turbine

- V:

-

Valve

- A :

-

Heat transfer area (\({\rm {m}}^{2})\)

- \(\dot{B}\) :

-

Environmental impact rate (m Points s−1)

- b :

-

Environmental impact rate per exergy unit (m Points GJ−1)

- \(\dot{C}\) :

-

Cost rate of each stream ($ h−1)

- C :

-

Cost per exergy unit ($ GJ−1)

- \(\dot{E}\) :

-

Exergy rate (kW)

- h :

-

Specific enthalpy (kJ kg−1)

- \(i_{r}\) :

-

Interest rate (%)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \(n\) :

-

Service life

- P :

-

Pressure (kPa)

- \(\dot{Q}\) :

-

Heat rate (kW)

- R :

-

Universal gas constant (kJ kmol−1 K−1)

- \(r_{p}\) :

-

Pressure ratio

- TCI:

-

Total capital investment ($)

- \(\dot{W}\) :

-

Work rate (kW)

- \(Y\) :

-

Component-related environmental impact (mpt)

- \(Z\) :

-

Total annual levelized costs ($)

- η :

-

Efficiency (%)

- \(\Phi\) :

-

Operation and maintenance coefficient

- \(\tau\) :

-

Operation hours (hr)

- \(\varepsilon\) :

-

Exergy efficiency

- η :

-

Efficiency (%)

- ch:

-

Chemical

- CO:

-

Construction

- D:

-

Destruction

- DI:

-

Disposal

- F:

-

Fuel

- Inlet:

-

Inlet condition

- is:

-

Isentropic

- KN:

-

Kinetic

- L:

-

Loss

- ng:

-

Natural gas

- outlet:

-

Outlet condition

- P:

-

Product

- PF:

-

Pollutants formation

- ph:

-

Physical

- PT:

-

Potential

References

Petrakopoulou F, Tsatsaronis G, Morosuk T. Evaluation of a power plant with chemical looping combustion using an advanced exergoeconomic analysis. Sustain Energy Technol Assess. 2013;3:9–16. https://doi.org/10.1016/j.seta.2013.05.001.

Maleki A, Haghighi A, El Haj Assad M, Mahariq I, Alhuyi Nazari M. A review on the approaches employed for cooling PV cells. Sol Energy. 2020;209:170–85. https://doi.org/10.1016/j.solener.2020.08.083.

Ameri M, Mohammadzadeh M. Thermodynamic, thermoeconomic and life cycle assessment of a novel integrated solar combined cycle (ISCC) power plant. Sustain Energy Technol Assess. 2018;27:192–205. https://doi.org/10.1016/j.seta.2018.04.011.

Meyer L, Buchgeister J, Tsatsaronis G, Schebek L. Formation of environmental impacts in energy conversion processes revealed by a novel exergoenvironmental analysis, ASME Int. Mech Eng Congr Expo Proc. 2007;6:409–13. https://doi.org/10.1115/IMECE200742210.

Meyer L, Tsatsaronis G, Buchgeister J, Schebek L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy. 2009;34:75–89. https://doi.org/10.1016/j.energy.2008.07.018.

Meyer L, Castillo R, Buchgeister J, Tsatsaronis G. Application of exergoeconomic and exergoenvironmental analysis to an SOFC system with an allothermal biomass gasifier. Int J Thermodyn. 2009;12:177–86. https://doi.org/10.5541/ijot.1034000255.

Habibi H, Zoghi M, Chitsaz A, Javaherdeh K, Ayazpour M, Bellos E. Working fluid selection for regenerative supercritical Brayton cycle combined with bottoming ORC driven by molten salt solar power tower using energy–exergy analysis. Sustain Energy Technol Assess. 2020;39:100699. https://doi.org/10.1016/j.seta.2020.100699.

Başoğul Y. Environmental assessment of a binary geothermal sourced power plant accompanied by exergy analysis. Energy Convers Manag. 2019;195:492–501. https://doi.org/10.1016/j.enconman.2019.05.033.

Wang W, Wang J, Lu Z, Wang S. Exergoeconomic and exergoenvironmental analysis of a combined heating and power system driven by geothermal source. Energy Convers Manag. 2020;211:112765. https://doi.org/10.1016/j.enconman.2020.112765.

Casas-Ledón Y, Spaudo F, Arteaga-Pérez LE. Exergoenvironmental analysis of a waste-based Integrated Combined Cycle (WICC) for heat and power production. J Clean Prod. 2017;164:187–97. https://doi.org/10.1016/j.jclepro.2017.06.211.

Cavalcanti EJC, Lima MSR, de Souza GF. Comparison of carbon capture system and concentrated solar power in natural gas combined cycle: Exergetic and exergoenvironmental analyses. Renew Energy. 2020;156:1336–1347. https://doi.org/10.1016/j.renene.2019.11.153.

Abusoglu A, Sedeeq MS. Comparative exergoenvironmental analysis and assessment of various residential heating systems. Energy Build. 2013;62:268–77. https://doi.org/10.1016/j.enbuild.2013.03.024.

Blumberg T, Lee YD, Morosuk T, Tsatsaronis G. Exergoenvironmental analysis of methanol production by steam reforming and autothermal reforming of natural gas. Energy. 2019;181:1273–84. https://doi.org/10.1016/j.energy.2019.05.171.

Zhang X, Zeng R, Mu K, Liu X, Sun X, Li H. Exergetic and exergoeconomic evaluation of co-firing biomass gas with natural gas in CCHP system integrated with ground source heat pump. Energy Convers Manag. 2019;180:622–40. https://doi.org/10.1016/j.enconman.2018.11.009.

Moharamian A, Soltani S, Rosen MA, Mahmoudi SMS, Morosuk T. Exergoeconomic analysis of natural gas fired and biomass post-fired combined cycle with hydrogen injection into the combustion chamber. J Clean Prod. 2018;180:450–65. https://doi.org/10.1016/j.jclepro.2018.01.156.

Zainal ZA, Ali R, Lean CH, Seetharamu KN. Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass material. Energy Convers Manag. 2001;42:1499–515. https://doi.org/10.1016/S0196-8904(00)00078-9.

Suresh NS, Thirumalai NC, Dasappa S. Modeling and analysis of solar thermal and biomass hybrid power plants. Appl Therm Eng. 2019;160:114121. https://doi.org/10.1016/j.applthermaleng.2019.114121.

Puig-arnavat M, Bruno JC, Coronas A. Review and analysis of biomass gasification models. Renew Sustain Energy Rev. 2010;14:2841–51. https://doi.org/10.1016/j.rser.2010.07.030.

Safari F, Tavasoli A, Ataei A. Gasification of Iranian walnut shell as a bio-renewable resource for hydrogen-rich gas production using supercritical water technology. Int J Ind Chem. 2017;8:29–36. https://doi.org/10.1007/s40090-016-0093-9.

Hughes EE, Tillman DA. Biomass cofiring: status and prospects fuel process. Technol. 1996;54(1998):127–42. https://doi.org/10.1016/S0378-3820(97)00064-7.

Ruoppolo G, Ammendola P, Chirone R, Miccio F. H 2 -rich syngas production by fluidized bed gasification of biomass and plastic fuel. Waste Manag. 2012;32:724–32. https://doi.org/10.1016/j.wasman.2011.12.004.

Alnouss A, Mckay G, Al-ansari T. A techno-economic-environmental study evaluating the potential of oxygen- steam biomass gasification for the generation of value-added products. Energy Convers Manag. 2019;196:664–76. https://doi.org/10.1016/j.enconman.2019.06.019.

Yang S, Li B, Zheng J, Kumar R. Biomass-to-Methanol by dual-stage entrained flow gasification : design and techno-economic analysis based on system modeling. J Clean Prod. 2018;205:364–74. https://doi.org/10.1016/j.jclepro.2018.09.043.

S. Klein, B. Ouweneel, M. Engineering, S.E. Lab-, A. Society, M. Engineers, A. Society, A. Engineers, A. Solar, E. Society, G. Nellis, J.A. Kaiser, M. Engineering, C. Society, No Title, n.d.

Li J, Mohammadi A, Maleki A. Techno-economic analysis of new integrated system of humid air turbine, organic Rankine cycle, and parabolic trough collector. J Therm Anal Calorim. 2020;139:2691–703. https://doi.org/10.1007/s10973-019-08855-9.

Haghighi A, Pakatchian MR, Assad MEH, Duy VN, Alhuyi Nazari M. A review on geothermal organic rankine cycles: modeling and optimization. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10357-y.

Sanaye S, Khakpaay N, Chitsaz A, Yahyanejad MH. Thermoeconomic and environmental analysis and multi-criteria optimization of an innovative high-efficiency trigeneration system for a residential complex using LINMAP and TOPSIS decision-making methods. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-020-10517-0.

Fakhari I, Behinfar P, Raymand F, Azad A, Ahmadi P, Houshfar E, Ashjaee M. 4E analysis and tri-objective optimization of a triple-pressure combined cycle power plant with combustion chamber steam injection to control NOx emission. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-020-10493-5.

Balafkandeh S, Zare V, Gholamian E. Multi-objective optimization of a tri-generation system based on biomass gasification/digestion combined with S-CO 2 cycle and absorption chiller. Energy Convers Manag. 2019;200:112057. https://doi.org/10.1016/j.enconman.2019.112057.

Golchoobian H, Saedodin S, Ghorbani B. Exergetic and economic evaluation of a novel integrated system for trigeneration of power, refrigeration and freshwater using energy recovery in natural gas pressure reduction stations. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10607-7.

Palacios-bereche R, Gonzales R, Nebra SA. Exergy calculation of lithium bromide–water solution and its application in the exergetic evaluation of absorption refrigeration systems LiBr-H. 2012;36(2):166–181. https://doi.org/10.1002/er.179.

Detchusananard T, Sharma S, Maréchal F. Multi-objective optimization of sorption enhanced steam biomass gasification with solid oxide fuel cell. Energy Convers Manag. 2019;182:412–29. https://doi.org/10.1016/j.enconman.2018.12.047.

Es R, Mehrpooya M, Moosavian SMA. Thermodynamic assessment of an integrated biomass and coal co- gasi fi cation, cryogenic air separation unit with power generation cycles based on LNG vaporization. Energy Convers Manag. 2018;157:438–51. https://doi.org/10.1016/j.enconman.2017.12.026.

Wang J, Yang Y. Energy, exergy and environmental analysis of a hybrid combined cooling heating and power system utilizing biomass and solar energy. Energy Convers Manag. 2016;124:566–77. https://doi.org/10.1016/j.enconman.2016.07.059.

Zhang X, Zeng R, Du T, He Y, Tian H, Mu K, Liu X. Conventional and energy level based exergoeconomic analysis of biomass and natural gas fi red polygeneration system integrated with ground source heat pump and PEM electrolyzer. Energy Convers Manag. 2019;195:313–27. https://doi.org/10.1016/j.enconman.2019.05.017.

Baghernejad A, Yaghoubi M. Exergoeconomic analysis and optimization of an Integrated solar combined cycle system ( ISCCS ) using genetic algorithm. Energy Convers Manag. 2011;52:2193–203. https://doi.org/10.1016/j.enconman.2010.12.019.

Maleki A, Ngo PTT, Shahrestani MI. Energy and exergy analysis of a PV module cooled by an active cooling approach. J Therm Anal Calorim. 2020;141:2475–85. https://doi.org/10.1007/s10973-020-09916-0.

Açıkkalp E, Aras H, Hepbasli A. Advanced exergoeconomic analysis of an electricity-generating facility that operates with natural gas. Energy convers manag. 2014;78:452–60. https://doi.org/10.1016/j.enconman.2013.11.003.

Ekrataleshian A, Pourfayaz F, Ahmadi MH. Thermodynamic and thermoeconomic analyses and energetic and exergetic optimization of a turbojet engine. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10310-z.

Abdollahpour A, Ghasempour R, Kasaeian A, Ahmadi MH. Exergoeconomic analysis and optimization of a transcritical CO2 power cycle driven by solar energy based on nanofluid with liquefied natural gas as its heat sink. J Therm Anal Calorim. 2020;139:451–73. https://doi.org/10.1007/s10973-019-08375-6.

Ghorbani B, Hamedi MH, Shirmohammadi R, Hamedi M, Mehrpooya M. Exergoeconomic analysis and multi-objective Pareto optimization of the C3MR liquefaction process. Sustain Energy Technol Assess. 2016;17:56–67. https://doi.org/10.1016/j.seta.2016.09.001.

Luo D, Huang D. Thermodynamic and exergoeconomic investigation of various SCO2 Brayton cycles for next generation nuclear reactors. Energy Convers Manag. 2020;209:112649. https://doi.org/10.1016/j.enconman.2020.112649.

Kandilli C, Uzel M. Exergoeconomic analysis of photovoltaic thermal systems based on phase change materials and natural zeolites for thermal management. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10574-z.

Mehrpooya M, Ghorbani B, Abedi H. Biodiesel production integrated with glycerol steam reforming process, solid oxide fuel cell (SOFC) power plant. Energy Convers Manag. 2020;206:112467. https://doi.org/10.1016/J.ENCONMAN.2020.112467.

Khanmohammadi S, Atashkari K, Kouhikamali R. Exergoeconomic multi-objective optimization of an externally fi red gas turbine integrated with a biomass gasi fi er. Appl Therm Eng. 2015;91:848–59. https://doi.org/10.1016/j.applthermaleng.2015.08.080.

Aali A, Pourmahmoud N, Zare V. Exergoeconomic analysis and multi-objective optimization of a novel combined flash-binary cycle for Sabalan geothermal power plant in Iran. Energy Convers Manag. 2017;143:377–90. https://doi.org/10.1016/j.enconman.2017.04.025.

Zhang X, Li H, Liu L, Bai C, Wang S, Song Q. Exergetic and exergoeconomic assessment of a novel CHP system integrating biomass partial gasi fi cation with ground source heat pump. Energy Convers Manag. 2018;156:666–79. https://doi.org/10.1016/j.enconman.2017.11.075.

Khani L, Mahmoudi SMS, Chitsaz A, Rosen MA. Energy and exergoeconomic evaluation of a new power/cooling cogeneration system based on a solid oxide fuel cell. Energy. 2016;94:64–77. https://doi.org/10.1016/J.ENERGY.2015.11.001.

Sahu MK. Sanjay, Thermoeconomic investigation of basic and intercooled gas turbine based power utilities incorporating air-film blade cooling. J Clean Prod. 2018;170:842–56. https://doi.org/10.1016/j.jclepro.2017.09.030.

Zhang X, Liu X, Sun X, Jiang C, Li H, Song Q. Thermodynamic and economic assessment of a novel CCHP integrated system taking biomass, natural gas and geothermal energy as co-feeds. Energy Convers Manag. 2018;172:105–18. https://doi.org/10.1016/j.enconman.2018.07.002.

Owebor K, Oko COC, Diemuodeke EO, Ogorure OJ. Thermo-environmental and economic analysis of an integrated municipal waste-to-energy solid oxide fuel cell, gas-, steam-, organic fluid- and absorption refrigeration cycle thermal power plants. Appl Energy. 2019;239:1385–401. https://doi.org/10.1016/J.APENERGY.2019.02.032.

Behzadi A, Habibollahzade A, Ahmadi P, Gholamian E, Houshfar E. Multi-objective design optimization of a solar based system for electricity, cooling, and hydrogen production. Energy. 2019;169:696–709. https://doi.org/10.1016/J.ENERGY.2018.12.047.

Akrami E, Nemati A, Nami H, Ranjbar F. ScienceDirect Exergy and exergoeconomic assessment of hydrogen and cooling production from concentrated PVT equipped with PEM electrolyzer and LiBr-H 2 O absorption chiller. Int J Hydrogen Energy. 2017;1–12. https://doi.org/10.1016/j.ijhydene.2017.11.007.

Cavalcanti EJC, Carvalho M, Jonathan JL. Exergoenvironmental results of a eucalyptus biomass-fired power plant. Energy. 2019. https://doi.org/10.1016/j.energy.2019.116188.

Pavlović A, Nikolić D, Jovanovic S, Bošković G, Skerlić J. Life cycle assessment of the car tire with eco indicator 99 methodology. Mobil Veh Mech. 2019;45(3):13–23. https://doi.org/10.24874/mvm.2019.45.03.02.

Cavalcanti EJC. Exergoeconomic and exergoenvironmental analyses of an integrated solar combined cycle system. Renew Sustain Energy Rev. 2017;67:507–19. https://doi.org/10.1016/j.rser.2016.09.017.

Boyano A, Blanco-Marigorta AM, Morosuk T, Tsatsaronis G. Exergoenvironmental analysis of a steam methane reforming process for hydrogen production. Energy. 2011;36:2202–14. https://doi.org/10.1016/j.energy.2010.05.020.

Boyano A, Morosuk T, Blanco-Marigorta AM, Tsatsaronis G. Conventional and advanced exergoenvironmental analysis of a steam methane reforming reactor for hydrogen production. J Clean Prod. 2012;20:152–60. https://doi.org/10.1016/j.jclepro.2011.07.027.

M. Goedkoop, R. Spriensma, The eco-indicator 99: a damage oriented method for life cycle impact assessment, Methodology annex. https://www.pre-sustainability.com/download/EI99_annexe_v3.pdf;, Pre Concultants. (2001) 1–83 [accessed 17.01.15]. http://ci.nii.ac.jp/naid/10014712580/en/

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jalili, M., Ghasempour, R., Ahmadi, M.H. et al. Exergetic, exergo-economic, and exergo-environmental analyses of a trigeneration system driven by biomass and natural gas. J Therm Anal Calorim 147, 4303–4323 (2022). https://doi.org/10.1007/s10973-021-10813-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10813-3