Abstract

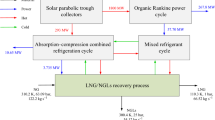

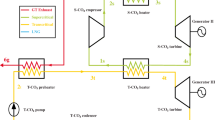

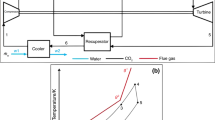

Natural gas compressor stations have a significant potential for waste heat recovery. In this paper, a novel quadruple combined cycle has been proposed based on a turbocompressor gas station. In this regard, Serajeh gas station in Qom (Iran), including three 25 MW nominal gas turbines that each turbine provided power requirement for compressor, has been considered. Steam and organic Rankine cycles have been used to recover waste heat and generate more power, which uses exhaust gas turbines. Seven organic fluids have been examined. Energy, Exergy, Exergoeconomic, Exergoenvironment, Emergoeconomic, and Emergoenvironmental (6E) analyses have better understood the system from different perspectives. In this regard, computer code has been developed in MATLAB for 6E analysis. Verification of thermodynamic simulation of developed code has been compared with THERMOFLEX software and reference data with high accuracy. Also, sensitivity analysis was carried out based on main parameters. Advanced exergy-based analysis associated with endogenous/exogenous and avoidable/unavoidable parts has been performed for deep analysis of each component. The results show an increase of approximately 16% in the integrated cycle's thermal efficiency compared to gas turbines. The combustion chamber has the highest exergy destruction rate, and the LP superheater and economizer have the lowest exergy efficiency. R113 was selected as the best organic fluid from thermodynamic and R141b from an economic and environmental point of view. Cost rates and environmental impacts of the entire system will be approximately 3300 $ h−1 and 2038 pts h−1, respectively.

Similar content being viewed by others

Abbreviations

- HRSG:

-

Heat recovery steam generator

- LP:

-

Low pressure

- HP:

-

High pressure

- Hr:

-

Hour

- ORC:

-

Organic rankine cycle

- RO:

-

Reverse osmosis

- MED:

-

Multi-effect distillation

- MSF:

-

Multi-stage flash

- KC:

-

Kalina cycle

- ISCC:

-

Integrated solar combined cycle

- LNG:

-

Liquefied natural gas

- GT:

-

Gas turbine

- ST:

-

Steam turbine

- ORCT:

-

Organic rankine cycle turbine

- ACC:

-

Air cooled condenser

- ex:

-

Exergy (kJ kg−1)

- Q :

-

Heat transfer (kJ)

- T :

-

Temperature (°C or K)

- m :

-

Mass (kg)

- W :

-

Work (kJ)

- \(\sigma\) :

-

Rupturing stress (Mpa)

- in:

-

Inlet

- out:

-

Outlet

- i:

-

Number of stream

- F:

-

Fuel

- P:

-

Product

- a:

-

Air

- fg:

-

Flue gas

- CA:

-

Cooling air

- h:

-

Enthalpy (kJ kg−1)

- s:

-

Entropy (kJ (kg C)−1)

- x:

-

Quality

- C:

-

Cost of stream ($)

- A:

-

Area (\({\text{m}}^{2}\))

- vel:

-

Velocity (m s−1)

- D:

-

Diameter (m)

- FS:

-

Factor of safety

- Y:

-

Environmental impact (Pts)

- B:

-

Environmental impact of stream (Pts)

- TIT:

-

Turbine inlet temperature (°C or K)

- dp:

-

Relative pressure drop

- TIP:

-

Turbine inlet pressure (bar)

- TTD:

-

Terminal temperature difference (°C or K)

- \(\psi\) :

-

Exergy efficiency

- \(\eta\) :

-

Isentropic efficiency, thermal efficiency

- ρ :

-

Density (kg m−3)

- SC:

-

Steam cycle

- w :

-

Water

- s :

-

Isentropic

- amb:

-

Ambient

- EN:

-

Endogenous

- EX:

-

Exogenous

- UN:

-

Unavoidable

- AV:

-

Avoidable

References

Gómez-Aláez SL, Brizzy V, Alfani D, Silva P, Giostry A, Astolfi M. Off-design study of a waste heat recovery ORC module in gas pipelines recompression station. In: 4th international seminar on ORC power, vol. 129, Italy; 2017. p. 567–74.

Hærvig J, Sørensen K, Condra TJ. Guidelines for optimal selection of working fluid for an organic Rankine cycle in relation to waste heat recovery. Energy. 2016;96:592–602.

Khoshgoftar Manesh MH, Abadi SK, Ghalami H, Amidpour M. Exergoeconomic evaluation of desalinated water production in pipeline gas station. In: Proceedings of the 3rd gas processing symposium, Qatar, vol. 3; 2012. p. 191–98.

Bianchi M, et al. Feasibility of ORC application in natural gas compressor stations. Energy. 2019;173:1–15.

Saavedra I, Bruno JC, Coronas A. Thermodynamic optimization of organic Rankine cycles at several condensing temperatures: case study of waste heat recovery in a natural gas compressor station. Proc Inst Mech Eng Part A J Power Energy. 2010. https://doi.org/10.1243/09576509JPE998.

Kostowski W, Pajączek K, Pociecha A, Kalina J, Niedzielski P, Przybył A. Methods of waste heat recovery—a compressor station case study. Energy Convers Manag. 2019;197:111837.

Mazhari V, Abadi S.K, Ghalami H, Khoshgoftar Manesh M.H, Amidpour M. Techno-economic evaluation of using different air inlet cooling systems in gas compressor station. In: Proceedings of the 3rd gas processing symposium, Qatar; 2012. p. 295–302.

Kostowski WJ, Kalina J, Bargiel P, Szuflenski P. Energy and exergy recovery in a natural gas compressor station—a technical and economic analysis. Energy Convers Manag. 2015;104:17–31.

Li J, Mohammadi A, Maleki A. Techno-economic analysis of new integrated system of humid air turbine, organic Rankine cycle, and parabolic trough collector. J Therm Anal Calorim. 2020;139:2691–703.

Lokare OR, Tavakkoli S, Rodriguez G, Khanna V, Vidic RD. Integrating membrane distillation with waste heat from natural gas compressor stations for produced water treatment in Pennsylvania. Desalination. 2017;413:144–53.

Khoshgoftar Manesh MH, Amidpour M, Khodaei Jalal Abadi H. Comparison of combined cycle and conventional steam power plant through energy level and thermoeconomic analysis. In: ASME 2008 international mechanical engineering congress and exposition; 2008. p. 66640.

Nemati A, Nami H, Ranjbar F, Yari M. A comparative thermodynamic analysis of ORC and Kalina cycles for waste heat recovery: a case study for CGAM cogeneration system. Case Stud Therm Eng. 2017;9:1–13.

Shayan M, Pirouzfar V, Sakhaeinia H. Technological and economical analysis of flare recovery methods, and comparison of different steam and power generation systems. J Therm Anal Calorim. 2020;139:2399–411.

Botros KK, Price GR, Kybria G. Thermodynamic, environmental and economic assessment of exhaust gas recirculation for NOx reduction in gas turbine based compressor station. In: ASME 1999 international gas turbine and aeroengine congress and exhibition.

Xenos DP, Lunde E, Thornhill NF. Optimal operation and maintenance of gas compressor stations: an integrated framework applied to a large-scale industrial case. In: Proceedings of ASME turbo expo 2015: turbine technical conference and exposition GT2015.

Liu B, Liu S, Guo S, Zhang S. Economic study of a large-scale renewable hydrogen application utilizing surplus renewable energy and natural gas pipeline transportation in China. Int J Hydrog Energy. 2020;45:1385–98.

Ahmadi B, Golneshan A, Arasteh H, Karimipour A, Bach Q. Energy and exergy analysis and optimization of a gas turbine cycle coupled by a bottoming organic Rankine cycle. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09088-6.

Zandi S, Golbaten Mofrad K, Salehi G, Khoshgoftar Manesh MH, Fazeli A. Multi-objective optimization and thermoeconomic analysis of a novel CCHP with TES and hybrid cooling for residential complex. Therm Sci Eng Prog. 2020;19:100656.

Golchoobian H, Taheri M, Saedodin S. Thermodynamic analysis of turboexpander and gas turbine hybrid system for gas pressure reduction station of a power plant. Case Stud Therm Eng. 2019;14:100488.

Khoshgoftar Manesh MH, Noori SA. Simulation and optimization of tehran oil refinery steam network in view of exergetic, exergoeconomic and environmental analysis. J Oil Gas Petrochem Technol. 2017;4:55–68.

Bao J, Zhao L. A review of working fluid and expander selections for organic Rankine cycle. Renew Sustain Energy Rev. 2013;24:325–42.

Saleh S, Pirouzfar V, Alihosseini VA. Performance analysis and development of a refrigeration cycle through various environmentally friendly refrigerants. J Therm Anal Calorim. 2019;136:1817–30.

Bonforte G, Buchgeister J, Manfrida G, Petela K. Exergoeconomic and exergoenvironmental analysis of an integrated solar gas turbine/combined cycle power plant. Energy. 2018;156:352–9.

Ersayin E, Ozgener L. Performance analysis of combined cycle power plants: a case study. Renew Sustain Energy Rev. 2015;43:832–42.

Ahmadi P, Dincer I, Rosen MA. Exergy, exergoeconomic and environmental analyses and evolutionary algorithm based multi-objective optimization of combined cycle power plants. Energy. 2011;36:5886–98.

Sanaye S, Amani M, Amani P. 4E modeling and multi-criteria optimization of CCHPW gas turbine plant with inlet air cooling and steam injection. Sustain Energy Technol Assess. 2018;29:70–81.

Ameri M, Mohammadzadeh M. Thermodynamic, thermoeconomic and life cycle assessment of a novel integrated solar combined cycle (ISCC) power plant. Sustain Energy Technol Assess. 2018;27:192–205.

Arabkoohsar A, Sadi M. Thermodynamics, economic and environmental analyses of a hybrid waste–solar thermal power plant. J Therm Anal Calorim. 2020;144:917–40.

Binamer AO. Al-Abdaliya integrated solar combined cycle power plant: case study of Kuwait, part I. Renew Energy. 2019;131:923–37.

Cavalcanti E. Exergoeconomic and exergoenvironmental analyses of an integrated solar combined cycle system. Renew Sustain Energy Rev. 2017;67:507–19.

Islam S, Dincer I. Development, analysis and performance assessment of a combined solar and geothermal energy-based integrated system for multigeneration. Sol Energy. 2017;147:328–43.

Nami H, Mahmoudi SMS, Nemati A. Exergy, economic and environmental impact assessment and optimization of a novel cogeneration system including a gas turbine, a supercritical CO2 and an organic Rankine cycle (GT-HRSG/SCO2). Appl Therm Eng. 2017;110:1315–30.

Mehrpooya M, Ashouri M, Mohammadi A. Thermoeconomic analysis and optimization of a regenerative two-stage organic Rankine cycle coupled with liquefied natural gas and solar energy. Energy. 2017;126:899–914.

Bagherzadeh SA, Ruhani B, Namar MM, Alamian R, Rostami S. Compression ratio energy and exergy analysis of a developed Brayton-based power cycle employing CAES and ORC. J Therm Anal Calorim. 2020;139:2781–90.

Srinivasan KK, Mago PJ, Krishnan SR. Analysis of exhaust waste heat recovery from a dual fuel low temperature combustion engine using an Organic Rankine Cycle. Energy. 2010;35:2387–99.

Adibhatla S, Kaushik SC. Energy, exergy and economic (3E) analysis of integrated solar direct steam generation combined cycle power plant. Sustain Energy Technol Assess. 2017;20:88–97.

Esmaeilzadehazimi MA, Khoshgoftar Manesh MH, Nourpour M, Majidi M. Evaluation of a novel quadruple combined cycle with the magnetohydrodynamic generator based on 6E analysis. J Energy Res Technol. 2020;143:072104.

Abadi SK, Khoshgoftar Manesh MH, Rosen MA, Amidpour M, Hamedi MH. Integration of a gas fired steam power plant with a total site utility using a new cogeneration targeting procedure. Chin J Chem Eng. 2014;22:455–68.

Khoshgoftar Manesh MH, Navid P, Blanco Marigorta AM, Amidpour M, Hamedi MH. New procedure for optimal design and evaluation of cogeneration system based on advanced exergoeconomic and exergoenvironmental analyses. Energy. 2013;59:314–33.

Khoshgoftar Manesh MH, Ameryan M. Optimal design of a solar-hybrid cogeneration cycle using Cuckoo Search algorithm. Appl Therm Eng. 2016;102:1300–13.

Khoshgoftar Manesh MH, Rosen MA. Combined cycle and steam gas-fired power plant analysis through exergoeconomic and extended combined pinch and exergy methods. Energy Eng. 2018;144:04018010.

Nouri M, Namar MM, Jahanian O. Analysis of a developed Brayton cycled CHP system using ORC and CAES based on first and second law of thermodynamics. J Therm Anal Calorim. 2019;135:1743–52.

Rafat E, Babaelahi M, Mofidipour E. Sustainability analysis of low temperature solar-driven kalina power plant using emergy concept. Int J Thermo. 2019;22:118–26.

Aghbashlo M, Rosen MA. Consolidating exergoeconomic and exergoenvironmental analyses using the emergy concept for better understanding energy conversion systems. J Clean Prod. 2018;172:696–708.

Moradi M, Ghorbani B, Shirmohammadi R, Mehrpooya M, Hamedi M-H. Developing of an integrated hybrid power generation system combined with a multi-effect desalination unit. Sustain Energy Technol Assess. 2019;3271–82. https://doi.org/10.1016/j.seta.2019.02.002.

Ghorbani B, Mehrpooya M, Sadeghzadeh M. Process development of a solar-assisted multi-production plant: Power cooling and hydrogen. Int J Hydrog Energy. 2020;45(55):30056–79. https://doi.org/10.1016/j.ijhydene.2020.08.018

Ebrahimi A, Ghorbani B, Taghavi M. Pinch and exergy evaluation of a liquid nitrogen cryogenic energy storage structure using air separation unit liquefaction hybrid process and Kalina power cycle. J Clean Prod. 2021;305127226. https://doi.org/10.1016/j.jclepro.2021.127226.

Golchoobian H, Saedodin S, Ghorbani B. Exergetic and economic evaluation of a novel integrated system for trigeneration of power refrigeration and freshwater using energy recovery in natural gas pressure reduction stations. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10607-7.

Ghorbani B, Mehrpooya M, Shokri K. Developing an integrated structure for simultaneous generation of power and liquid CO2 using parabolic solar collectors solid oxide fuel cell and post-combustion CO2 separation unit. Appl Therm Eng. 2020;179115687. https://doi.org/10.1016/j.applthermaleng.2020.115687.

Rahimi MJ, Ghorbani B, Amidpour M, Hamedi MH. Configuration optimization of a multi-generation plant based on biomass gasification. Energy 2021;227120457. https://doi.org/10.1016/j.energy.2021.120457.

Bonyadi N, Johnson E, Baker D. Technoeconomic and exergy analysis of a solar geothermal hybrid electric power plant using a novel combined cycle. Energy Convers Manag. 2018;156:542–54.

Ezzat MF, Dincer I. Energy and exergy analyses of a novel ammonia combined power plant operating with gas turbine and solid oxide fuel cell systems. Energy. 2019;194:116750.

Barbarelli S, Berardi E, Amelio M, Scornaienchi NM. An externally fired micro combined-cycle with largely adjustable steam turbine, in a CHP system. Proc Manuf. 2020;42:532–7.

Vazini Modabber H, Khoshgoftar Manesh MH. Optimal exergetic, exergoeconomic and exergoenvironmental design of polygeneration system based on gas turbine-absorption chiller-solar parabolic trough collector units integrated with multi-effect desalination-thermal vapor compressor-reverse osmosis desalination systems. Renew Energy. 2020;165:533–52.

Ghorbani S, Khoshgoftar-Manesh MH, Nourpour M, Blanco-Marigorta AM. Exergoeconomic and exergoenvironmental analyses of an integrated SOFC-GT-ORC hybrid system. Energy. 2020;206:118151.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Rights and permissions

About this article

Cite this article

Nourpour, M., Khoshgoftar Manesh, M.H. Modeling and 6E analysis of a novel quadruple combined cycle with turbocompressor gas station. J Therm Anal Calorim 147, 5165–5197 (2022). https://doi.org/10.1007/s10973-021-10898-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10898-w