On the basis of data on the distribution of electric power in the working space of a furnace, resistances of the zones of charge, arc, and melt, and the characteristics of displacements of electrodes obtained with the help of an automated system of monitoring of the electric parameters of the process, we estimate the efficiency of the electric mode of a two-electrode single-phase furnace used for smelting commercial silicon. The influence of the methods and procedures used for the regulation of the conditions of charge dosing and landing of electrodes on the electric mode is investigated.

It is shown that the requirements of stabilization of the useful power and its rational distribution over the zones imposed on the regulation of the electric mode are not satisfied. The instability of the useful power of the furnace is caused by the application of the manual mode of control and the errors of measurements of currents in the electrodes caused by the incorrect calibration of the reference ammeter. The realization of the technological process under the conditions of high landing of electrodes does not correspond to the rational values of the energy efficiency of the furnace and is accompanied by significant losses of the arc power of the furnace and silicon in the form of silicon monoxide.

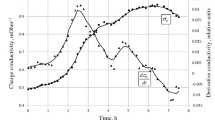

The absence of data on the state of the working space of the furnace does not enable us to control the distribution of power over its main zones and to realize the possibility of full control over the process. We present examples that confirm the oscillating nature of the technological process and significant asymmetry of the useful power of separated electrodes. It is shown that numerous violations in the course of the analyzed process are caused by the use of irrational methods and procedures of regulation of the modes of charge dosing and landing of electrodes. In particular, the alternation of the modes of loading of the charge with excess and lack of carbon leads to significant fluctuations in the useful power of the furnace and the powers of the arcs. Moreover, the course of smelting can be described as a permanent transient process from one extremely inefficient state into another.

Similar content being viewed by others

References

V. P. Vorob’ev, Electrothermy of Reduction Processes [in Russian], Ural Branch of the Russian Academy of Sciences, Ekaterinburg (2009).

O. V. Zayakin, V. I. Zhuchkov, and L. I. Leont’ev, “Electric furnace bath structure during high-chromium ferrochrome production,” Metallurg, 62, No. 6, 14–19 (2018); English translation: Metallurgist, 62, Nos. 5–6, 493–500 (2918).

K. S. Elkin, V. Ya. Svishchenko, A. A. Molyavko, and D. V. Dresvyanskii, “Electric mode of furnaces under the conditions of disbalance of active power over the electrodes in a furnace bath,” in: Proc. of the 10th Internat. Congress and Exhibition “Nonferrous Metals and Minerals” [in Russian], Krasnoyarsk (2018), pp. 1059–1064.

V. P. Vorob’ev and A. V. Ignat’ev, “Numerical analysis of basic electric and geometric parameters of ore-thermal electric furnaces (OTEF) in the production of silicon alloys,” Électrometallurgiya, No. 6, 31–35 (2012).

V. S. Cherednichenko, R. A. Bikeev, M. V. Cherednichenko, and M. G. Kuz’min, “Power transfer between the phases of current leads in the electric arc furnaces,” Électrometallurgiya, No. 4, 11–19 (2016).

V. S. Cherednichenko, R. A. Bikeev, and M. V. Cherednichenko, “Investigation of the power transfer between the phases of current leads in the electric arc furnaces with the use of mathematical models,” Électrometallurgiya, No. 6, 31–40 (2016).

G. V. Zeveke, P. A. Ionkin, A. V. Netushil, and S. V. Strakhov, Fundamentals of the Theory of Circuits [in Russian], Énergoatomizdat, Moscow (1989).

V. V. Godyna, V. Ya. Svishenko, and M. S. Lednev, “Automation of the technological processes in the production of ferroalloys,” in: Collection of Scientific Works “Improvement of the Technology and Equipment in the Production of Silicon and Silicon Ferroalloys” [in Russian], Rusal Engineering and Technology Center LLC, Krasnoyarsk (2012), pp. 82–92.

G. Sævarsdottir and J. A. Bakken, “Current distribution in submerged arc furnaces for silicon metal,” in: Proc. of the 12th Internat. Ferro-Alloys Congress, INFACON-12 (June 6–9, 2010, Helsinki, Finland), Helsinki (2010), pp. 717–728.

G. A. Sævarsdottir, M. T. Jonsson, and J. A. Bakken, “Arc-electrode interactions in silicon and ferrosilicon furnaces,” in: Proc. of the 10th Internat. Ferro-Alloys Congr., INFACON-10 (February 3–6, 2004, Cape Town, South Africa), Cape Town (2004), pp. 593–604.

G. A. Sævarsdottir, J. A. Bakken, V. G. Sevastyanenko, and L. Gu, “Arc simulation model for three-phase electro-metallurgical furnaces,” in: Proc. of the 9th Internat. Ferro-Alloys Congress, INFACON-9 (June 3–6, 2001, Quebec City, Canada), Quebec City (2001), pp. 253–263.

A. V. Sivtsov, M. M. Tsimbalist, V. I. Fadeev, Y. I. Ostrovskii, I. A. Veselovskii, and V. I. Afanas’ev, “Method of controlling the charge feeding condition in melting of ferrosilicium and ferrosilicochromium,” Russ. Metall., No. 12,1036–1040 (2012).

A. V. Sivtsov, V. P. Vorob’ev, and V. A. Pan’kov, “Rational automated control over the processes running in electric furnaces. I. Low-shaft electric furnaces for the production of ferroalloys as objects of control,” Électrometallurgiya, No. 8–16 (2017).

A. V. Sivtsov, K. S. Elkin, I. M. Kashlev, and A. I. Karlina, “Processes in the charge and hearth zones of the working space of the furnace and the problems of control over the conditions of charge dosing mode in the course of smelting of commercial silicon and high-silicon ferroalloys,” Metallurg, No. 5, 21–27 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 9, pp. 64–70, September, 2020.

Rights and permissions

About this article

Cite this article

Sivtsov, A.V., Elkin, K.S., Pan’kov, V.A. et al. Specific Features of the Electric Mode of the Technological Process of Smelting of Commercial Silicon. Metallurgist 64, 923–930 (2021). https://doi.org/10.1007/s11015-021-01073-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01073-5