Abstract

This article is devoted to the analysis of the influence of the joint clearances in a mechanism of a circuit breaker, which is a 42 degree-of-freedom mechanism made of seven links, seven revolute joints, and four unilateral contacts with friction. Spatial (3D) revolute joints are modeled with both radial and axial clearances taking into account contact with flanges. Unilateral contact, Coulomb’s friction and Newton impact laws are modeled within the framework of nonsmooth mechanics without resorting to some regularizations or compliance/damping at contact. The nonsmooth contact dynamics method based on an event-capturing time-stepping scheme with a second order cone complementarity solver is used to perform the numerical integration. Furthermore, the stabilization of the constraints at the position level is made thanks to the stabilized combined projected Moreau–Jean scheme. The nonsmooth modeling approach together with an event–capturing time-stepping scheme allows us to simulate, in an efficient and robust way, the contact and impacts phenomena that occur in joints with clearances. In particular, comparing with the event-detecting time-stepping schemes, the event-capturing scheme enables us to perform the time-integration with a large number of events (impacts, sliding/sticking transitions, changes in the direction of sliding) and possibly with finite-time accumulations with a reasonable time-step length. Comparing with compliant contact models, we avoid stiff problems related with high stiffnesses at contact which generate some issues in contact stabilization and spurious oscillations during persistent contact periods. In the studied mechanisms of the circuit breakers, the numerical method deals with more than 70 contact points without any problems. Furthermore, the number of contact parameters is small—one coefficient of restitution and one coefficient of friction. Though they are sometimes difficult to measure accurately, the sensitivity of the simulation result with respect to contact parameters is low in the mechanism of the circuit breaker. It is demonstrated that this method, thanks to its robustness and efficiency, allows us to perform a sensitivity analysis using a Monte Carlo method. The numerical results are also validated by careful comparisons with experimental data, showing a very good correlation.

Similar content being viewed by others

Notes

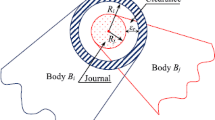

The polarization effect is created by two aspects, the presence of radial clearance in the revolute joint and the forces acting on the parts.

Definition 1 Polarization is the contact position between the two parts under the influence of an external force in an equilibrium stage.

To provide an example: a commercial software such as ls-dyna (which is based on a compliant method) takes around six to eight hours to simulate the C-60 breaker mechanism with clearance in the revolute joints on a standard desktop computer.

When friction is present during impacts, there is in general no reason that \(e_{r}\) should be upper bounded by 1, see [11, Chap. 4].

A control device that utilizes a solenoid to open a circuit breaker.

Under normal working condition, the plunger is held in a position by the spring because the magnetic field generated by the coil is not sufficient to release the latch. When a fault current flows, the magnetic field generated by the coil is sufficient to overcome the spring force holding the plunger in position. And hence the plunger moves and then actuates the tripping mechanism.

One of the great advantages of the NSCD method is precisely the possibility to allow a drastic decrease of the simulation time (while keeping very good predictability), hence making it possible to run a Monte Carlo method with several thousands of simulations.

Parts-Per-Million is the fraction of a quantity per one million parts.

See Definition 1.

References

Abadie, M.: Dynamic simulation of rigid bodies: modelling of frictional contact. In: Brogliato, B. (ed.) Impacts in Mechanical Systems: Analysis and Modelling. Lecture Notes in Physics (LNP), vol. 551, pp. 61–144. Springer, Berlin (2000)

Acary, V.: Projected event-capturing time-stepping schemes for nonsmooth mechanical systems with unilateral contact and Coulomb’s friction. Comput. Methods Appl. Mech. Eng. 256, 224–250 (2013)

Acary, V., Bonnefon, O., Brémond, M., Huber, O., Pérignon, F., Sinclair, S.: SICONOS: a software for the modeling, the simulation and the control of nonsmooth dynamical systems, 2005–2016. http://siconos.gforge.inria.fr

Acary, V., Brogliato, B.: Numerical Methods for Nonsmooth Dynamical Systems. Applications in Mechanics and Electronics. Lecture Notes in Applied and Computational Mechanics, vol. 35. Springer, Berlin/Heidelberg (2008)

Acary, V., Cadoux, F.: Applications of an Existence Result for the Coulomb Friction Problem. In: Stavroulakis, G.E. (ed.) Recent Advances in Contact Mechanics. Lecture Notes in Applied and Computational, vol. 56. Springer, Berlin (2013)

Acary, V., Cadoux, F., Lemaréchal, C., Malick, J.: A formulation of the linear discrete Coulomb friction problem via convex optimization. Z. Angew. Math. Mech. 91(2), 155–175 (2011)

Acary, V., Pérignon, F.: An introduction to SICONOS. Technical Report RT-0340, INRIA (2007)

Akhadkar, N., Acary, V., Brogliato, B.: Analysis of collocated feedback controllers for four-bar planar mechanisms with joint clearances. Multibody Syst. Dyn. 38(2), 101–136 (2016)

Bauchau, O.A., Rodriguez, J.: Modeling of joints with clearance in flexible multibody systems. Int. J. Solids Struct. 39(1), 41–63 (2002)

Ben Abdallah, M.A., Khemili, I., Aifaoui, N.: Numerical investigation of a flexible slider–crank mechanism with multijoints with clearance. Multibody Syst. Dyn. 38(2), 173–199 (2016)

Brogliato, B.: Nonsmooth Mechanics: Models, Dynamics and Control, 3rd edn. Springer, Switzerland (2016)

Brüls, O., Acary, V., Cardona, A.: Simultaneous enforcement of constraints at position and velocity levels in the nonsmooth generalized-\(\alpha\) scheme. Comput. Methods Appl. Mech. Eng. 281, 131–161 (2014)

Brutti, C., Coglitore, G., Valentini, P.P.: Modeling 3D revolute joint with clearance and contact stiffness. Nonlinear Dyn. 66(4), 531–548 (2011)

Chase, K.W., Greenwood, W.H.: Design issues in mechanical tolerance analysis. Manuf. Rev. 1(1), 50–59 (1988)

Chase, K.W., Parkinson, A.R.: A survey of research in the application of tolerance analysis to the design of mechanical assemblies. Res. Eng. Des. 3(1), 23–37 (1991)

Chen, Y., Su, Y., Chen, C.: Dynamic analysis of a planar slider-crank mechanism with clearance for a high speed and heavy load press system. Mech. Mach. Theory 98, 81–100 (2016)

OpenCascade Corp.: (2016). http://www.opencascade.org

Dantan, J.Y., Qureshi, A.J.: Worst-case and statistical tolerance analysis based on quantified constraint satisfaction problems and Monte Carlo simulation. Comput. Aided Des. 41(1), 1–12 (2009)

Association Francaise de Normalisation. NFT58000 Plastics—tolerances applicable to moulded plastic parts (1987)

De Saxcé, G.: Une généralisation de l’inégalité de Fenchel et ses applications aux lois constitutives. C. R. Acad. Sci., Sér. 2, Méc. Phys. Chim. Astron. 314, 125–129 (1992)

Deck, J.F., Dubowsky, S.: On the limitations of predictions of the dynamic response of machines with clearance connections. J. Mech. Des. 116(3), 833–841 (1994)

Dhande, S.G., Chakraborty, J.: Mechanical error analysis of spatial linkages. J. Mech. Des. 100(4), 732–738 (1978)

Dubowsky, S., Deck, J.F., Costello, H.: The dynamic modeling of flexible spatial machine systems with clearance connections. J. Mech. Transm. Autom. 109(1), 87–94 (1987)

Flores, P.: A parametric study on the dynamic response of planar multibody systems with multiple clearance joints. Nonlinear Dyn. 61(4), 633–653 (2010)

Flores, P., Ambrósio, J.: Revolute joints with clearance in multibody systems. Comput. Struct. 82(17), 1359–1369 (2004)

Flores, P., Ambrósio, J., Claro, J.P.: Dynamic analysis for planar multibody mechanical systems with lubricated joints. Multibody Syst. Dyn. 12(1), 47–74 (2004)

Flores, P., Leine, R., Glocker, C.: Modeling and analysis of planar rigid multibody systems with translational clearance joints based on the non-smooth dynamics approach. Multibody Syst. Dyn. 23, 165–190 (2010)

Garrett, R.E., Hall, A.S.: Effect of tolerance and clearance in linkage design. J. Manuf. Sci. Eng. 91(1), 198–202 (1969)

Greenwood, W.H., Chase, K.W.: Worst case tolerance analysis with nonlinear problems. J. Manuf. Sci. Eng. 110(3), 232–235 (1988)

Gummer, A., Sauer, B.: Influence of contact geometry on local friction energy and stiffness of revolute joints. J. Tribol. 134(2), 021402 (2012)

Gummer, A., Sauer, B.: Modeling planar slider-crank mechanisms with clearance joints in RecurDyn. Multibody Syst. Dyn. 31, 127–145 (2014)

Haroun, A.F., Megahed, S.M.: Simulation and experimentation of multibody mechanical systems with clearance revolute joints. In: Proceedings of World Academy of Science, Engineering and Technology. (2012). World Academy of Science, Engineering and Technology

Huang, X., Zhang, Y.: Robust tolerance design for function generation mechanisms with joint clearances. Mech. Mach. Theory 45(9), 1286–1297 (2010)

Jean, M.: The non-smooth contact dynamics method. Comput. Methods Appl. Mech. Eng. 177(3), 235–257 (1999)

Jean, M., Moreau, J.J.: Dynamics in the presence of unilateral contacts and dry friction: a numerical approach. In: del Piero, G., Maceri, F. (eds.) Unilateral Problems in Structural Analysis II. CISM Courses and Lectures, vol. 304, pp. 151–196. Springer, Berlin (1987)

Jeang, A.: Tolerance design: choosing optimal tolerance specifications in the design of machined parts. Qual. Reliab. Eng. Int. 10(1), 27–35 (1994)

Kakizaki, T., Deck, J.F., Dubowsky, S.: Modeling the spatial dynamics of robotic manipulators with flexible links and joint clearances. J. Mech. Des. 115(4), 839–847 (1993)

Kane, V.E.: Process capability indices. J. Qual. Technol. 18(1), 41–52 (1986)

Kotz, S., Johnson, N.L.: Process Capability Indices. CRC Press, Boca Raton (1993)

Krinner, A., Thümmel, T.: Non-smooth behaviour of a linkage mechanism with revolute clearance joints. In: New Advances in Mechanisms, Transmissions and Applications, pp. 233–241. Springer, Berlin (2014)

Lampaert, V., Swevers, J., Al-Bender, F.: Modification of the Leuven friction model structure. IEEE Trans. Autom. Control 47(4), 683–687 (2002)

Lankarani, H.M., Nikravesh, P.E.: Continuous contact force models for impact analysis in multibody systems. Nonlinear Dyn. 5(2), 193–207 (1994)

Lemaréchal, C.: Using a modulopt minimization code. Unpublished Technical Note, INRIA Rocquencourt (1980). http://people.sc.fsu.edu/~inavon/5420a/modulopt.pdf

Lemaréchal, C., Panier, E.: Les modules M2QN1 et MQHESS. Unpublished Technical Note, INRIA Rocquencourt (1983). https://who.rocq.inria.fr/Jean-Charles.Gilbert/modulopt/optimization-routines/m2qn1/m2qn1.pdf

Liu, C., Tian, Q., Hu, H.: Dynamics and control of a spatial rigid-flexible multibody system with multiple cylindrical clearance joints. Mech. Mach. Theory 52, 106–129 (2012)

Liu, C., Zhang, K., Yang, L.: The compliance contact model of cylindrical joints with clearances. Acta Mech. Sin. 21(5), 451–458 (2005)

Marques, F., Isaac, F., Dourado, N., Flores, P.: An enhanced formulation to model spatial revolute joints with radial and axial clearances. Mech. Mach. Theory 116, 123–144 (2017)

Moreau, J.J.: Unilateral contact and dry friction in finite freedom dynamics. In: Moreau, J.J., Panagiotopoulos, P.D. (eds.) Nonsmooth Mechanics and Applications. CISM, Courses and Lectures, vol. 302, pp. 1–82. Springer, Wien/New York (1988)

Moreau, J.J.: Some numerical methods in multibody dynamics: Application to granular materials. Eur. J. Mech /A. Solids suppl. (13), 93–114 (1994)

Moreau, J.J.: Numerical aspects of the sweeping process. Comput. Methods Appl. Mech. Eng. 177, 329–349 (1999)

Nigam, S.D., Turner, J.U.: Review of statistical approaches to tolerance analysis. Comput. Aided Des. 27(1), 6–15 (1995)

Orden, J.C.G.: Analysis of joint clearances in multibody systems. Multibody Syst. Dyn. 13(4), 401–420 (2005)

Pereira, C., Ramalho, A., Ambrosio, J.: An enhanced cylindrical contact force model. Multibody Syst. Dyn. 35(3), 277–298 (2015)

Pereira, C.M., Ramalho, A.R., Ambrosio, J.: A critical overview of internal and external cylinder contact force models. Nonlinear Dyn. 63, 681–697 (2011)

Pereira, C.M., Ramalho, A.R., Ambrosio, J.: An enhanced cylindrical contact force model. Multibody Syst. Dyn. 35(3), 277–298 (2015)

PythonOCC: 3D CAD/CAE/PLM development framework for the Python programming language (2016). http://www.pythonocc.org

Salahshoor, E., Ebrahimi, S., Maasoomi, M.: Nonlinear vibration analysis of mechanical systems with multiple joint clearances using the method of multiple scales. Mech. Mach. Theory 105, 495–509 (2016)

Scholz, F.: Tolerance stack analysis methods. In: Research and Technology Boeing Information & Support Services, Boeing, Seattle, pp. 1–44 (1995)

Skowronski, V.J., Turner, J.U.: Using Monte-Carlo variance reduction in statistical tolerance synthesis. Comput. Aided Des. 29(1), 63–69 (1997)

Srinivasan, V.: ISO deliberates statistical tolerancing. In: Geometric Design Tolerancing: Theories, Standards and Applications, pp. 77–87. Springer, Berlin (1998)

Studer, C.: Numerics of Unilateral Contacts and Friction. Modeling and Numerical Time Integration in Non-Smooth Dynamics. Lecture Notes in Applied and Computational Mechanics, vol. 47. Springer, Berlin (2009)

Yan, S., Xiang, W., Zhang, L.: A comprehensive model for 3D revolute joints with clearances in mechanical systems. Nonlinear Dyn. 80(1), 309–328 (2015)

Thümmel, T., Funk, K.: Multibody modelling of linkage mechanisms including friction, clearance and impact. In: Proceedings of the 10th World Congress on the Theory of Machines and Mechanisms in Oulu, June 20–24, vol. 4, pp. 1387–1392. Oulu University Press, Finland (1999)

Thomopoulos, N.T.: Essentials of Monte Carlo Simulation: Statistical Methods for Building Simulation Models. Springer, New York (2012)

Thümmel, T.: Experimentelle Mechanismen Dynamik: Messung, Modellierung, Simulation, Verifikation, Interpretation und Beeinflussung typischer Schwingungsphänomene an einem Mechanismenprüfstand. PhD thesis, München, Technische Universität München, Habil.-Schr. (2012)

Thümmel, T., Ginzinger, L.: Measurements and simulations of a crank and rocker mechanism including friction, clearance and impacts. In: Proceedings of the IX. International Conference on the Theory of Machines and Mechanisms in Liberec/Czech Republic, Aug. 31–Sept. 2, 2004, pp. 763–768 (2004). Technical University of Liberec, Department of Textile Machine Design

Thümmel, T., Roßner, M.: Introduction to modelling and parameter identification methodology of linkages by measurements and simulation. In: Proceedings of the 13th World Congress in Mechanism and Machine Science, Guanajuato, Mexico, 19–25 June, vol. IMD–123 (2011)

Thümmel, T., Rutzmoser, J., Ulbrich, H., Robner, M.: Friction modeling and parameter value estimation of mechanisms. In: The 2nd Joint International Conference on Multibody Systems Dynamics, Stuttgart, Germany, May 29–June 1, 2012, pp. 302–312 (2012). University of Stuttgart, Institute of Engineering and Computational Mechanics

Tian, Q., Liu, C., Machado, M., Flores, P.: A new model for dry and lubricated cylindrical joints with clearance in spatial flexible multibody systems. Nonlinear Dyn. 64(1), 25–47 (2011)

Tian, Q., Lou, J., Mikkola, A.: A new elastohydrodynamic lubricated spherical joint model for rigid-flexible multibody dynamics. Mech. Mach. Theory 107, 210–228 (2017)

Tian, Q., Xiao, Q., Sun, Y., Hu, H., Liu, H., Flores, P.: Coupling dynamics of a geared multibody system supported by elastohydrodynamic lubricated cylindrical joints. Multibody Syst. Dyn. 33(3), 259–284 (2015)

Turner, J.U., Wozny, M.J.: Tolerances in computer-aided geometric design. Vis. Comput. 3(4), 214–226 (1987)

Virlez, G., Brüls, O., Tromme, E., Duysinx, P.: Modeling joints with clearance and friction in multibody dynamic simulation of automotive differentials. Theor. Appl. Mech. Lett. 3(1), 013003 (2013)

Wojtyra, M.: Modeling of static friction in closed-loop kinematic chains—uniqueness and parametric sensitivity problems. Multibody Syst. Dyn. 39(4), 337–361 (2017)

Wu, F., Dantan, J.Y., Etienne, A., Siadat, A., Martin, P.: Improved algorithm for tolerance allocation based on Monte Carlo simulation and discrete optimization. Comput. Ind. Eng. 56(4), 1402–1413 (2009)

Yaqubi, S., Dardel, M., Mohammadi Daniali, H., Hassan Ghasemi, M.: Modeling and control of crank-slider mechanism with multiple clearance joints. Multibody Syst. Dyn. 36(2), 143–167 (2016)

Zhang, C., Luo, J., Wang, B.: Statistical tolerance synthesis using distribution function zones. Int. J. Prod. Res. 37(17), 3995–4006 (1999)

Zhang, C.C., Wang, H-P.B.: Robust design of assembly and machining tolerance allocations. IIE Trans. 30(1), 17–29 (1997)

Zhang, Z., Xu, L., Flores, P., Lankarani, H.M.: A Kriging Model for dynamics of mechanical systems with revolute joint clearances. J. Comput. Nonlinear Dyn. 9(3), 031013 (2014)

Author information

Authors and Affiliations

Corresponding author

Appendix A: Process capability and performance indices

Appendix A: Process capability and performance indices

If worst-case tolerances are specified for the inputs, a worst-case tolerance can be calculated for the output. Let us denote the output by \(Y\) and the inputs by \(X_{i}, i\in (1,\dots,n)\). We consider \(Y = f(X_{i})\) and that the inputs have worst-case tolerances \(N_{Xi}\pm T_{Xi}\). Then the resulting worst-case tolerance for \(Y\) is denoted as \(N_{Y}\pm T_{Y}\). The lower specification limit (LSL), the upper specification limit (USL), nominal (\(N\)), and the tolerance are calculated as:

The most common way of denoting the statistical tolerance is \(N_{X}\pm T_{X}^{\langle ST\rangle}\). The statistical tolerance is always associated with a mean value (\(\bar {m}\)) and standard deviation (\(\sigma\)). The tolerance range is given as \(T_{X}=3\sigma\). The statistical tolerances are more restrictive. They further require that the process capability (\(C_{p}\)) and process capability index (\(C_{pk}\)) are centered for a good process [38, 39, 60].

Process capability (\(C_{p}\))

It evaluates the tolerance range (TR) compared to a standard six-sigma (\(6\sigma\)) production dispersion (see Fig. 22(a)). \(C_{p}\) measures how close a process is running to its specification limits relative to the natural variability of the process (normally it is given by \(6\sigma\)):

Process capability index (\(C_{pk}\))

It evaluates if the specification can be met given the process spread and tool shift from nominal. In other words, \(C_{pk}\) is the capability of the process to see whether or not the mean is centered between the specification limits (see Figs. 22(b) and 23(a)–(b)):

where \(\bar{m}\) is the mean value. An index of absolute centering \(C_{c}\) quantifies the shift of the mean from the nominal value, see Fig. 23(a)–(b). It is written as a ratio

Rights and permissions

About this article

Cite this article

Akhadkar, N., Acary, V. & Brogliato, B. Multibody systems with 3D revolute joints with clearances: an industrial case study with an experimental validation. Multibody Syst Dyn 42, 249–282 (2018). https://doi.org/10.1007/s11044-017-9584-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11044-017-9584-5