Abstract

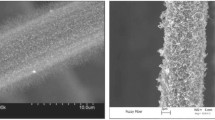

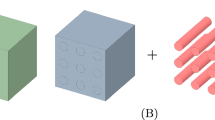

A novel fuzzy fiber reinforced composite (FFRC) reinforced with zig-zag single-walled carbon nanotubes (CNTs) and carbon fibers is proposed. The distinct constructional feature of this composite is that the uniformly aligned CNTs are radially grown on the surface of carbon fibers. Analytical models based on the mechanics of materials approach and the Mori–Tanaka method are derived to estimate the effective elastic constants of this proposed FFRC. The values of the effective elastic properties of this composite are estimated with and without considering an interphase between the CNT and the polymer matrix. It has been found that the transverse effective properties of this composite are significantly improved due to the radial growing of CNTs on the surface of carbon fiber. The effective properties are also found to be sensitive to the CNT diameter.

Similar content being viewed by others

References

Batra, R.C., Sears, A.: Uniform radial expansion/contraction of carbon nanotubes and their transverse elastic moduli. Model. Simul. Mater. Sci. Eng. 15, 835–844 (2007)

Bevensite, Y., Dvorak, G.J.: Uniform fields and universal relations in piezoelectric composites. J. Mech. Phys. Solids 40, 1295–1312 (1992)

Cheng, H.C., Liu, Y.L., Hsu, Y.C., Chen, W.H.: Atomistic-continuum modeling for mechanical properties of single-walled carbon nanotubes. Int. J. Solids Struct. 46, 1695–1704 (2009)

Dunn, M.L., Ledbetter, H.: Elastic moduli of composites reinforced by multiphase particles. ASME J. Appl. Mech. 62, 1023–1028 (1995)

Esteva, M., Spanos, P.D.: Effective elastic properties of nanotube reinforced composites with slightly weakened interfaces. J. Mech. Mater. Struct. 4, 887–900 (2009)

Gao, X.L., Li, K.: A shear-lag model for carbon nanotube reinforced polymer composites. Int. J. Solids Struct. 42, 1649–1667 (2005)

Garcia, E.J., Wardle, B.L., Hart, A.J., Yamamoto, N.: Fabrication and multifunctional properties of a hybrid laminate with aligned carbon nanotubes grown in situ. Compos. Sci. Technol. 68, 2034–2041 (2008)

Gou, J., Minaie, B., Wang, B., Liang, Z., Zhang, C.: Computational and experimental study of interfacial bonding of single-walled nanotube reinforced composites. Comput. Mater. Sci. 31, 225–236 (2004)

Gupta, S.S., Batra, R.C.: Wall thickness and radial breathing modes of single-walled carbon nanotubes. ASME J. Appl. Mech. 75, 061010 (2008)

Honjo, K.: Thermal stresses and effective properties calculated for fiber composites using actual cylindrically-anisotropic properties of interfacial carbon coating. Carbon 45, 865–872 (2007)

Iijima, S.: Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991)

Jiang, Y.L., Martin, L.D.: Anisotropic coupled-field inclusion and inhomogeneity problems. Philos. Mag. A 77(5), 1341–1350 (1998)

Jiang, B., Liu, C., Zhang, C., Liang, R., Wang, B.: Maximum nanotube volume fraction and its effect on overall elastic properties of nanotube-reinforced composites. Composites B 40, 212–217 (2009)

Li, C., Chou, T.W.: A structural mechanics approach for the analysis of carbon nanotubes. Int. J. Solids Struct. 40, 2487–2499 (2003)

Lu, J.P.: Elastic properties of carbon nanotubes and nanoropes. Phys. Rev. Lett. 79, 1297–1300 (1997)

Mathur, R.B., Chatterjee, S., Singh, B.P.: Growth of carbon nanotubes on carbon fiber substrates to produce hybrid/phenolic composites with improved mechanical properties. Compos. Sci. Technol. 68, 1608–1615 (2008)

Meguid, S.A., Zhu, Z.H.: A novel finite element for treating inhomogeneous solids. Int. J. Numer. Methods Eng. 38, 1579–1592 (1995)

Meguid, S.A., Wernik, J.M., Cheng, Z.Q.: Atomistic-based continuum representation of the effective properties of nano-reinforced epoxies. Int. J. Solids Struct. 47, 1723–1736 (2010)

Mori, T., Tanaka, K.: Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 21, 571–574 (1973)

Odegard, G.M., Gates, T.S., Wise, K.E., Park, C., Siochi, E.J.: Constitutive modeling of nanotube-reinforced polymer composites. Compos. Sci. Technol. 63, 1671–1687 (2003)

Odegard, G.M., Clancy, T.C., Gates, T.S.: Modeling of the mechanical properties of nanoparticle/polymer composites. Polymer 46, 553–562 (2005)

Qui, Y.P., Weng, G.J.: On the application of Mori-Tanaka’s theory involving transversely isotropic spheroidal inclusions. Int. J. Eng. Sci. 28(11), 1121–1137 (1990)

Ray, M.C.: Concept for a novel hybrid smart composite reinforced with radially aligned zigzag carbon nanotubes on piezoelectric fibers. Smart Mater. Struct. 19, 035008 (2010)

Ray, M.C., Batra, R.C.: Effective properties of carbon nanotube and piezoelectric fiber reinforced hybrid smart composite. ASME J. Appl. Mech. 76, 034–503 (2009)

Ray, M.C., Guzman de Villoria, R., Wardle, B.L.: Load transfer analysis in short carbon fibers with radially-aligned carbon nanotubes embedded in a polymer matrix. J. Adv. Mater. 41(4), 82–94 (2009)

Rio, T.G., Poza, P., Rodriguez, J., Garcia, M.C., Hernandez, J.J., Ezquerra, T.A.: Influence of single-walled carbon nanotubes on the effective elastic constants of poly (ethylene terephthalate). Compos. Sci. Technol. 70, 284–290 (2010)

Shen, L., Li, J.: Transversely isotropic elastic properties of single-walled carbon nanotubes. Phys. Rev. B 69, 045–414 (2004)

Smith, W.A., Auld, B.A.: Modeling 1–3 composite piezoelectrics: thickness mode oscillations. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 38(1), 40–47 (1991)

Song, Y.S., Youn, J.R.: Modeling of effective elastic properties for polymer based carbon nanotube composites. Polymer 47, 1741–1748 (2006)

Thostenson, E.T., Chow, T.W.: On the elastic properties of carbon nanotube based composites: modeling and characterization. J. Phys. D 36, 573–582 (2003)

Treacy, M.M.J., Ebbessen, T.W., Gibson, J.M.: Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 381, 678–680 (1996)

Tsai, J.L., Tzeng, S.H., Chiu, Y.T.: Characterizing elastic properties of carbon nanotube/polyimide nanocomposites using multi-scale simulation. Composites B 41, 106–115 (2010)

Wernik, J.M., Meguid, S.A.: Multiscale modeling of the nonlinear response of nano-reinforced polymers. Acta Mech. 217, 1–16 (2011)

Xiao, J.R., Gama, B.A., Gillespie, J.W.: An analytical molecular structural mechanics model for the mechanical properties of carbon nanotubes. Int. J. Solids Struct. 42, 3075–3092 (2005)

Zhang, J., He, C.: A three-phase cylindrical shear-lag model for carbon nanotube composites. Acta Mech. 196, 33–54 (2008)

Zhang, Q., Qian, W., Xiang, R., Yang, Z., Luo, G., Wang, Y., Wei, F.: In situ growth of carbon nanotubes on inorganic fibers with different surface properties. Mater. Chem. Phys. 107, 317–321 (2008)

Author information

Authors and Affiliations

Corresponding author

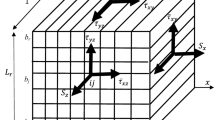

Appendix

Appendix

Equation 30 as shown in the results and discussion section can be derived as follows:

Referring to Fig. 6, the RVE of the FFRC can be considered as an equilateral triangle. Thus the volume (\( {\mathbf{V}}^{{{\mathbf{FFRC}}}} \)) of the RVE of the FFRC is given by

where D = 2R. The volume (V f) of the carbon fiber is

where d = 2a. Thus the carbon fiber volume fraction (v f ) in the FFRC can be expressed as

Using A (3), the carbon fiber volume fraction (\( {\bar{\mathbf{v}}}_{\mathbf{f}} \)) in the CFF can be derived as

The maximum number \( \left( {{\mathbf{N}}_{{{\mathbf{CNT}}}} } \right)_{ \max } \) of radially grown aligned CNTs on the surface of the carbon fiber is given by

Therefore the volume (V CNT) of the CNTs is

Thus the maximum volume fraction \( \left( {{\mathbf{v}}_{{{\mathbf{CNT}}}} } \right)_{ \max } \) of the CNT with respect to the volume of the FFRC can be determined as

Finally, the maximum volume fraction (max (v nt )) of the CNTs with respect to the volume of the PMNC and with respect to the volume of the CFF (max (\( {\bar{\mathbf{v}}}_{\mathbf{nt}} \))) can be determined in terms of max (v CNT ) as follows:

Rights and permissions

About this article

Cite this article

Kundalwal, S.I., Ray, M.C. Micromechanical analysis of fuzzy fiber reinforced composites. Int J Mech Mater Des 7, 149–166 (2011). https://doi.org/10.1007/s10999-011-9156-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-011-9156-4