Abstract

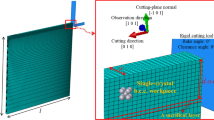

In recent years thanks to enhancements in design of advanced machines, laser metrology and computer control, ultra-precision machining has become increasingly important. In micromachining of metals the depth of cut is usually less than the average grain size of a polycrystalline aggregate; hence, a cutting process can occur entirely within a single crystal. The respective effect of crystallographic anisotropy requires development of machining models that incorporate crystal plasticity for an accurate prediction of micro-scale material removal under such conditions. To achieve this, a 3D finite-element model of orthogonal micro-cutting of a single crystal of b.c.c. brass was implemented in a commercial software ABAQUS/Explicit using a user-defined subroutine VUMAT. Strain-gradient crystal-plasticity theories were used to demonstrate the influence of evolved strain gradients on the cutting process for different cutting directions.

Similar content being viewed by others

References

Lawson BL, Kota N, Ozdoganlar OB (2008) Effects of crystallographic anistropy on orthogonal micromachining of single-crystal aluminum. J Manuf Sci Eng 130(3):031116

Sato M, Kato K, Tuchiya K (1978) Effect of material and anisotropy upon the cutting mechanism. Trans Jpn Inst Met 9:530–536

Sato M, Kato Y, Aoki S, Ikoma A (1983) Effects of crystal orientation on the cutting mechanism of the aluminum single crystal: 2nd report: on the (111) plane and the (112) end cutting. Bull JSME 26(215):890–896

Shirakashi T, Yoshino M, Kurashima H (1991) Study on cutting mechanism of single crystal based on simple shear plane model. Int J Jpn Soc Precis Eng 25(2):96–97

Lee WB, Zhou M (1993) A theoretical analysis of the effect of crystallographic orientation on chip formation in micromachining. Int J Mach Tools Manuf 33:439–447

Lee WB, Cheung CF, To S (2002) A microplasticity analysis of micro-cutting force variation in ultra-precision diamond turning. J Manuf Sci Eng 124(2):170–177

Kota N, Ozdoganlar OB (2010) A model-based analysis of orthogonal cutting for single-crystal fcc metals including crystallographic anisotropy. Mach Sci Technol 14(1):102–127

Liang Y, Moronuki N, Furukawa Y (1994) Calculations of the effect of material anisotropy on microcutting processes. Precis Eng 16(2):132–138

Liu K, Melkote SN (2007) Finite element analysis of the influence of tool edge radius on size effect in orthogonal micro-cutting process. Int J Mech Sci 49:650–660

Zahedi SA, Demiral M, Roy A, Silberschmidt VV (2013) FE/SPH modelling of orthogonal micro-machining of f.c.c. single crystal. Comput Mater Sci 78:104–109

Demiral M, Roy A, El Sayed T, Silberschmidt VV (2014) Numerical modelling of micro-machining of fcc single crystal: influence of strain gradients. Comput Mater Sci 94:273–278

Huang Y, Qu S, Hwang KC, Li M, Gao H (2004) A conventional theory of mechanism-based strain gradient plasticity. Int J Plast 20(4):753–782

Ertürk I, Van Dommelen JAW, Geers MGD (2014) Gradient crystal plasticity modelling of anelastic effects in particle strengthened metallic thin films. Meccanica 49:2657–2685

Demiral M (2012) Enhanced gradient crystal-plasticity study of size effects in b.c.c. metal. Dissertation, Loughborough University, UK

Arsenlis A, Parks DM, Becker R, Bulatov VV (2004) On the evolution of crystallographic dislocation density in non-homogeneously deforming crystals. J Mech Phys Solids 52(6):1213–1246

Bardella L (2006) A deformation theory of strain gradient crystal plasticity that accounts for geometrically necessary dislocations. J Mech Phys Solids 54(1):128–160

Kuroda M, Tvergaard V (2008) On the formulations of higher-order strain gradient crystal plasticity models. J Mech Phys Solids 56(4):1591–1608

Gurtin ME (2008) A finite-deformation, gradient theory of single-crystal plasticity with free energy dependent on densities of geometrically necessary dislocations. Int J Plast 24(4):702–725

Dassault Systemes (2013) Abaqus 6. 13 analysis user manual

Ueda K, Iwata K, Nakayama K (1980) Chip formation mechanism in single crystal cutting of β-brass. CIRP Ann Manuf Tech 29(1):41–46

Jona F, Marcus PM (2001) Structural and elastic properties of β-brass. J Phys: Condens Matter 13(23):5507

Jia N, Roters F, Eisenlohr P, Kords C, Raabe D (2012) Non-crystallographic shear banding in crystal plasticity FEM simulations: example of texture evolution in α-brass. Acta Mater 60(3):1099–1115

Beyerlein IJ, Mara NA, Bhattacharyya D, Alexander DJ, Necker CT (2011) Texture evolution via combined slip and deformation twinning in rolled silver–copper cast eutectic nanocomposite. Int J Plast 27(1):121–146

Peirce D, Asaro R, Needleman A (1982) An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall 30:1087–1119

Schulze D, Paufler P (1979) Physikalische Grundlagenmechanischer Festkörpereigenschaften. Akademie-Verlag, Berlin

Lee WB (1990) Prediction of microcutting force variation in ultra-precision machining. Precis Eng 12(1):25–28

Tajalli SA, Movahhedy MR, Akbari J (2014) Simulation of orthogonal micro-cutting of FCC materials based on rate-dependent crystal plasticity finite element model. Comput Mater Sci 86:79–87

Demiral M, Roy A, El Sayed T, Silberschmidt VV (2014) Influence of strain gradients on lattice rotation in nano-indentation experiments: a numerical study. Mater Sci Eng, A 94:273–278

Niordson CF, Hutchinson JW (2003) On lower order strain gradient plasticity theories. Eur J Mech A Solids 22(6):771–778

Demiral M, Roy A, Silberschmidt VV (2013) Indentation studies in bcc crystals with enhanced model of strain-gradient crystal plasticity. Comput Mater Sci 79:896–902

Acknowledgments

M.D. was supported with a fellowship from The Scientific and Technological Research Council of Turkey (TÜBITAK 2232, Project No: 114C199). A.R. and V.S. acknowledge funding from the Engineering and Physical Sciences Research Council (UK) through Grant EP/K028316/1 and Department of Science and Technology (India), project MAST.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

An enhanced modelling scheme for a strain-gradient crystal-plasticity (EMSGCP) theory proposed by Demiral [14] was used in the simulations. In the EMSGCP theory, the critical resolved shear stress (CRSS) (\( g_{T}^{\alpha } |_{t = 0} \)) is governed by the initial strength of slip systems related to SSDs (\( g_{S}^{\alpha } |_{t = 0} \)) and GNDs (\( g_{G}^{\alpha } |_{t = 0} \)), linked with initial SSD (\( \rho_{S} |_{t = 0} \)) and GND (\( \rho_{G} |_{t = 0} \)) densities via the constant, K:

The GND density term was expressed as a function of the normalized surface-to-volume \( \left( {{{\bar{S}} \mathord{\left/ {\vphantom {{\bar{S}} {\bar{V}}}} \right. \kern-0pt} {\bar{V}}}} \right) \) ratio (hence, dimensionless) for the component under study [30]. The slip resistance during loading evolves with hardening due to the SSDs (\( \Delta g_{S}^{\alpha } \)) and GNDs (\( \Delta g_{G}^{\alpha } \)) on the slip system as follows:

where \( h_{\alpha \beta } \), α T , μ, b and \( n_{G}^{\alpha } \) corresponds to the slip-hardening modulus, the Taylor coefficient, the shear modulus, the Burgers vector and the effective density of geometrically necessary dislocations, respectively.

The hardening model proposed by Peirce et al. [24] was used to describe \( h_{\alpha \beta } \), as follows:

where h 0 is the initial hardening parameter, \( g_{T}^{\alpha } |_{\text{sat}} \) is the saturation stress of the slip system α, q is the latent hardening ratio, and \( \tilde{\gamma } \) is the Taylor cumulative shear strain on all slip systems. The effective GND density (\( n_{G}^{\alpha } \)) is given by

where \( \varvec{s}^{\alpha } \) is the slip direction, \( \varvec{m}^{\alpha } \) is the slip-plane normal, \( s^{\alpha \beta } = \varvec{s}^{\alpha } .\varvec{s}^{\beta } \) and ∇γ β is the gradient of shear strain in each slip system [24].

In Eq. (2), \( \dot{\gamma }^{\alpha } \) is the shearing rate on the slip system α expressed by the following power-law equation:

where \( \dot{\gamma }_{0}^{\alpha } \), n, τ α and \( g_{T}^{\alpha } \) are the reference strain rate, the macroscopic rate-sensitivity parameter, the resolved shear stress, the strength of the slip system α at the current time, respectively, and \( \text{sgn} ( * ) \) is the signum function of *. In an enhanced model of crystal-plasticity (EMCP) \( \Delta g_{G}^{\alpha } \) is assumed to be equal to 0.

Rights and permissions

About this article

Cite this article

Demiral, M., Roy, A. & Silberschmidt, V.V. Strain-gradient crystal-plasticity modelling of micro-cutting of b.c.c. single crystal. Meccanica 51, 371–381 (2016). https://doi.org/10.1007/s11012-015-0280-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-015-0280-3