Abstract

Rotating shaft–disk–blade (RSDB) system is one of the most important parts of turbomachinery, such as aero-engine, gas turbine and power plant. The coupling vibration of RSDB system with blade crack is vital for the blade health monitoring and crack detection of rotating blade. This study aims at addressing the dynamic modeling and steady-state coupling vibration mechanism of RSDB system with blade crack. First and foremost, on the basis of the stress state at crack section, an improved analytical breathing crack model (modified stress-based breathing crack model, MSBCM) for rotating blade is proposed. The validity of the proposed breathing crack model is verified by comparing the results obtained by MSBCM, finite element contact crack model and conventional analytical crack models. The comparative results suggest that MSBCM is of high fidelity and behaves best among the analytical crack models. Subsequently, a comprehensive dynamic model of the coupling vibration for RSDB system with blade crack is formulated on the basis of continuum beam theory and Lagrange equation. The shaft bending, shaft torsion, blade bending and blade radial deformation are comprehensively considered in this model. The validity of the proposed dynamic model is verified through comparison with finite element simulation and experimentation results. By introducing the proposed MSBCM, the dynamic coupling vibration model of the RSDB system with blade crack is formulated. At last, the steady-state coupling vibration mechanism of two typical structures for RSDB system is comprehensively investigated. It is suggested that the shaft torsional vibration is much more sensitive to blade crack than the shaft bending vibration be, which indicates that the vibration features of shaft torsional vibration may offer indicators for the presence of blade crack.

Similar content being viewed by others

Abbreviations

- \(\gamma \) :

-

Relative crack location

- \(\lambda \) :

-

Relative crack depth

- \(\nu _\mathrm{b}\) :

-

Poisson ratio of blade

- \(\omega \) :

-

Shaft rotating speed

- \(\psi _\mathrm{s}\) :

-

Shaft torsional vibration displacement

- \(\varphi _{K_j}\) :

-

Phase of excitation force

- \(A_\mathrm{b}\) :

-

Blade cross-section area

- \(a_\mathrm{c}\) :

-

Crack depth

- \(A_\mathrm{s}\) :

-

Shaft cross-section area

- \(E_\mathrm{b}\) :

-

Elastic modulus of blade

- \(E_\mathrm{d}\) :

-

Elastic modulus of disk

- \(E_\mathrm{s}\) :

-

Elastic modulus of shaft

- \(f(y_0)\) :

-

Breathing function of the SBCM

- \(F_0\) :

-

Load amplitude

- \(f_\mathrm{c}(x)\) :

-

Centrifugal force of rotating blade

- \(f_{v_{i}}(x,t)\) :

-

Excitation force loaded on the \(i\mathrm{th}\) blade

- \(g(y_0)\) :

-

Breathing function of the MSBCM

- \(h_\mathrm{b}\) :

-

Blade height

- \(h_\mathrm{d}\) :

-

Disk thickness

- \(I_\mathrm{b}\) :

-

Polar potential moment of inertial of blade cross section

- \(I_\mathrm{b}\) :

-

Polar potential moment of inertial of shaft cross section

- \(K_\mathrm{I}\) :

-

Stress intensity factor at crack tip

- \(L_\mathrm{b}\) :

-

Blade length

- \(l_\mathrm{c}\) :

-

Crack location

- \(L_\mathrm{s}\) :

-

Shaft length

- \(N_\mathrm{b}\) :

-

Number of blades installed on rotating disk

- \(P_0\) :

-

DC component of excitation force

- \(P_{K_j}\) :

-

Aerodynamic force amplitude

- \(Q({\lambda })\) :

-

Geometrical correction factor

- \(R_\mathrm{d}\) :

-

Disk radius

- u, v, w :

-

Blade vibration displacements in span-wise, lateral and chordwise directions

- \(x_\mathrm{d}\), \(y_\mathrm{d}\), \(z_\mathrm{d}\) :

-

Shaft displacements at disk

- \(x_\mathrm{s}\), \(y_\mathrm{s}\) :

-

Shaft bending vibration displacements in lateral directions

- \(y_\mathrm{c}\) :

-

Height of crack tip

- \({\sigma _{{\mathrm{bu}}}}\) :

-

Unit bending stress at the crack section

- \({\sigma _{{\mathrm{c}}}}\) :

-

Centrifugal stress at the crack section

- \({\theta _{{\mathrm{s}}x}}\), \({\theta _{{\mathrm{s}}y}}\) :

-

Shaft rotational displacement along with axes OX and OY

- \({{\varvec{{D}}}_{\text {b}}}\) :

-

Damping coefficients matrix of blade

- \({{\varvec{{D}}}_{\text {RB}}}\) :

-

Damping coefficients matrix of RSDB system

- \({{\varvec{{F}}}_{\text {b}}}\) :

-

External force vector of blade

- \({{\varvec{{F}}}_{\text {RB}}}\) :

-

External force vector of RSDB system

- \({{\varvec{{G}}}_{\text {b}}}\) :

-

Gyroscopic matrix of blade

- \({{\varvec{{G}}}_{\text {RB}}}\) :

-

Gyroscopic matrix of RSDB system

- \({{\varvec{{K}}}^\mathrm{\Omega }_{\text {RB}}}\) :

-

Spin softening stiffness matrix of RSDB system

- \({{\varvec{{K}}}^\mathrm{e}_{\text {RB}}}\) :

-

Structure stiffness matrix of RSDB system

- \({{\varvec{{K}}}_{\text {acc}}}\) :

-

Stiffness matrix caused by acceleration of blade

- \({{\varvec{{K}}}_{\text {b}}}\) :

-

Stiffness matrix of blade

- \({{\varvec{{K}}}_{\text {cr}}}\) :

-

Stiffness alteration caused by fully open crack

- \({{\varvec{{K}}}_{\text {e}}}\) :

-

Structural stiffness matrix of blade

- \({{\varvec{{K}}}_{\text {so}}}\) :

-

Spin softening matrix of blade

- \({{\varvec{{K}}}_{\text {st}}}\) :

-

Centrifugal stiffening matrix of blade

- \({{\varvec{{M}}}_{\text {b}}}\) :

-

Mass matrix of blade

- \({{\varvec{{M}}}_{\text {RB}}}\) :

-

Mass matrix of RSDB system

References

Abdelrhman, A.M., Leong, M.S., Saeed, S.A.M., Al Obiadi, S.M., et al.: A review of vibration monitoring as a diagnostic tool for turbine blade faults. In: Othman M. (ed) Applied Mechanics and Materials, vol. 229. Trans Tech Publ, pp. 1459–1463 (2012)

Carter, T.J.: Common failures in gas turbine blades. Eng. Fail. Anal. 12, 237–247 (2005)

Yang, L., Chen, X., Wang, S.: Mechanism of fast time-varying vibration for rotor-stator contact system: with application to fault diagnosis. J. Vib. Acoust. 140, 014501 (2018)

Gates, D.: Rolls-Royce Spending Millions of Dollars to Repair 787 Engines. The Seattle Times (2018)

Abdelrhman, A.M., Hee, L.M., Leong, M., Al-Obaidi, S.: Condition monitoring of blade in turbomachinery: a review. Adv. Mech. Eng. 6, 210717 (2014)

Gubran, A.: Vibration Diagnosis of Blades of Rotating Machines, Ph.D. thesis, The University of Manchester (United Kingdom) (2015)

Rao, J.: Turbomachine Blade Vibration. New Age International (1991)

Sun, J.: Vibration Characteristics and Structural Damping of Rotating Compressor Blades, Ph.D. thesis. KTH Royal Institute of Technology, Stockholm (2012)

Ma, H., Yin, F., Guo, Y., Tai, X., Wen, B.: A review on dynamic characteristics of blade-casing rubbing. Nonlinear Dyn. 84, 437–472 (2016)

Rafiee, M., Nitzsche, F., Labrosse, M.: Dynamics, vibration and control of rotating composite beams and blades: a critical review. Thin Walled Struct. 119, 795–819 (2017)

Rao, J.: History of Rotating Machinery Dynamics. Springer, Chennai (2011)

Yao, J., Wang, J., Li, Q.: Robustness analysis of mistuned bladed disk using the upper bound of structured singular value. J. Eng. Gas Turbines Power 131, 032501 (2009)

Kwon, S., Yoo, H.H.: Mode and transient response localization occurred in rotating multi-packet blade systems due to random mistuning. Int. J. Precis. Eng. Manuf. 16, 2063–2071 (2015)

Yuan, J., Scarpa, F., Allegri, G., Titurus, B., Patsias, S., Rajasekaran, R.: Efficient computational techniques for mistuning analysis of bladed discs: a review. Mech. Syst. Signal Process. 87, 71–90 (2017)

Kan, X., Xu, Z.: Vibration localization for a rotating mistuning bladed disk with the Coriolis effect by a state-space decoupling method. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 233, 1011–1020 (2019)

Xie, J.: Research on the Dynamics Modeling and Identification Method of Blade–Disc–Rotor System with Crack Faults, Ph.D. thesis, Xi’an Jiaotong University, Xi’an, China (2018)

She, H., Li, C., Tang, Q., Wen, B.: The investigation of the coupled vibration in a flexible-disk blades system considering the influence of shaft bending vibration. Mech. Syst. Signal Process. 111, 545–569 (2018)

Wang, L.: Nonlinear Dynamical Behaviors of the Coupling Blade–Rotor–Bearing System (in Chinese), Ph.D. thesis. Harbin Institute of Technology, Harbin (2009)

Zhenyong, L.: Dynamical Modeling and Nonlinear Vibration Study of Aero-Engine Rotor System, Ph.D. thesis. Harbin Institute of Technology, Harbin (2015)

Ma, H., Lu, Y., Wu, Z., Tai, X., Li, H., Wen, B.: A new dynamic model of rotor–blade systems. J. Sound Vib. 357, 168–194 (2015)

Yu, P., Zhang, D., Ma, Y., Hong, J.: Dynamic modeling and vibration characteristics analysis of the aero-engine dual-rotor system with fan blade out. Mech. Syst. Signal Process. 106, 158–175 (2018)

Huang, B.-W., Kuang, J.-H.: Variation in the stability of a rotating blade disk with a local crack defect. J. Sound Vib. 294, 486–502 (2006)

Al-Bedoor, B.: Natural frequncies of coupled blade-bending and shaft-torsional vibrations. Shock Vib. 14, 65–80 (2007)

Chiu, Y.J., Chen, D.Z., Yang, C.H.: Influence on coupling vibration of rotor system with grouped blades due to mistuned lacing wire. In: Di Zheng (ed) Applied Mechanics and Materials, vol. 101. Trans Tech Publ, pp. 1119–1125 (2012)

Ma, H., Yin, F., Wu, Z., Tai, X., Wen, B.: Nonlinear vibration response analysis of a rotor–blade system with blade-tip rubbing. Nonlinear Dyn. 84, 1225–1258 (2016)

Li, C., She, H., Tang, Q., Wen, B.: The coupling vibration characteristics of a flexible shaft–disk–blades system with mistuned features. Appl. Math. Model. 67, 557–572 (2019)

Yang, C.-H., Huang, S.-C.: Coupling vibrations in rotating shaft–disk–blades system. J. Vib. Acoust. 129, 48–57 (2007)

She, H., Li, C., Tang, Q., Wen, B.: Effects of blade’s interconnection on the modal characteristics of a shaft–disk–blade system. Mech. Syst. Signal Process. 146, 106955 (2020)

Kuang, J., Huang, B.: Mode localization of a cracked blade-disks. In: ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition. American Society of Mechanical Engineers, pp. V005T14A013 (1998)

Xu, H., Chen, Z., Xiong, Y., Yang, Y., Tao, L.: Nonlinear dynamic behaviors of rotated blades with small breathing cracks based on vibration power flow analysis. Shock Vib. 2016, 4197203 (2016)

Xu, H., Chen, Z., Yang, Y., Tao, L., Chen, X.: Effects of crack on vibration characteristics of mistuned rotated blades. Shock Vib. 2017. 1785759 (2017)

Saito, A.: Nonlinear Vibration Analysis of Cracked Structures: Application to Turbo-machinery Rotors with Cracked Blades, Ph.D. thesis, Citeseer (2009)

Chiu, Y.-J., Huang, S.-C.: The influence on coupling vibration of a rotor system due to a mistuned blade length. Int. J. Mech. Sci. 49, 522–532 (2007)

Yu, G.-F., Chiu, Y.-J., Yang, C.-H., Sheng, J., Li, X.-Y.: Exploration of coupled-vibration phenomena in multi-disk rotor with blades with multi-cracks. Adv. Mech. Eng. 11, 1687814019837398 (2019)

Liu, C., Jiang, D.: Crack modeling of rotating blades with cracked hexahedral finite element method. Mech. Syst. Signal Process. 46, 406–423 (2014)

Andreaus, U., Casini, P., Vestroni, F.: Non-linear dynamics of a cracked cantilever beam under harmonic excitation. Int. J. Non Linear Mech. 42, 566–575 (2007)

Xie, J., Zi, Y., Zhang, M., Luo, Q.: A novel vibration modeling method for a rotating blade with breathing cracks. Sci. China Technol. Sci. 62, 333–348 (2019)

Bovsunovsky, A., Surace, C.: Non-linearities in the vibrations of elastic structures with a closing crack: a state of the art review. Mech. Syst. Signal Process. 62, 129–148 (2015)

Dimarogonas, A.D., Paipetis, S.A., Chondros, T.G.: Analytical Methods in Rotor Dynamics. Springer, Berlin (2013)

Tata, H., Paris, P., Irwin, G.: The Stress Analysis of Crack Handbook, 3rd edn. Del Research Corporation, Turkapally (2000)

Ma, H., Zeng, J., Lang, Z., Zhang, L., Guo, Y., Wen, B.: Analysis of the dynamic characteristics of a slant-cracked cantilever beam. Mech. Syst. Signal Process. 75, 261–279 (2016)

Li, C.-F., She, H.-X., Liu, W., Wen, B.-C.: The influence of shaft’s bending on the coupling vibration of a flexible blade-rotor system. Math. Probl. Eng. 2017, 7313956 (2017)

Rao, S.S.: Mechanical Vibrations. Sixth Edition in SI Units, Pearson (2018)

Jousselin, O.: Development of Blade Tip Timing Techniques in Turbo Machinery, Ph.D. thesis, Thesis, Faculty of Engineering and Physical Sciences, School of Mechanical Aerospace and Civil Engineering, Manchester University (2013)

Xu, H.: Research on Key Tecknology of Crack Detection in Rotating Blades by Non-contact On-line Blade Tip-Timing Method, Ph.D. thesis. National University of Defense Tecchnology, Changsha (2018)

Wu, S., Zhao, Z., Yang, Z., Tian, S., Yang, L., Chen, X.: Physical constraints fused equiangular tight frame method for blade tip timing sensor arrangement. Measurement 145, 841–851 (2019)

She, H., Li, C., Tang, Q., Wen, B.: Influence mechanism of disk position and flexibility on natural frequencies and critical speeds of a shaft–disk–blade unit. J. Sound Vib. 469, 115156 (2020)

Zeng, J., Ma, H., Zhang, W., Wen, B.: Dynamic characteristic analysis of cracked cantilever beams under different crack types. Eng. Fail. Anal. 74, 80–94 (2017)

Andreaus, U., Baragatti, P.: Cracked beam identification by numerically analysing the nonlinear behaviour of the harmonically forced response. J. Sound Vib. 330, 721–742 (2011)

Zeng, J., Chen, K., Ma, H., Duan, T., Wen, B.: Vibration response analysis of a cracked rotating compressor blade during run-up process. Mech. Syst. Signal Process. 118, 568–583 (2019)

Zili, X., Song, A. (2018) Blade Structure Strength and Vibration (in Chinese). Xi’an Jiaotong University Press, Xi’an

Mokrani, B.: Piezoelectric Shunt Damping of Rotationally Periodic Structures, Ph.D. thesis. Université Libre de Bruxelles, Bruxelles (2015)

Acknowledgements

This work is sponsored by the National Major Project of China (No. 2017-V-0009) and the Natural Science Foundation of China (No. 51705397). The first author acknowledges the host and support from the Structural Dynamics and Acoustic Systems Laboratory at the University of Massachusetts Lowell. The authors acknowledge the Laboratory of Science and Technology on Integrated Logistics Support at National University of Defense Technology for providing the blade vibration measurement test rig.

Author information

Authors and Affiliations

Contributions

Lai-Hao Yang contributed to theory modeling, numerical simulation, experimental verification, writing—original draft. Zhu Mao contributed to conceptualization, supervision, writing—review and editing. Shu-Ming Wu contributed to conceptualization, numerical simulation, experimental verification. Xue-Feng Chen contributed to conceptualization, supervision, funding acquisition, project administration. Ru-Qiang Yan contributed to supervision, writing—review and editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Matrices and vectors related to RSDB system

Matrices and vectors related to RSDB system

-

(1)

\({{\mathbf {M}}_{\text {s}}}\) is the lumped mass matrix related to the shaft translation and bending and can be shown as follows

$$\begin{aligned} {\mathbf{M}}_{\mathrm{s}}^{}{\mathrm{= }}\left[ {\begin{array}{*{20}{c}} {{\mathbf{M}}_{{\mathrm{s1}}}^{{\mathrm{shaft}}}}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{{\mathbf{M}}_{{\mathrm{s2}}}^{{\mathrm{shaft}}}} \end{array}} \right] + \left[ {\begin{array}{*{20}{c}} {{\mathbf{M}}_{{\mathrm{s1}}}^{{\mathrm{disc}}}}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{{\mathbf{M}}_{{\mathrm{s2}}}^{{\mathrm{disc}}}} \end{array}} \right] + \left[ {\begin{array}{*{20}{c}} {{\mathbf{M}}_{{\mathrm{s1}}}^{{\mathrm{blade}}}}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{{\mathbf{M}}_{{\mathrm{s2}}}^{{\mathrm{blade}}}} \end{array}} \right] \end{aligned}$$(A.1)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{M}}_{{\mathrm{s1}}}^{{\mathrm{shaft}}}{\mathrm{= }}\displaystyle \int _0^{{L_{\mathrm{s}}}} {{\rho _{\mathrm{s}}}{A_{\mathrm{s}}}\left( {{{\mathbf{X}}^{\mathrm{T}}}{\mathbf{X}}} \right) } {\mathrm{d}}z + \displaystyle \int _0^{{L_{\mathrm{s}}}} {{J_{{\mathrm{ds}}}}\left( {{{{\mathbf{X'}}}^{\mathrm{T}}}{\mathbf{X'}}} \right) } {\mathrm{d}}z\\ {\mathbf{M}}_{{\mathrm{s2}}}^{{\mathrm{shaft}}}{\mathrm{= }}\displaystyle \int _0^{{L_{\mathrm{s}}}} {{\rho _{\mathrm{s}}}{A_{\mathrm{s}}}\left( {{{\mathbf{Y}}^{\mathrm{T}}}{\mathbf{Y}}} \right) } {\mathrm{d}}z + \displaystyle \int _0^{{L_{\mathrm{s}}}} {{J_{{\mathrm{ds}}}}\left( {{{{\mathbf{Y'}}}^{\mathrm{T}}}{\mathbf{Y'}}} \right) } {\mathrm{d}}z \end{array} \right. \end{aligned}$$(A.2a)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{M}}_{{\mathrm{s1}}}^{{\mathrm{disc}}} = {m_{\mathrm{d}}}{{\mathbf{X}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X}}\left( {{z_{\mathrm{d}}}} \right) {\mathrm{+ }}{J_{{\mathrm{dd}}}}{{{\mathbf{X'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) \\ {\mathbf{M}}_{{\mathrm{s2}}}^{{\mathrm{disc}}} = {m_{\mathrm{d}}}{{\mathbf{Y}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y}}\left( {{z_{\mathrm{d}}}} \right) {\mathrm{+ }}{J_{{\mathrm{dd}}}}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y'}}\left( {{z_{\mathrm{d}}}} \right) \end{array} \right. \end{aligned}$$(A.2b)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{M}}_{{\mathrm{s1}}}^{{\mathrm{blade}}} = {N_{\mathrm{b}}}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\mathbf{X}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X}}\left( {{z_{\mathrm{d}}}} \right) + \dfrac{1}{2}{{\left( {{R_{\mathrm{d}}} + x} \right) }^2}{{{\mathbf{X'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x\;} \\ {\mathbf{M}}_{{\mathrm{s2}}}^{{\mathrm{blade}}} = {N_{\mathrm{b}}}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\mathbf{Y}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y}}\left( {{z_{\mathrm{d}}}} \right) + \dfrac{1}{2}{{\left( {{R_{\mathrm{d}}} + x} \right) }^2}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.2c) -

(2)

\({{\mathbf {M}}_{\uptheta }}\) is the lumped mass matrix related to shaft torsional vibration and can be shown as follows

$$\begin{aligned}&{{\varvec{M}}_{\varvec{\theta }}} = {\varvec{M}}_{\varvec{\theta }}^{{\mathrm{shaft}}} + {\mathbf{M}}_{\varvec{\theta }}^{{\mathrm{disc}}} + {\varvec{M}}_{\varvec{\theta }}^{{\mathrm{blade}}} \end{aligned}$$(A.3)$$\begin{aligned}&\left\{ \begin{array}{l} {\varvec{M}}_{\varvec{\theta }}^{{\mathrm{shaft}}}{\mathrm{= }}\displaystyle \int _0^{{L_{\mathrm{s}}}} {{J_{{\mathrm{ps}}}}\left( {{{\varvec{\Psi }}^{\mathrm{T}}}{\varvec{\Psi }}} \right) } {\mathrm{d}}z\\ {\varvec{M}}_{\varvec{\theta }}^{{\mathrm{disc}}}={J_{{\mathrm{pd}}}}{{\varvec{\Psi }}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\varvec{\Psi }}\left( {{z_{\mathrm{d}}}} \right) + {m_{\mathrm{d}}}{e^2}{{\varvec{\Psi }}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\varvec{\Psi }}\left( {{z_{\mathrm{d}}}} \right) \\ {\varvec{M}}_{\varvec{\theta }}^{{\mathrm{blade}}}={N_{\mathrm{b}}}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\left( {R_{\mathrm{d}} + x} \right) }^2}{{\mathbf{\Psi }}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{\Psi }}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.4) -

(3)

\({{\varvec{M}}_{{{\mathrm{B}}_i}}} \) is the mass matrix related to blade bending and can be shown as follows

$$\begin{aligned}&{{\varvec{M}}_{{{\mathrm{B}}_i}}} = \left[ {\begin{array}{*{20}{c}} {{\varvec{M}}_{{{\mathrm{B}}_i}}^u}&{}{}\\ {}&{}{{\varvec{M}}_{{{\mathrm{B}}_i}}^v} \end{array}} \right] \end{aligned}$$(A.5)$$\begin{aligned}&\left\{ {\begin{array}{*{20}{l}} {{\varvec{M}}_{{{\mathrm{B}}_i}}^u = {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\mathbf{U}}^{\mathrm{T}}}{\mathbf{U}}} \right] {\mathrm{d}}x} }\\ {{\varvec{M}}_{{{\mathrm{B}}_i}}^v = {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\mathbf{V}}^{\mathrm{T}}}{\mathbf{V}}} \right] {\mathrm{d}}x} } \end{array}} \right. \end{aligned}$$(A.6) -

(4)

\({{\mathbf{G}}_{{{\mathrm{s}}}}} \) is the lumped gyroscopic matrix related the shaft rotation and can be shown as follows:

$$\begin{aligned} {\mathbf{G}}_{\mathrm{s}}^{}{\mathrm{= }}\left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{{\mathbf{G}}_{{\mathrm{s1}}}^{{\mathrm{shaft}}}}\\ {{\mathbf{G}}_{{\mathrm{s2}}}^{{\mathrm{shaft}}}}&{}{\mathbf{0}} \end{array}} \right] + \left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{{\mathbf{G}}_{{\mathrm{s1}}}^{{\mathrm{disc}}}}\\ {{\mathbf{G}}_{{\mathrm{s2}}}^{{\mathrm{disc}}}}&{}{\mathbf{0}} \end{array}} \right] + \left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{{\mathbf{G}}_{{\mathrm{s1}}}^{{\mathrm{blade}}}}\\ {{\mathbf{G}}_{{\mathrm{s2}}}^{{\mathrm{blade}}}}&{}{\mathbf{0}} \end{array}} \right] \end{aligned}$$(A.7)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{G}}_{{\mathrm{s1}}}^{{\mathrm{shaft}}}=\Omega \displaystyle \int _0^{{L_{\mathrm{s}}}} {{J_{{\mathrm{ps}}}}{{{\mathbf{Y'}}}^{\mathrm{T}}}{\mathbf{X'}}} {\mathrm{d}}z\\ {\mathbf{G}}_{{\mathrm{s2}}}^{{\mathrm{shaft}}} = - \Omega \displaystyle \int _0^{{L_{\mathrm{s}}}} {{J_{{\mathrm{ps}}}}{{{\mathbf{X'}}}^{\mathrm{T}}}{\mathbf{Y'}}} {\mathrm{d}}z \end{array} \right. \end{aligned}$$(A.8a)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{G}}_{{\mathrm{s1}}}^{{\mathrm{disc}}} = \Omega {J_{{\mathrm{pd}}}}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) \\ {\mathbf{G}}_{{\mathrm{s2}}}^{{\mathrm{disc}}} = - \Omega {J_{{\mathrm{pd}}}}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) \end{array} \right. \end{aligned}$$(A.8b)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{G}}_{{\mathrm{s1}}}^{{\mathrm{blade}}} = \Omega {N_{\mathrm{b}}}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\left( {R_{\mathrm{d}} + x} \right) }^2}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \\ {\mathbf{G}}_{{\mathrm{s2}}}^{{\mathrm{blade}}} = - \Omega {N_{\mathrm{b}}}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\left( {R_{\mathrm{d}} + x} \right) }^2}{{{\mathbf{X'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.8c) -

(5)

\({{\mathbf{G}}_{{{\mathrm{B}}_{i}}}} \) is the lumped gyroscopic matrix related the shaft rotation and can be shown as follows

$$\begin{aligned}&{\mathbf{G}}_{{{\mathrm{B}}_i}}^{}= \left[ {\begin{array}{*{20}{c}} {}&{}{{\mathbf{G}}_{{{\mathrm{B}}_i}}^{vu}}\\ {{\mathbf{G}}_{{{\mathrm{B}}_i}}^{uv}}&{}{} \end{array}} \right] \end{aligned}$$(A.9)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{G}}_{\mathrm{s}}^{vu} = - 2\Omega {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {\cos \left( \beta \right) {{\mathbf{U}}^{\mathrm{T}}}{\mathbf{V}}} \right] {\mathrm{d}}x} \\ {\mathbf{G}}_{\mathrm{s}}^{uv} = 2\Omega {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {\cos \left( \beta \right) {{\mathbf{V}}^{\mathrm{T}}}{\mathbf{U}}} \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.10) -

(6)

\({{\mathbf{K}}_{{{\mathrm{S}}}}} \) is the structure stiffness matrix related to shaft bending deformation and can be shown as follows

$$\begin{aligned}&{{\mathbf{K}}_{\mathrm{S}}} = \left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{S1}}}^{\mathrm{e}}}&{}{}\\ {}&{}{{\mathbf{K}}_{{\mathrm{S2}}}^{\mathrm{e}}} \end{array}} \right] \end{aligned}$$(A.11)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{K}}_{{\mathrm{S1}}}^{\mathrm{e}} =\displaystyle \int _0^{{L_{\mathrm{s}}}} {{E_{\mathrm{s}}}{I_{\mathrm{s}}}\left( {{{{\mathbf{X''}}}^{\mathrm{T}}}{\mathbf{X''}}} \right) } {\mathrm{d}}z\\ {\mathbf{K}}_{{\mathrm{S2}}}^{\mathrm{e}} = \displaystyle \int _0^{{L_{\mathrm{s}}}} {{E_{\mathrm{s}}}{I_{\mathrm{s}}}\left( {{{{\mathbf{Y''}}}^{\mathrm{T}}}{\mathbf{Y''}}} \right) } {\mathrm{d}}z \end{array} \right. \end{aligned}$$(A.12) -

(7)

\({\mathbf{K}}_{\mathrm{\uptheta }}^{\mathrm{e}}\) is the structure stiffness matrix related to shaft torsional deformation and can be shown as follows

$$\begin{aligned} {{\mathbf{K}}_{\mathrm{\theta }}^{\mathrm{e}} = \int _0^{{L_{\mathrm{s}}}} {{G_{\mathrm{s}}}{J_{\mathrm{s}}}\left( {{{{\varvec{\Psi '}}}^{\mathrm{T}}}{\varvec{\Psi '}}} \right) } {\mathrm{d}}z} \end{aligned}$$(A.13)(8) \({{\mathbf{K}}_{{{\mathrm{S}}}}} \) is the structure stiffness matrix related to blade bending deformation and can be shown as follows

$$\begin{aligned}&{{\mathbf {K}}_{{{\text {B}}_i}}} = \left[ {\begin{array}{*{20}{c}} {{\mathbf {K}}_{{\text {u}}i}^{\text {e}}}&{}{} \\ {}&{}{{\mathbf {K}}_{{\text {v}}i}^{\text {e}}} \end{array}} \right] \end{aligned}$$(A.14)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{K}}_{{\mathrm{u}}i}^{\mathrm{e}} = {E_{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{{\mathbf{U'}}}^{\mathrm{T}}}{\mathbf{U'}}} \right] {\mathrm{d}}x} \\ {\mathbf{K}}_{{\mathrm{v}}i}^{\mathrm{e}} = {E_{\mathrm{b}}}{I_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{{\mathbf{V''}}}^{\mathrm{T}}}{\mathbf{V''}}} \right] {\mathrm{d}}x} + \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {{f_{\mathrm{c}}}\left( x \right) \left[ {{{{\mathbf{V'}}}^{\mathrm{T}}}{\mathbf{V'}}} \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.15) -

(9)

\({\mathbf{K}}_{\mathrm{s}}^\Omega \) is the spin softening stiffness matrix caused by disk and blade spinning, which affects the shaft bending vibration and can be shown as follows

$$\begin{aligned} {\mathbf{K}}_{\mathrm{s}}^\Omega = {\mathbf{K}}_{\mathrm{s}}^{\Omega {\mathrm{disc}}} + {\mathbf{K}}_{\mathrm{s}}^{\Omega {\mathrm{blade}}} = \left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{s1}}}^{\Omega {\mathrm{disc}}}}&{}{}\\ {}&{}{{\mathbf{K}}_{{\mathrm{s2}}}^{\Omega {\mathrm{disc}}}} \end{array}} \right] + \left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{s1}}}^{\Omega {\mathrm{blade}}}}&{}{}\\ {}&{}{{\mathbf{K}}_{{\mathrm{s2}}}^{\Omega {\mathrm{blade}}}} \end{array}} \right] \nonumber \\ \end{aligned}$$(A.16)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{K}}_{{\mathrm{s}}1}^{\Omega {\mathrm{disc}}} = {\Omega ^2}{J_{{\mathrm{dd}}}}{{{\mathbf{X'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) \\ {\mathbf{K}}_{{\mathrm{s2}}}^{\Omega {\mathrm{disc}}} = {\Omega ^2}{J_{{\mathrm{dd}}}}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y'}}\left( {{z_{\mathrm{d}}}} \right) \end{array} \right. \end{aligned}$$(A.17a)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{K}}_{{\mathrm{s1}}}^{\Omega {\mathrm{blade}}} = \dfrac{1}{2}{N_{\mathrm{b}}}{\Omega ^2}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\left( {R_{\mathrm{d}} + x} \right) }^2}{{{\mathbf{X'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{X'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \\ {\mathbf{K}}_{{\mathrm{s2}}}^{\Omega {\mathrm{blade}}} = \dfrac{1}{2}{N_{\mathrm{b}}}{\Omega ^2}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\left( {R_{\mathrm{d}} + x} \right) }^2}{{{\mathbf{Y'}}}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.17b) -

(10)

\({\mathbf{K}}_{\mathrm{s}}^\Omega \) is the spin softening stiffness matrix caused by disk and blade spinning, which affects the shaft torsional vibration and can be shown as follows

$$\begin{aligned}&{\mathbf{K}}_{\mathrm{\theta }}^\Omega = {\mathbf{K}}{_{\mathrm{\theta }}^{\Omega {{\mathrm{disc}}}}}+ {\mathbf{K}}{_{\mathrm{\theta }}^{\Omega {{\mathrm{blade}}}}} \end{aligned}$$(A.18)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{K}}{_{\mathrm{\uptheta }}^{\Omega {{\mathrm{disc}}}}}= {J_{{\mathrm{pd}}}}{{\mathbf{\Psi }}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{\Psi }}\left( {{z_{\mathrm{d}}}} \right) \\ {\mathbf{K}}{_{\mathrm{\uptheta }}^{\Omega {{\mathrm{blade}}}}} = {N_{\mathrm{b}}}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{\Omega ^2}{{\left( {R_{\mathrm{d}} + x} \right) }^2}{{\mathbf{\Psi }}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\varvec{\Psi }}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{array} \right. \end{aligned}$$(A.19) -

(11)

\({\mathbf{K}}_{{{\mathrm{B}}_i}}^\Omega \) is the spin softening stiffness matrix caused by blade spinning and can be shown as follows

$$\begin{aligned}&{\mathbf{K}}_{{{\mathrm{B}}_i}}^\Omega = \left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{u}}i}^\Omega }&{}{}\\ {}&{}{{\mathbf{K}}_{{\mathrm{v}}i}^\Omega } \end{array}} \right] \end{aligned}$$(A.20)$$\begin{aligned}&\left\{ {\begin{array}{*{20}{l}} {{\mathbf{K}}_{{\mathrm{u}}i}^\Omega = {\Omega ^2}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\mathbf{U}}^{\mathrm{T}}}{\mathbf{U}}} \right] {\mathrm{d}}x} }\\ {{\mathbf{K}}_{{\mathrm{v}}i}^\Omega = {\Omega ^2}{\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\cos }^2}\left( \beta \right) {{\mathbf{V}}^{\mathrm{T}}}{\mathbf{V}}} \right] {\mathrm{d}}x} } \end{array}} \right. \end{aligned}$$(A.21) -

(12)

\({\mathbf{M}}_{{\mathrm{\theta B}}}\) is the static-coupling mass matrix between shaft and blade bending deformation and can be shown as follows

$$\begin{aligned}&{{\varvec{M}}_{{\mathrm{\theta B}}}}{{ = }}\left[ {\begin{array}{*{20}{c}} {{\varvec{M}}_{{\mathrm{\theta B}}}^u}&{{\varvec{M}}_{{\mathrm{\uptheta B}}}^v} \end{array}} \right] \end{aligned}$$(A.22)$$\begin{aligned}&\left\{ {\begin{array}{*{20}{l}} {{\varvec{M}}_{{\mathrm{\theta B}}}^u = {\mathbf{0}}}\\[10pt] {{\varvec{M}}_{{\mathrm{\theta B}}}^v = {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {\cos \left( \beta \right) \left( {R_{\mathrm{d}} + x} \right) {{\mathbf{V}}^{\mathrm{T}}}{\mathbf{\Psi }}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} } \end{array}} \right. \end{aligned}$$(A.23) -

(13)

\({\mathbf{G}}_{{\mathrm{\theta B}}}\) is the static-coupling gyroscopic matrix between shaft and blade bending deformation and can be shown as follows

$$\begin{aligned}&{\mathbf{G}}_{{\mathrm{\theta B}}}^{}{{ = }}\left[ {\begin{array}{*{20}{c}} {{\mathbf{G}}_{{\mathrm{\theta B}}}^u}&{{\mathbf{G}}_{{\mathrm{\theta B}}}^v} \end{array}} \right] \end{aligned}$$(A.24)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{G}}_{{\mathrm{\theta B}}}^u = {\mathrm{2}}\Omega {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {\left( {R_{\mathrm{d}} + x} \right) {{\varvec{\Psi }}^{\mathrm{T}}}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{U}}} \right] {\mathrm{d}}x} \\ {\mathbf{G}}_{{\mathrm{\theta B}}}^v = {\mathbf{0}} \end{array} \right. \end{aligned}$$(A.25) -

(14)

\({\mathbf{K}}_{{\mathrm{\theta B}}}^\Omega \) is the static-coupling stiffness matrix between shaft and blade bending deformation and can be shown as follows

$$\begin{aligned}&{\mathbf{K}}_{{\mathrm{\theta B}}}^\Omega {{ = }}\left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{\theta B}}}^{\Omega u} }&{{\mathbf{K}}_{{\mathrm{\theta B}}}^{\Omega v} } \end{array}} \right] \end{aligned}$$(A.26)$$\begin{aligned}&\left\{ \begin{array}{l} {\mathbf{K}}_{{\mathrm{\theta B}}}^{\Omega u} = {\mathbf{0}}\\ {\mathbf{K}}_{{\mathrm{\theta B}}}^{\Omega v} ={\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {\cos \left( \beta \right) {\Omega ^2}\left( {R_{\mathrm{d}} + x} \right) {{\mathbf{V}}^{\mathrm{T}}}{\mathbf{\Psi }}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x}\nonumber \end{array} \right. \\ \end{aligned}$$(A.27) -

(15)

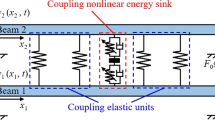

The dynamic coupling terms shown in Fig. 7 can be expressed with following forms:

$$\begin{aligned}&{{\varvec{M}}_{{\mathrm{S\theta }}}}={\left[ {\begin{array}{*{20}{c}} {{\varvec{M}}_{{\mathrm{S\theta }}}^x}&{{\varvec{M}}_{{\mathrm{S\theta }}}^y} \end{array}} \right] ^{\mathrm{T}}} = \cos \left( {\Omega t} \right) {{\varvec{M}}_{{\mathrm{S\theta }}}^c} + \sin \left( {\Omega t} \right) {{\varvec{M}}_{{\mathrm{S\theta }}}^s} \end{aligned}$$(A.28a)$$\begin{aligned}&{{\varvec{M}}_{{\mathrm{SB}}}}=\left[ {\begin{array}{*{20}{c}} {{\varvec{M}}_{{\mathrm{SB}}}^{ux}}&{}{{\varvec{M}}_{{\mathrm{SB}}}^{vx}}\\ {{\varvec{M}}_{{\mathrm{SB}}}^{uy}}&{}{{\varvec{M}}_{{\mathrm{SB}}}^{vy}} \end{array}} \right] = \cos \left( {{\theta _i}} \right) {\mathbf {M}}_{{\mathrm{SB}}}^c + {\mathrm{sin}}\left( {{\theta _i}} \right) {\mathbf {M}}_{{\mathrm{SB}}}^s \end{aligned}$$(A.28b)$$\begin{aligned}&{{\mathbf{G}}_{{\mathrm{SB}}}}=\left[ {\begin{array}{*{20}{c}} {{\mathbf{G}}_{{\mathrm{SB}}}^{ux}}&{}{{\mathbf{G}}_{{\mathrm{SB}}}^{vx}}\\ {{\mathbf{G}}_{{\mathrm{SB}}}^{uy}}&{}{{\mathbf{G}}_{{\mathrm{SB}}}^{vy}} \end{array}} \right] =2\Omega \cos \left( {{\theta _i}} \right) {\mathbf {G}}_{{\mathrm{SB}}}^c+2\Omega {\mathrm{sin}}\left( {{\theta _i}} \right) {\mathbf {G}}_{{\mathrm{SB}}}^s \end{aligned}$$(A.28c)$$\begin{aligned}&{{\mathbf{G}}_{{\mathrm{BS}}}}=\left[ {\begin{array}{*{20}{c}} {{\mathbf{G}}_{{\mathrm{BS}}}^{ux}}&{}{{\mathbf{G}}_{{\mathrm{BS}}}^{vx}}\\ {{\mathbf{G}}_{{\mathrm{BS}}}^{uy}}&{}{{\mathbf{G}}_{{\mathrm{BS}}}^{vy}} \end{array}} \right] =2\Omega \cos \left( {{\theta _i}} \right) {\mathbf {G}}_{{\mathrm{BS}}}^c+2\Omega {\mathrm{sin}}\left( {{\theta _i}} \right) {\mathbf {G}}_{{\mathrm{BS}}}^s \end{aligned}$$(A.28d)$$\begin{aligned}&{{\mathbf{K}}_{{\mathrm{SB}}}}=\left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{SB}}}^{ux}}&{}{{\mathbf{K}}_{{\mathrm{SB}}}^{vx}}\\ {{\mathbf{K}}_{{\mathrm{SB}}}^{uy}}&{}{{\mathbf{K}}_{{\mathrm{SB}}}^{vy}} \end{array}} \right] =\Omega ^2 \cos \left( {{\theta _i}} \right) {\mathbf {K}}_{{\mathrm{SB}}}^c+\Omega ^2 {\mathrm{sin}}\left( {{\theta _i}} \right) {\mathbf {K}}_{{\mathrm{SB}}}^s \end{aligned}$$(A.28e)$$\begin{aligned}&{{\mathbf{K}}_{{\mathrm{BS}}}}=\left[ {\begin{array}{*{20}{c}} {{\mathbf{K}}_{{\mathrm{BS}}}^{ux}}&{}{{\mathbf{K}}_{{\mathrm{BS}}}^{vx}}\\ {{\mathbf{K}}_{{\mathrm{BS}}}^{uy}}&{}{{\mathbf{K}}_{{\mathrm{BS}}}^{vy}} \end{array}} \right] =\Omega ^2 \cos \left( {{\theta _i}} \right) {\mathbf {K}}_{{\mathrm{BS}}}^c+\Omega ^2 {\mathrm{sin}}\left( {{\theta _i}} \right) {\mathbf {K}}_{{\mathrm{BS}}}^s \end{aligned}$$(A.28f)where, the superscript ‘\(^\mathrm{s}\)’ and ‘\(^\mathrm{c}\)’ denote that the coefficients are corresponding to the “cos” and “sin” part, respectively. Considering the relationship \(X_i(z)=Y_i(z)\), those coefficients can be expressed as

$$\begin{aligned}&{{\varvec{M}}_{{\mathrm{S\uptheta }}}^c} = {\left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{ - {\mathbf{C}}_{{\mathrm{S\theta }}}^1} \end{array}} \right] ^{\mathrm{T}}},&{{\varvec{M}}_{{\mathrm{S\theta }}}^s}&= {\left[ {\begin{array}{*{20}{c}} {{\mathbf{C}}_{{\mathrm{S\theta }}}^1}&{\mathbf{0}} \end{array}} \right] ^{\mathrm{T}}}\end{aligned}$$(A.29a)$$\begin{aligned}&{\mathbf {M}}_{{\mathrm{SB}}}^c = \left[ {\begin{array}{*{20}{c}} {{\mathbf{C}}_{{\mathrm{SB}}}^1}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^2}\\ {\mathbf{0}}&{}{{\mathbf{C}}_{{\mathrm{SB}}}^3} \end{array}} \right] ,&{\mathbf {M}}_{{\mathrm{SB}}}^s&= \left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^3}\\ {{\mathbf{C}}_{{\mathrm{SB}}}^1}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^2} \end{array}} \right] \end{aligned}$$(A.29b)$$\begin{aligned}&{\mathbf {G}}_{{\mathrm{SB}}}^c = \left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^3}\\ {{\mathbf{C}}_{{\mathrm{SB}}}^1}&{}{\mathbf{0}} \end{array}} \right] ,&{\mathbf {G}}_{{\mathrm{SB}}}^s&= \left[ {\begin{array}{*{20}{c}} { - {\mathbf{C}}_{{\mathrm{SB}}}^1}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^3} \end{array}} \right] \end{aligned}$$(A.29c)$$\begin{aligned}&{\mathbf {G}}_{{\mathrm{BS}}}^c =\left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^2} \end{array}} \right] ,&{\mathbf {G}}_{{\mathrm{BS}}}^s&=\left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{\mathbf{0}}\\ {{\mathbf{C}}_{{\mathrm{SB}}}^2}&{}{\mathbf{0}} \end{array}} \right] \end{aligned}$$(A.29d)$$\begin{aligned}&{\mathbf {K}}_{{\mathrm{SB}}}^c =\left[ {\begin{array}{*{20}{c}} { - {\mathbf{C}}_{{\mathrm{SB}}}^1}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{ - {\mathbf{C}}_{{\mathrm{SB}}}^3} \end{array}} \right] ,&{\mathbf {K}}_{{\mathrm{SB}}}^s&= \left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{{\mathbf{C}}_{{\mathrm{SB}}}^3}\\ { - {\mathbf{C}}_{{\mathrm{SB}}}^1}&{}{\mathbf{0}} \end{array}} \right] \end{aligned}$$(A.29e)$$\begin{aligned}&{\mathbf {K}}_{{\mathrm{BS}}}^c =\left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{\mathbf{0}}\\ {{\mathbf{C}}_{{\mathrm{SB}}}^2}&{}{\mathbf{0}} \end{array}} \right] ,{\mathrm{}}&{\mathbf {K}}_{{\mathrm{SB}}}^s{\mathrm{}}&=\left[ {\begin{array}{*{20}{c}} {\mathbf{0}}&{}{\mathbf{0}}\\ {\mathbf{0}}&{}{{\mathbf{C}}_{{\mathrm{SB}}}^2} \end{array}} \right] \end{aligned}$$(A.29f)with

$$\begin{aligned} {{\mathbf{C}}_{{\mathrm{S\theta }}}^{1} = {m_{\mathrm{e}}}e{\varvec{\Phi }}\left( {{z_{\mathrm{d}}}} \right) {\mathbf{Y}}\left( {{z_{\mathrm{d}}}} \right) } \end{aligned}$$(A.30)and

$$\begin{aligned}&{\mathbf {C}}_{{\mathrm{SB}}}^{1} = {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {{{\mathbf {U}}^{\mathrm{T}}}{\mathbf {X}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{aligned}$$(A.31a)$$\begin{aligned}&{\mathbf {C}}_{{\mathrm{SB}}}^{2} = {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ { \sin \left( \beta \right) \left( {{R_{\mathrm{d}}} + x} \right) {{\mathbf {V}}^{\mathrm{T}}}{\mathbf {X'}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{aligned}$$(A.31b)$$\begin{aligned}&{\mathbf {C}}_{{\mathrm{SB}}}^{3} = {\rho _{\mathrm{b}}}{A_{\mathrm{b}}}\displaystyle \int _{\mathrm{0}}^{{L_{\mathrm{b}}}} {\left[ {\cos \left( \beta \right) {{\mathbf {V}}^{\mathrm{T}}}{\mathbf {Y}}\left( {{z_{\mathrm{d}}}} \right) } \right] {\mathrm{d}}x} \end{aligned}$$(A.31c)

Rights and permissions

About this article

Cite this article

Yang, LH., Mao, Z., Wu, SM. et al. Steady-state coupling vibration analysis of shaft–disk–blade system with blade crack. Nonlinear Dyn 105, 61–98 (2021). https://doi.org/10.1007/s11071-021-06645-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-021-06645-3