Abstract

Use of porous materials in fluid film is well established so as to make more uniform distribution of pressure along the journal surface. The work presented in this paper deals with theoretical examination into the effect of worn bearing surface on the behaviour of a hybrid double layer porous journal bearing system (DLPJBS) operating with power-law lubricants. The governing equation for the flow of non-Newtonian lubricant in the bearing porous clearance space is solved by using the FEM. The effects of non-Newtonian lubricant on the bearing characteristics of a worn bearing have been studied. Findings of this study indicates that the hybrid DLPJBS operating under non-Newtonian lubricant offers enhanced values of \({\bar{h}}_{min}\), \({\bar{\omega}}_{th}\) and rotor dynamic coefficients (stiffness and damping coefficients).

Similar content being viewed by others

Abbreviations

- \( {\text{c}} \) :

-

Radial clearance (mm)

- \( C_{ij} \) :

-

Fluid film damping coefficients (\( i,j = x,z \)) (N s mm−1)

- \( D \) :

-

Diameter of journal (mm)

- \( e \) :

-

Journal eccentricity (mm)

- \( F_{xo} , F_{zo} \) :

-

Components of fluid film reaction (N)

- \( F_{o} \) :

-

Fluid film reaction (N)

- \( g \) :

-

Acceleration due to gravity (mm s−2)

- \( h \) :

-

Nominal fluid film thickness (mm)

- \( \Delta h \) :

-

Change in bearing geometry due to wear (mm)

- \( H \) :

-

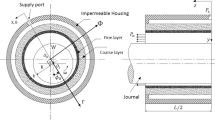

Wall thickness of porous bearing, (mm), (Fig. 1b)

- \( H_{1} \) :

-

Thickness of inner layer of porous bearing (mm), (Fig. 1b)

- \( L \) :

-

Length of bearing (mm)

- \( k_{1} \) :

-

Permeability of inner layer of porous material (mm2)

- \( k_{2} \) :

-

Permeability of outer layer porous material (mm2)

- \( M_{j} ,M_{c} \) :

-

Journal mass, critical mass (kg)

- \( n \) :

-

Power-law index

- \( Q \) :

-

Lubricant flow of oil (mm3 s−1)

- \( p \) :

-

Pressure (N mm −2)

- \( p_{1} \) :

-

Pressure in the inner layer of porous matrix (N mm −2)

- \( p_{2} \) :

-

Pressure in the outer layer of porous matrix (N mm −2)

- \( p_{s} \) :

-

Supply pressure (N mm −2)

- \( R_{j} \) :

-

Radius of journal (mm)

- \( S_{ij} \) :

-

Fluid film stiffness coefficients (\( i,j = x,z \)) (N mm −1)

- \( T_{f} \) :

-

Frictional torque, (N mm)

- \( t \) :

-

Time (s)

- \( U \) :

-

Velocity of Journal (mm s −1)

- \( W_{o} \) :

-

External load (N)

- \( X,Y,Z \) :

-

Cartesian coordinates

- \( X_{j} , Z_{j} \) :

-

Journal centre coordinates

- \( \alpha \) :

-

\( \frac{x}{{R_{j} }} \), Circumferential coordinate

- \( \beta \) :

-

\( \frac{y}{{R_{j} }} \), Axial coordinate

- \( \mu \) :

-

Apparent viscosity of lubricant (N s m −2)

- \( \mu_{r} \) :

-

Reference viscosity of lubricant (N s m −2)

- \( \omega_{j} \) :

-

Journal rotational speed (rad s −1)

- \( \delta_{w} \) :

-

Wear depth (mm)

- \( \tau \) :

-

Shear stress (N mm −2)

- \( \dot{\gamma } \) :

-

Shear strain rate (s −1)

- \( \emptyset \) :

-

Attitude angle, (rad)

- \( \omega_{I} \) :

-

\( \left( {\frac{g}{c}} \right)^{1/2} \) (rad s−1)

- \( \omega_{th} \) :

-

Threshold speed (rad s−1)

- \( \varepsilon \) :

-

\( \left( {\frac{e}{c}} \right) \)

- \( \bar{h} \) :

-

\( \left( {\frac{h}{c}} \right) \)

- \( \Delta \bar{h} \) :

-

\( \left( {\frac{\Delta h}{c}} \right) \)

- \( \bar{h}_{min} \) :

-

\( \left( {\frac{{h_{min} }}{c}} \right) \)

- \( \overline{H}_{1} \) :

-

\( \left( {\frac{{H_{1} }}{L}} \right) \)

- \( \overline{H} \) :

-

\( \left( {\frac{H}{L}} \right) \)

- \( \overline{F}_{xo} ,\overline{F}_{zo} \) :

-

\( \left( {\frac{{F_{xo} ,F_{zo} }}{{p_{s} R_{j}^{2} }}} \right) \)

- \( \overline{C}_{ij} \) :

-

\( C_{ij} \left( {\frac{{c^{3} }}{{\mu R_{j}^{4} }}} \right) \)

- \( \overline{Q} \) :

-

\( Q\left( {\frac{\mu }{{c^{3} p_{s} }}} \right) \)

- \( \overline{M}_{j} ,\overline{M}_{c} \) :

-

\( M_{j} ,M_{c} \left( {\frac{{\mu R_{j}^{4} }}{{\omega_{j} c^{3} }}} \right) \)

- \( \overline{p} \) :

-

\( \frac{p}{{p_{s} }} \)

- \( \overline{p}_{1} \) :

-

\( \frac{{p_{1} }}{{p_{s} }} \)

- \( \overline{p}_{2} \) :

-

\( \frac{{p_{2} }}{{p_{s} }} \)

- \( \overline{p}_{max} \) :

-

\( \frac{{p_{max} }}{{p_{s} }} \)

- \( \overline{\delta }_{w} \) :

-

\( \left( {\frac{{\delta_{w} }}{c}} \right) \)

- \( \overline{S}_{ij} \) :

-

\( S_{ij} \left( {\frac{{c^{3} }}{{p_{s} R_{j}^{2} }}} \right) \)

- \( S_{O} \) :

-

\( \frac{{\mu \omega_{j} LD}}{{W_{o} }}\left( {\frac{{R_{j} }}{c}} \right)^{2} \), Sommerfeld number

- \( \overline{t} \) :

-

\( t\left( {\frac{{c^{2} p_{s} }}{{\mu_{r} R_{j}^{2} }}} \right) \)

- \( \overline{T}_{f} \) :

-

\( T_{f} \left( {\frac{1}{{p_{s} cR_{j}^{2} }}} \right) \)

- \( \overline{\mu } \) :

-

\( \frac{\mu }{{\mu_{r} }} \)

- \( \overline{W}_{o} ,\overline{F}_{o} \) :

-

\( \left( {\frac{{W_{o} ,F_{o} }}{{p_{s} R_{j}^{2} }}} \right) \)

- \( \overline{X}_{j} ,\overline{Z}_{j} \) :

-

\( \left( {\frac{{X_{j} , Z_{j} }}{c}} \right) \)

- \( \lambda \) :

-

\( \frac{L}{D} \), Aspect ratio

- \( \overline{\tau } \) :

-

\( \tau \left( {\frac{{R_{j} }}{{p_{s} c}}} \right) \)

- \( \overline{z} \) :

-

\( \left( {\frac{z}{h}} \right) \), Coordinates across fluid film thickness

- \( \overline{{\dot{\gamma }}} \) :

-

\( \dot{\gamma }\left( {\frac{{\mu_{r} R_{j} }}{{p_{s} c}}} \right) \)

- \( {{\Omega }} \) :

-

\( \omega_{j} \left( {\frac{{\mu_{r} R_{j}^{2} }}{{c^{2} P_{s} }}} \right) \)

- \( \overline{\omega }_{th} \) :

-

\( \frac{{\omega_{th} }}{{\omega_{I} }} \)

- \( {{\Psi }} \) :

-

\( \frac{{k_{1} H}}{{c^{3} }} \), Permeability parameter

- \( \left[ {\overline{F}_{ij} } \right] \) :

-

Fluidity matrix

- \( N_{i} ,N_{j} \) :

-

Shape functions

- \( \left[ {\overline{P}_{j} } \right] \) :

-

Nodal pressure vector

- \( \left[ {\overline{Q}_{j} } \right] \) :

-

Nodal flow vector

- \( \left[ {\overline{R}_{Hj} } \right] \) :

-

RHS vector due to hydrodynamic terms

- \( \left[ {\overline{R}_{Xj} } \right] \) :

-

RHS vector due to squeeze velocity \( \left( {\overline{{\dot{X}}} } \right) \)

- \( \left[ {\overline{R}_{Zj} } \right] \) :

-

RHS vector due to squeeze velocity \( \left( {\overline{{\dot{Z}}} } \right) \)

- \( e \) :

-

eth Element

- j :

-

Journal

- \( o \) :

-

Steady-state condition

- \( - \) :

-

Nondimensional parameter

- \( min/max \) :

-

Minimum/Maximum value

- \( r \) :

-

Reference value

- /:

-

First/second derivative w.r.t, time

- s :

-

Supply

References

Morgan V, Cameron A (1957) Mechanism of lubrication in porous metal bearings. In: Proceedings of the conference on lubrication and wear, institution of mechanical engineers, London, pp 151–157

Lubrication, Group W, Cameron A, Morgan V, Stainsby A (1962) Critical conditions for hydrodynamic lubrication of porous metal bearings. Proc Inst Mech Eng 176(1):761–770

Rhodes C, Rouleau W (1965) Hydrodynamic lubrication of narrow porous metal bearings with sealed ends. Wear 8(6):474–486

Mokhtar M, Rafaat M, Shawki G (1984) Experimental investigations into the performance of porous journal bearings. SAE technical paper

Howarth R (1976) Externally pressurized porous thrust bearings. ASLE Trans 19(4):293–300

Chattopadhyay A, Majumdar B (1984) Steady state solution of finite hydrostatic porous oil journal bearings with tangential velocity slip. Tribol Int 17(6):317–323

Guha SK (1986) Study of conical whirl instability of externally pressurized porous oil journal bearings with tangential velocity slip. ASME J Tribol 108(2):256–261

Cusano C (1972) Lubrication of a two-layer porous journal bearing. J Mech Eng Sci 14(5):335–339

Cusano C (1972) Analytical investigation of an infinitely long, two-layer, porous bearing. Wear 22(1):59–67

Saha N, Majumdar B (2004) Steady-state and stability characteristics of hydrostatic two-layered porous oil journal bearings. Proc Inst Mech Eng Part J J Eng Tribol 218(2):99–108

Okano M (1993) Studies of externally pressurized porous gas bearings. Electrotechnical Laboratory, Researches (ISSN 0366-9106), no 952

Rao T, Rani A, Nagarajan T, Hashim F (2013) Analysis of journal bearing with double-layer porous lubricant film: influence of surface porous layer configuration. Tribol Trans 56(5):841–847

Srinivasan U (1977) The analysis of a double-layered porous slider bearing. Wear 42(2):205–215

Hashimoto H, Wada S, Nojima K (1986) Performance characteristics of worn journal bearings in both laminar and turbulent regimes. Part I: steady-state characteristics. ASLE Trans 29(4):565–571

Dufrane KF, Kannel JW, McCloskey TH (1983) Wear of steam turbine journal bearings at low operating speeds. ASME J Lubr Tech 105(3):313–317

Laurant F, Childs D (2002) Measurements of rotordynamic coefficients of hybrid bearings with (a) a plugged orifice, and (b) a worn land surface. J Eng Gas Turbines Power 124(2):363–368

Tokar I, Alexandrov S (1989) Solution of a hydrostatic problem in turbulent motion of lubricant with allowance for shaft deformation and bearing wear. Trenie Iznos 10(2):219–224

Kumar A, Mishra S (1996a) Steady state analysis of noncircular worn journal bearings in nonlaminar lubrication regimes. Tribol Int 29(6):493–498

Kumar A, Mishra S (1996b) Stability of a rigid rotor in turbulent hydrodynamic worn journal bearings. Wear 193(1):25–30

Awasthi R, Jain S, Sharma SC (2006) Finite element analysis of orifice-compensated multiple hole-entry worn hybrid journal bearing. Finite Elem Anal Des 42(14–15):1291–1303

Vaidyanathan K, Keith TG Jr (1989) Numerical prediction of cavitation in noncircular journal bearings. Tribol Trans 32(2):215–224

Buckholz RH (1986) Effects of power—law, non-newtonian lubricants on load capacity and friction for plane slider bearings. ASME. J. Tribol. 108(1):86–91

Safar Z (1979) Journal bearings operating with non-newtonian lubricant films. Wear 53(1):95–100

Tayal S, Sinhasan R, Singh D (1982) Finite element analysis of elliptical bearings lubricated by a non-Newtonian fluid. Wear 80(1):71–81

Tayal S, Sinhasan R, Singh D (1981) Analysis of hydrodynamic journal bearings with non-Newtonian power law lubricants by the finite element method. Wear 71(1):15–27

Prashad H (1988) The effects of viscosity and clearance on the performance of hydrodynamic journal bearings. Tribol Trans 31(2):303–309

Wu Z, Dareing DW (1994) Non-Newtonian effects of powder-lubricant slurries in hydrostatic and squeeze-film bearings. Tribol Trans 37(4):836–842

Sharma SC, Jain SC, Sinhasan R, Sah P (2001) Static and dynamic performance characteristics of orifice compensated hydrostatic flexible journal bearings with non-Newtonian lubricants. Tribol Trans 44(2):242–248

Khatri CB, Sharma SC (2016) Influence of textured surface on the performance of non-recessed hybrid journal bearing operating with non-Newtonian lubricant. Tribol Int 95:221–235

Phani Kumar M, Samanta P, Murmu N (2015) Rigid rotor stability analysis on finite hydrostatic double-layer porous oil journal bearing with velocity slip. Tribol Trans 58(5):930–940

Zhang G, Yin Y, Xue L, Zhu G, Tian M (2017) Effects of surface roughness and porous structure on the hydrodynamic lubrication of multi-layer oil bearing. Ind Lubr Tribol 69(4):455–463

Sinhasan R, Sharma S, Jain S (1989) Performance characteristics of an externally pressurized capillary-compensated flexible journal bearing. Tribol Int 22(4):283–293

Crosby W, Chetti B (2009) The static and dynamic characteristics of a two-lobe journal bearing lubricated with couple-stress fluid. Tribol Trans 52(2):262–268

Kumar A, Rao N (1993) Steady state performance of finite hydrodynamic porous journal bearings in turbulent regimes. Wear 167(2):121–126

Chen C-H, Kang Y, Huang C-C (2004) The influences of orifice restriction and journal eccentricity on the stability of the rigid rotor-hybrid bearing system. Tribol Int 37(3):227–234

Dowson D (1962) A generalized Reynolds equation for fluid-film lubrication. Int J Mech Sci 4(2):159–170

Gururajan K, Prakash J (2002) Roughness effects in a narrow porous journal bearing with arbitrary porous wall thickness. Int J Mech Sci 44(5):1003–1016

D’Agostino V, Ruggiero A, Senatore A (2009) Unsteady oil film forces in porous bearings: analysis of permeability effect on the rotor linear stability. Meccanica 44(2):207–214

Garg H, Kumar V, Sharda H (2010) Performance of slot-entry hybrid journal bearings considering combined influences of thermal effects and non-Newtonian behavior of lubricant. Tribol Int 43(8):1518–1531

Khatri CB, Sharma SC (2018) Analysis of textured multi-lobe non-recessed hybrid journal bearings with various restrictors. Int J Mech Sci 145:258–286

Sharma N, Kango S, Sharma R (2019) Adiabatic analysis of microtextured porous journal bearings functioned with power law fluid model. Proc Inst Mech Eng Part J J Eng Tribol 233(10):1541–1553

Fillon M, Bouyer J (2004) Thermohydrodynamic analysis of a worn plain journal bearing. Tribol Int 37(2):129–136

Naduvinamani N, Patil S (2009) Numerical solution of finite modified Reynolds equation for couple stress squeeze film lubrication of porous journal bearings. Comput Struct 87(21–22):1287–1295

Awasthi R, Sharma SC, Jain S (2007) Performance of worn non-recessed hole-entry hybrid journal bearings. Tribol Int 40(5):717–734

Nicodemus ER, Sharma SC (2010) Influence of wear on the performance of multirecess hydrostatic journal bearing operating with micropolar lubricant. J Tribol 132(2):021703

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, A., Sharma, S.C. Analysis of a double layer porous hybrid journal bearing considering the combined influence of wear and non-Newtonian behaviour of lubricant. Meccanica 56, 73–98 (2021). https://doi.org/10.1007/s11012-020-01259-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-020-01259-2