Abstract

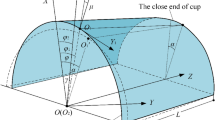

A harmonic drive is a two gear epicyclic drive with a gear set of circular ring gear (RG), a flex rimmed external toothed gear (FG) and an oval cam. FG, with oval cam inside, takes non-circular gear shape encounters improper teeth mating with RG, having only two teeth difference. Consequently, interferences occur at several tooth pairs even at no load. These are inherent and obvious. Overcoming such interferences and further with applied load estimation of load sharing by tooth pairs poses a complex problem. In solving it, first, tooth stiffness of internal gear and external gear are derived in the present investigation. A method of estimating the load shared by the multiple tooth pairs in contact is proposed. The load distribution pattern in proportion to the tooth deformation is considered. Load shared by contacting tooth pairs is estimated and stresses in FG cup are found out using FEM. Finally, such results are compared with experimental results, which have good agreement.

Similar content being viewed by others

Abbreviations

- B:

-

Width of gear tooth (mm)

- E:

-

Young’s modulus (N/mm2)

- F:

-

Force acting on a tooth (N)

- \({\text{F}}_{{{\text{Inter}},{\text{RG}}}} ,{\text{F}}_{{{\text{Inter}},{\text{FG}}}}\) :

-

Load shared by RG and FG tooth in order to avoid interference before application of external load (N)

- \({\text{F}}_{{{\text{RG}},{\text{net}},{\text{i}}}} ,{\text{F}}_{{{\text{FG}},{\text{net}},{\text{i}}}}\) :

-

Load shared by RG and FG tooth while externally force F is applied to the assembled FG–RG teeth (N)

- Ki :

-

Stiffness of a tooth (N/mm)

- \({\text{K}}_{{{\text{FG}},{\text{i}}}} \,{\text{and}}\,{\text{K}}_{{{\text{RG}},{\text{i}}}}\) :

-

Stiffness of flex-gear and ring gear tooth correspond to \(\updelta_{{{\text{FG}},{\text{i}}}}\) and \(\updelta_{{{\text{RG}},{\text{i}}}}\) (N/mm)

- \({\text{K}}_{{{\text{FG}} - {\text{RG}},{\text{i}}}}\) :

-

Combined stiffness of a meshing tooth pair correspond to \({\text{K}}_{{{\text{FG}},{\text{i}}}}\) and \({\text{K}}_{{{\text{RG}},{\text{i}}}}\) (N/mm)

- Y,Yi,Y1,y, Xa, Xb, ψ:

-

Tooth related parameter of external gear tooth related to Fig. 5

- Z:

-

Number of teeth in general

- ZFG/Zp :

-

Teeth number in flexspline/flex-gear

- ZRG/Zg :

-

Teeth number in circular spline/ring gear

- a:

-

Semi major axis (mm)

- af :

-

Addendum factor

- b:

-

Semi minor axis (mm)

- df :

-

Dedendum factor

- hm, tF :

-

Tooth related parameter of internal gear tooth related to Fig. 6

- m:

-

Module of the gear (mm)

- ri :

-

Inner cup radius (mm)

- rb :

-

Radius of base circle of undeformed FG cup tooth (mm)

- rd :

-

Radius of dedendum circle of undeformed FG cup tooth (mm)

- \({\text{t}}_{\text{p}}\) :

-

Pitch circle thickness of FG cup tooth corresponds to correction factor (mm)

- x:

-

Correction/profile modification factor for FG cup teeth

- α:

-

Pressure angle (deg)

- ν:

-

Poisson’s ratio

- \(\uprho_{1} ,\,\uprho_{2}\) :

-

Radius of curvature at the point of contact of external (FG) and internal (RG) tooth respectively (mm)

- \(\updelta_{{{\text{T}}_{\text{E}} }} =\updelta_{{{\text{FG}},{\text{i}}}} ,\updelta_{{{\text{T}}_{\text{i}} }} =\updelta_{{{\text{RG}},{\text{i}}}}\) :

-

Total deflection of external and internal tooth respectively (mm)

- \(\updelta_{{{\text{B}}_{\text{E}} }} ,\updelta_{{{\text{C}}_{\text{E}} }} ,\updelta_{{{\text{S}}_{\text{E}} }} ,\updelta_{{{\text{G}}_{\text{E}} }}\) :

-

Bending, contact, shearing and foundation deformation of external gear tooth (mm)

- \(\updelta_{{{\text{t}}_{\text{i}} }}\) :

-

Combined deformation due to bending, shearing and foundation of internal tooth (mm)

- \(\updelta_{{{\text{C}}_{\text{i}} }}\) :

-

Contact deformation of internal tooth (mm)

- \(\updelta_{{{\text{Inter}},{\text{RG}}}} ,\updelta_{{{\text{Inter}},{\text{FG}}}}\) :

-

Deflection shared by RG and FG tooth in order to avoid interference (mm)

- \(\updelta \uptheta _{{{\text{Inter}},{\text{RG}}}} ,\updelta \uptheta _{{{\text{Inter}},{\text{FG}}}}\) :

-

Angular deflection at the centre of flex-gear correspond to \(\updelta_{{{\text{Inter}},{\text{RG}}}}\), \(\updelta_{{{\text{Inter}},{\text{FG}}}}\)(deg)

- \(\updelta_{{{\text{RG}},{\text{F}},{\text{i}}}} ,\updelta_{{{\text{FG}},{\text{F}},{\text{i}}}}\) :

-

Deflection of RG and FG tooth due to externally applied force F only (mm)

- \(\updelta \uptheta _{{{\text{RG}},{\text{F}},{\text{i}}}} ,\updelta \uptheta _{{{\text{FG}},{\text{F}},{\text{i}}}}\) :

-

Angular deflection at the centre of flex-gear correspond to \(\updelta_{{{\text{RG}},{\text{F}},{\text{i}}}}\), \(\updelta_{{{\text{FG}},{\text{F}},{\text{i}}}}\)(deg)

- \(\updelta_{{{\text{RG}},{\text{net}},{\text{i}}}} ,\updelta_{{{\text{FG}},{\text{net}},{\text{i}}}}\) :

-

Deflection of RG and FG tooth while externally force F is applied to the assembled FG–RG teeth (mm)

- \(\updelta \uptheta _{{{\text{RG}},{\text{net}},{\text{i}}}} ,\updelta \uptheta _{{{\text{FG}},{\text{net}},{\text{i}}}}\) :

-

Angular deflection at the centre of flex-gear correspond to \(\updelta_{{{\text{RG}},{\text{net}},{\text{i}}}}\),\(\updelta_{{{\text{FG}},{\text{net}},{\text{i}}}}\)(deg)

References

Musser CW (1955) Strain Wave Gearing. U.S. Patent No. 2,906,143

Musser CW (1960) Breakthrough in mechanical drive design: the harmonic drive. Mach Des 14:160–172

Routh B and Maiti R (2011) On a gearing problem in conventional harmonic drives with involute toothed gear set. In: ASME IDETC/CIE conference on PTG; Paper No. DETC2011-48849, Washington , pp 481–489

Routh B, Maiti R, Ray AK, Sobczyk A (2015) An investigation on secondary force contacts of tooth pairs in conventional harmonic drives with involute toothed gear set. In: Proceedings of IMechE (UK), Journal of Mechanical Engineering Science, Part C 230(4):622–638. doi:10.1177/0954406215577983

Ostapski W, Mukha I (2007) Stress state analysis of harmonic drive elements by FEM. Bull Pol Acad Sci 55(1):115–123

Chen XX, Lin SZ, Xing JZ (2009) Modeling of flexspline and contact analyses of harmonic drive. Key Eng Mater 419–420:597–600

Dong H (2009) Elastic deformation characteristic of the flexspline in harmonic drive. In: IEEE, reconfigurable mechanisms and robots, pp 363–369, London

XiangGuo Q (2005) Analysis and study on the flexible wheel of harmonic gear drive by finite element method. Master’s thesis dissertation, Sichuan University

Oguz K, Fehmi E (2007) Shape optimization of tooth profile of a flex-spline for a harmonic drive by finite element modeling. Mater Des 28:441–447

Zou C, Tao T, Jiang G , Mei X (2013) Deformation and stress analysis of short flexspline in the harmonic derive system with load. In: IEEE international conference on mechatronics and automation, 4–7 Aug 2013, Takamatsu

Margulis M, Volkov D (1987) Calculation of the torsional rigidity of a harmonic power drive with a disc generator. Sov Eng Res 7(6):17–19

Kikuchi M, Nitta R, Kiyosawa Y (2003) Stress analysis of cup type strain wave gearing. Key Eng Mater 243–244:129–134

Xiao Q, Han X, Jia H (2011) Dynamic optimum design and analysis of cam wave generator for harmonic gear drive. In: IEEE international conference on information and automation, Shenzhen, June 2011

Dong H, Zhu Z, Zhou W, Chen Z (2012) Dynamic simulation of harmonic gear drives considering tooth profile parameters optimization. J Comput 7(6):1429–1436

Conry TF, Serireg A (1971) A mathematical programming method for design of elastic bodies in contact. Trans ASME J Appl Mech 38(2):387–392

Conry TF, Serireg A (1973) A mathematical programming method for evaluation of load distribution and optimal modifications for gear system. Trans ASME J Eng Ind 95(4):1115–1122

Li S (2002) Gear contact model and loaded tooth contact analysis of a three-dimensional, thin-rimmed gear. Trans ASME J Mech Des 124(3):511–517

Li S (2008) Contact problem and numeric method of a planetary drive with small teeth number difference. Mech Mach Theory 43(9):1065–1086

Sahoo V, Maiti R (2016) Static load sharing by tooth pairs in contact in internal involute spur gearing with thin rimmed pinion. Proc Inst Mech Eng Part C J Mech Eng Sci 230(4):485–499

Sahoo V, Maiti R (2016) State of stress in strain wave gear flexspline cup on insertion of drive cam-experiment and analysis. In: The 2016 international conference of Mech. Engg. (ICME’16), London, 29 June–1 July 2016

Sahoo V, Maiti R (2016) Evidence of secondary tooth contact in harmonic drive, with involute toothed gear pair, through experimental and finite element analyses of stresses in flex-gear cup. Proc Inst Mech Eng Part C J Mech Eng Sci. doi:10.1177/0954406216682541

Oda S, Miyachika K, Shimizu H (1986) Practical formula for tooth deflection of internal spur gear. Bull JSME 29(257):3905–3910

Budynas RG, Nisbett JK (2011) Shigley’s mechanical engineering design, 9th edn. McGraw Hill Education (India) Pvt. Ltd, New Delhi, p 764

Acknowledgements

This research work is an outcome of the general PhD programme in the authors’ Institute, IIT Kharagpur, India. There is no specific financial grant for this investigation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Rights and permissions

About this article

Cite this article

Sahoo, V., Maiti, R. Load sharing by tooth pairs in involute toothed harmonic drive with conventional wave generator cam. Meccanica 53, 373–394 (2018). https://doi.org/10.1007/s11012-017-0698-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-017-0698-x