Abstract

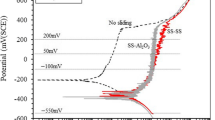

Corrosive wear involves interaction of electrochemical and mechanical processes. The synergism of these two processes often results in significant material loss, compared to those caused by individual processes. Reduction of either corrosion or wear may effectively decrease material loss under certain circumstances. Since cathodic protection can reduce corrosion of metallic materials, it may also diminish corrosive wear if the corrosion process is suppressed. However, under a cathodic potential (potentiostatic condition) or enforced current (galvanosatic condition), properties of a material could be affected and thus its corrosive wear behavior could be different from what is expected. The present research demonstrated that cathodic protection under potentiostatic condition was beneficial under low wearing force but it became ineffective under higher wearing forces or more negative cathodic potentials. Hydrogen embrittlement could be responsible for this change.

Similar content being viewed by others

References

SW Watson FJ Friedersdorf BW Madsen SD Cramer (1995) Wear 181--183 476–484

EJ Wentzel C Allen (1995) Wear 181--183 63–69

S. Mischler, S. Debaud and D. Landolt, Wear of Engineering Materials, Conference Proceedings from Materials Solutions (97), Jeffrey A. Hawk (ed). pp. 157–164.

M. Joseph S.P. Steigerwald R.S. Murarka (1997) Gutmann Chemical Mechanical Planarization of Microelectronic Materials Wiley-Interscience New York

WJ Schumacher (1993) Mater. Perfor. 23 IssueID7 50–53

W.J. Schumacher, Wear of Materials (Vancouver, 1985, ASME, New York, 1985) pp. 558–566.

P. Jemmely S. Mischler D. Landolt (1999) Tribol Int. 32 295–303

SW Watson FJ Friedersdorf BW Madsen (1995) Wear 181--183 476–484

H. Abd-el-Kader S.M. El-Raghy (1986) Corrosion Sci. 26 647

L. Xia-xia D. Shizhuo Chenitan L Ming (1989) Wear 129 293

Y.L. Huang X.X. Jiang S.Z. Li (2000) Bull. Mater. Sci. 23 539

B.W. Madsen, ASTM G119–93, 1994, Ann. Book ASTM vol. 03.02. Wear and corrosion, ASTM, Philadelphia, PA, 1994, 507–512.

SW Watson BW Madsen SD Cramer (1995) Wear 181--183 469–475

D.A. Jones (1992) Principles and Prevention of Corrosion Macmillian Publishing Company NY

CA Zaffe CE Sims (1940) Hydrogen, Flakes and Shatter cracks II IssueID5 145–151

M. Szczepanski, The Brittleness of Steel, John Wiley & Sons, Inc. pp. 188.

M.R. Louthan, Jr. et al., Hydrogen Damage, Cedric D. Beachem (ed.) A Metal Science Source Book, ASM (1977), pp. 289–300.

Yanliang et al. (2002) Bull. Mater. Sci. 26 IssueID4 431–434

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akonko, S., Li, D.Y. & Ziomek-Moroz, M. Effects of cathodic protection on corrosive wear of 304 stainless steel. Tribol Lett 18, 405–410 (2005). https://doi.org/10.1007/s11249-004-3205-1

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11249-004-3205-1