Abstract

Time-varying mesh stiffness is one of the main excitation sources of a gear system, and it is also considered as an important factor for the vibration and noise of gears. Thus, this excitation is usually taken as an input into the gear dynamic model to obtain the system dynamic responses. However, the mesh stiffness of a gear pair is actually nonlinear with respect to the dynamic mesh force (DMF) that fluctuates during the operation of gears. Therefore, the dynamic model of gears with the quasi-static mesh stiffness calculated under a constant load is not accurate sufficiently. In this paper, a dynamic model of spur gear is established with considering the effect of the force-dependent time-varying mesh stiffness, backlash and profile deviation. Due to the nonlinear relationship between the mesh stiffness and the load for each tooth pair, it needs first to determine the load sharing among tooth pairs and then calculate the overall mesh stiffness of the gear pair. As the mesh stiffness and DMF are related, the mesh stiffness is no longer directly taken into the gear dynamic model as an input, but is jointly solved with the numerical integration process using the gear dynamic model. Finally, the dynamic responses predicted from the established gear dynamic model are compared with the experimental results for validation and compared with the traditional models to reveal their differences. The results indicate that the established dynamic model of spur gear transmission has a wider application range than the traditional models.

Similar content being viewed by others

Abbreviations

- \(\delta _{\mathrm{b}}\), \(\delta _{\mathrm{s}}\), \(\delta _{\mathrm{a}}\) :

-

Bending deformation, shear deformation, axial deformation

- \(\alpha _{1}\) :

-

Angle between the line of action and the line perpendicular to the center line of the tooth

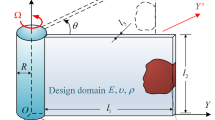

- x, l, d :

-

Defined in Fig. 1

- h :

-

Distance from the point of contact to the center line of the tooth

- E :

-

Young’s modulus

- v :

-

Poisson’s ratio

- W :

-

Tooth width

- \(I_{x},\,A_{x}\) :

-

Moment of inertia and the area of section at the distance x from the base along the tooth center line

- \(k_{\mathrm{b}},\, k_{\mathrm{s}},\, k_{\mathrm{a}}\) :

-

Bending stiffness, shearing stiffness, axial stiffness

- \(\delta _{\mathrm{f}}\) :

-

Additional deformation of the tooth caused gear body

- \(k_{\mathrm{f}}\) :

-

The stiffness related to the additional deformation of gear body

- L*,M*,P*,Q*:

-

Coefficients expressing the additional deformation of the tooth

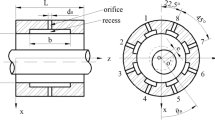

- \(S_{\mathrm{f}}\) :

-

Defined in Fig. 2

- \(\delta _{\mathrm{h}}\) :

-

Local contact compliance

- b :

-

Half width of the contact region on the tooth

- \(r_{\mathrm{p}},r_{\mathrm{g}}\) :

-

Radius of curvature at the point of contact of gear and pinion

- \(v_{\mathrm{p}},\,v_{\mathrm{g}}\) :

-

Poisson’s ratio of pinion and gear

- \(E_{\mathrm{p}},\,E_{\mathrm{g}}\) :

-

Young’s modulus of pinion and gear

- \(h_{x\mathrm{p}},h_{x{\mathrm{g}}}\) :

-

Distance from the point of contact to the center line of the tooth of the gear and pinion along the line of action direction

- \(k_{{\mathrm{h}}}{[F]}\) :

-

Local contact stiffness of tooth pair under load F

- \(J_{\mathrm{p}},J_{\mathrm{g}}\) :

-

Mass moments of inertia of pinion and gear

- \(K_{\mathrm{s}}{[F]}\) :

-

Mesh stiffness of single tooth pair under the load F

- K[F]:

-

The overall mesh stiffness of mesh gears under the load F

- \(k_{\mathrm{l}}\) :

-

Load-independent stiffness including bending, shear, axial stiffness and additional stiffness caused by gear body

- \(k_{\mathrm{l}i}\) :

-

Load-independent stiffness of tooth pair i

- \(k_{{\mathrm{h}}i}{[F]}\) :

-

The local contact stiffness of tooth pair i

- \(\delta \) :

-

Total deformation of the tooth at the contact point

- \(e_{i}\) :

-

Initial separation of the potential contact tooth pair i

- \(E_{i\mathrm{p}},E_{i\mathrm{p}}\) :

-

Profile error of tooth pair i of pinion and gear

- \(\eta _{i\mathrm{p}},\,\eta _{i\mathrm{g}}\) :

-

Profile modification of tooth pair \(i\_\) of pinion and gear

- \(\lambda _{\mathrm{p}},\,\lambda _{\mathrm{g}}\) :

-

Eccentricity error of pinion and gear

- \(\delta _{i}\) :

-

Deformation of the tooth pair i

- \(F_{i}\) :

-

Load on the tooth pair i

- \(\hbox {Lsf}_i\) :

-

Load sharing of tooth pair i

- \(T_{\mathrm{p}}\) :

-

Input torque on the pinion

- \(T_{\mathrm{g}}\) :

-

Output torque on the gear

- \(c_{\mathrm{m}}\) :

-

Linear damping element

- e :

-

No-load transmission error

- \(h_{\mathrm{m}},\,h_{i}\) :

-

Contact coefficient

- \(r_\mathrm{bp},\,r_\mathrm{bg}\) :

-

Radius of the base circle of the pinion and the gear

- \(f_{\mathrm{s}}\) :

-

Rotational frequency of pinion

- \(f_{\mathrm{m}}\) :

-

Mesh frequency

References

Liu, G., Parker, R.G.: Dynamic modeling and analysis of tooth profile modification for multimesh gear vibration. J. Mech. Des. 130(12), 121402 (2008)

Cao, Z., Shao, Y., Rao, M., Yu, W.: Effects of the gear eccentricities on the dynamic performance of a planetary gear set. Nonlinear Dyn. 91(1), 1–15 (2018)

Zhang, T., Chen, Z., Zhai, W., Wang, K.: Establishment and validation of a locomotive-track coupled spatial dynamics model considering dynamic effect of gear transmissions. Mech. Syst. Signal Process. 119, 328–345 (2019)

Özgüven, H.N., Houser, D.R.: Dynamic analysis of high speed gears by using loaded static transmission error. J. Sound Vib. 125(1), 71–83 (1988)

Kahraman, A., Singh, R.: Non-linear dynamics of a spur gear pair. J. Sound Vib. 142(1), 49–75 (1990)

Kahraman, A., Singh, R.: Non-linear dynamics of a geared rotor-bearing system with multiple clearance. J. Sound Vib. 144(3), 469–509 (1991)

Kahraman, A., Singh, R.: Interactions between time-varying mesh stiffness and clearance non-linearities in a geared system. J. Sound Vib. 146(1), 135–156 (1991)

Lin, H.H., Oswald, F.B., Townsend, D.P.: Dynamic loading of spur gears with linear or parabolic tooth profile modifications. Mech. Mach. Theory 29(8), 1115–1129 (1994)

He, S., Gunda, R., Singh, R.: Effect of sliding friction on the dynamics of spur gear pair with realistic time-varying stiffness. J. Sound Vib. 301(3–5), 927–949 (2007)

Velex, P., Maatar, M.: A mathematical model for analyzing the influence of shape deviations and mounting errors on gear dynamic behaviour. J. Sound Vib. 191(5), 629–660 (1996)

Yang, D.C.H., Lin, J.Y.: Hertzian damping, tooth friction and bending elasticity in gear impact dynamics. J. Mech. Transm. Autom. Des. 109(2), 189–196 (1987)

Huang, K.J., Wu, M.R., Tseng, J.T.: Dynamic analyses of gear pairs incorporating the effect of time-varying lubrication damping. J. Vib. Control 17(3), 355–363 (2011)

Guilbault, R., Lalonde, S., Thomas, M.: Nonlinear damping calculation in cylindrical gear dynamic modeling. J. Sound Vib. 331(9), 2110–2128 (2012)

Amabili, M., Rivola, A.: Dynamic analysis of spur gear pairs: steady-state response and stability of the SDOF model with time-varying meshing damping. Mech. Syst. Signal Process. 11(3), 375–390 (1997)

Chen, S., Tang, J., Wu, L.: Dynamics analysis of a crowned gear transmission system with impact damping: based on experimental transmission error. Mech. Mach. Theory 74, 354–369 (2014)

Mark, W.D.: Analysis of the vibratory excitation of gear systems. II. Tooth error representations, approximations, and application. J. Acoust. Soc. Am. 66(6), 1758–1787 (1979)

Jia, S., Howard, I.: Comparison of localised spalling and crack damage from dynamic modelling of spur gear vibrations. Mech. Syst. Signal Process. 20(2), 332–349 (2006)

Chen, Z., Shao, Y.: Dynamic features of planetary gear train with tooth errors. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 229(10), 1769–1781 (2015)

Bahk, C.J., Parker, R.G.: Analytical investigation of tooth profile modification effects on planetary gear dynamics. Mech. Mach. Theory 70, 298–319 (2013)

Yu, W., Mechefske, C.K.: Analytical modeling of spur gear corner contact effects. Mech. Mach. Theory 96, 146–164 (2016)

Liu, S., Song, C., Zhu, C., Liang, C., Yang, X.: Investigation on the influence of work holding equipment errors on contact characteristics of face-hobbed hypoid gear. Mech. Mach. Theory 138, 95–111 (2019)

Cornell, R.W.: Compliance and stress sensitivity of spur gear teeth. J. Mech. Des. 103(2), 447–459 (1981)

Chen, Z., Shao, Y.: Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth. Eng. Fail. Anal. 18(8), 2149–2164 (2011)

Chen, Z., Zhai, W., Wang, K.: Vibration feature evolution of locomotive with tooth root crack propagation of gear transmission system. Mech. Syst. Signal Process. 115, 29–44 (2019)

Arafa, M.H., Megahed, M.M.: Evaluation of spur gear mesh compliance using the finite element method. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 213(6), 569–579 (1999)

Wang, J., Howard, I.: The torsional stiffness of involute spur gears. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 218(1), 131–142 (2004)

Wang, J., Howard, I.: Finite element analysis of high contact ratio spur gears in mesh. J. Tribol. 127(3), 469–483 (2005)

Vedmar, L., Henriksson, B.: A general approach for determining dynamic forces in spur gears. J. Mech. Des. 120(4), 593–598 (1998)

Del Rincon, A.F., Viadero, F., Iglesias, M., García, P., De-Juan, A., Sancibrian, R.: A model for the study of meshing stiffness in spur gear transmissions. Mech. Mach. Theory 61, 30–58 (2013)

Parker, R.G., Agashe, V., Vijayakar, S.M.: Dynamic response of a planetary gear system using a finite element/contact mechanics model. J. Mech. Des. 122(3), 304–310 (2000)

Weber, C.: The Deformation of Loaded Gears and the Effect on their Load Carrying Capacity. Department of Scientific and Industrial Research, London (1951)

Sainsot, P., Velex, P., Duverger, O.: Contribution of gear body to tooth deflections—a new bidimensional analytical formula. J. Mech. Des. 126(4), 748–752 (2004)

Chen, Z., Zhang, J., Zhai, W., Wang, Y., Liu, J.: Improved analytical methods for calculation of gear tooth fillet-foundation stiffness with tooth root crack. Eng. Fail. Anal. 82, 72–81 (2017)

Chen, Z., Shao, Y.: Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack. Mech. Mach. Theory 62, 63–74 (2013)

Tavakoli, M.S., Houser, D.R.: Optimum profile modifications for the minimization of static transmission errors of spur gears. J. Mech. Transm. Autom. Des. 108(1), 86–94 (1986)

Kahraman, A., Blankenship, G.W.: Experiments on nonlinear dynamic behavior of an oscillator with clearance and periodically time-varying parameters. J. Appl. Mech. 64(1), 217–226 (1997)

Kahraman, A., Blankenship, G.W.: Effect of involute tip relief on dynamic response of spur gear pairs. J. Mech. Des. 121(2), 313–315 (1999)

Funding

The authors are grateful for the financial support provided by the National Natural Science Foundation of China (Grant Nos. 51775453 and 51605412), the Sichuan Science and Technology Program (Grant No. 2018JY0159).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, Z., Chen, Z. & Jiang, H. Nonlinear dynamics of a spur gear pair with force-dependent mesh stiffness. Nonlinear Dyn 99, 1227–1241 (2020). https://doi.org/10.1007/s11071-019-05348-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-019-05348-0