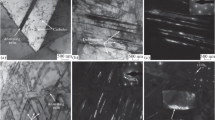

This work is devoted to studying the possibility of forming a graded structure in 08Kh18N10T stainless austenitic steel using radial-shear rolling. Experimental studies show that an ultrafine-grained structure extends into the bar from its surface to a depth of at least a quarter of the bar radius. A transition zone is located in the area between 0.5R and 0.25R of the bar cross section. Due to structural heterogeneity in the bar cross section there is an increase in microhardness by more than a factor of two from the initial value of 152 to 320HV in surface layers and a smooth drop by 10.2% in microhardness within the central area of a bar. This points to a graded nature of the structure formed in the bars of 08X18N10T steel after radial-shear rolling. A study of mechanical properties shows an increase in the tensile strength by about a factor of two to 938 MPa and a reduction in elongation to 24% in the peripheral zone and to 19% in the axial zone.

Similar content being viewed by others

References

R. Z. Valiev, R. K. Islamgaliev, and I. V. Alexandrov, “Bulk nanostructured materials from severe plastic deformation,” Progress in Materials Science, 45, No. 2, 103–189 (2000).

C. Xu, Z. Horita, and T. G. Langdon, “The evolution of homogeneity in processing by high-pressure torsion,” Acta Materialia, 55, No. 1, 203–212 (2007).

I. E. Volokitina, A. V. Volokitin, A. B. Naizabelov, and S. N. Lezhnev, “Change in structure and mechanical properties of aluminum A0 during implementation of a combined method of radial-shear rolling deformation,” Metallurg, No. 9, 85–89 (2019).

O. P. Maksimkin, M. N. Gusev, K. B. Tsai, A. V. Yarovchuk, O. V. Rybal’chenko, N. A, Enikeev, R. Z. Valiev, and S. V. Dobatkin, “Effect of neutron radiation on the microstructure, mechanical and corrosion properties of ultrafine-grained stainless chromiumnickel steel,” Fiz. Metall. Metallovedenie, 116, No. 12, 1330–1338 (2015).

A. B. Naizabekov and I. E. Volokitina, “Effect of original structural state of heat-resistant Cr-M0-steel on mechanical properties after equal-channel angular extrusion,” Fiz. Metall. Metallovedenie, 120, No. 2, 190–197 (2019).

M. Yu. Murashkin, I. Sabirov, V. U. Kazykhanov, E. V. Bobruk, A. A. Dubravina, and R. Z. Valiev, “Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al alloy processed via ECAP-PC,” J. Mater. Science, 48, (13), 4501–4509 (2013).

T. H. Fang, W. L. Li, N. R. Tao, and K. Lu, “Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper,” Science, 331 (6024), 1587–1590 (2011).

G. I. Raab, L. A. Simonova, and G. N. Alyoshin, “Tailoring the gradient ultrafine-grained structure in low-carbon steel during drawing with shear,” Metallurgiya, 55, No. 2, 177–180 (2016).

S. Ishkina, B. Kuhfuss, and C. Schenck, “Influence of the relative rotational speed on component features in micro rotary swaging,” MATEC Web of Conferences, 21, 09012 (2015).

S. P. Galkin, “Technology and radial-shear rolling mini mill – optimum for creating safe production,” Stal’, No. 1, 39–42 (2-14).

V. A. Sheremet’ev, A. A. Kudryashova, Suan Ta Din, S. P. Galkin, S. D. Prokoshkin, and V. Brailovskii, “Promising technology for preparing bars of superelastic alloy Ti–Zr–Nb for medicinal purposes based on a combination of radial-shear rolling and rotational forging,” Metallurg, No. 1, 45–52 (2019).

Y. L. Wang, A. Molotnikov, M. Diez, R. Lapovok, H.-E. Kim, J. Tao Wang, and Y. Estrin, “Gradient structure produced by three roll planetary milling: Numerical simulation and microstructural observations,” Mater. Science and Eng. A, 639, 165–172 (2015).

S. Dobatkin, S. Galkin, Y. Estri, V. Serebryany, M. Diez, N. Martynenko, F. Lukyanova, and V. Perezhogin, “Grain refinement, texture, and mechanical properties of a magnesium alloy after radial-shear rolling,” J. of Alloys and Compounds, 774, 969–979 (2019).

D. A. Negodin, S. P. Galkin, E. A. Kharitonov, B. V. Karpov, D. N. Khar’kovskii, I. A. Dubovistkaya, and P. V. Patrin, “Testing radial-shear rolling technology and preplanning selection of mini-mills for bending small section titanium bar product under AO ChMZ conditions,” Metallurg, No. 11, 4–46 (2018).

S. P. Galkin, RF Patent 2293619 C1. Screw Rolling Method. 04.04.2006; Publ. 02.20.2007. Bull. No. 5.

S. P. Galkin, “Deformed metal movement trajectory as a basis for controlling radial-shear and screw rolling,” Stal’, No. 7, 63–66 (2004).

R. Z. Valiev, I. V. Alexandrov, Y. T. Zhu, and T. C. Lowe, “Paradox of strength and ductility in metals processed by severe plastic deformation,” J. Mater. Research, 17, No. 1, 5–8 (2002).

S. P. Galkin, B. A. Romantsev, and E. A. Kharitonov, “Putting into practice innovative potential in the universal radial-shear rolling process,” CIS Iron and Steel Review, 9, No. 1, 35–39 (2014).

N. S. Surikova, I. V. Vlasov, N. A. Narkevich, A. I. Gordienko, and P. V. Kuznetsov, “Structure and deformation properties of austenitic stainless steel,” Fiz. Metall. Metallovedenie, 121, No. 3, 314–321 (2020).

S. Lezhnev, A. Naizabekov, and I. Volokitina, “Features of change of the structure and mechanical properties of steel at ECAP depending on the initial state,” J. Chem. Technology and Metallurgy, 52, No. 4, 626–635 (2017).

K. Tsay, A. Arbuz, N. Gusseynov, R. Nemkaeva, N. Ospanov, and I. Krupenkin, “Refinement of the microstructure of steel by cross rolling,” J. Chem. Technology and Metallurgy, 51, No. 4, 385–392 (2016).

A. Naizabekov, A. Arbuz, S. Lezhnev, E. Panin, and I. Volokitina, “The development and testing of a new method of qualitative analysis of the microstructure quality, for example of steel AISI 321 subjected to radial shear rolling,” Physica Scripta, 94, No. 10105702 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 11, pp. 46–54, November, 2020.

Rights and permissions

About this article

Cite this article

Lezhnev, S.N., Naizabekov, A.B., Panin, E.A. et al. Graded Microstructure Preparation in Austenitic Stainless Steel during Radial-Shear Rolling. Metallurgist 64, 1150–1159 (2021). https://doi.org/10.1007/s11015-021-01100-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01100-5