Abstract

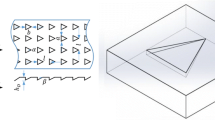

Micro-scale textures may be engineered into surfaces for lubrication performance improvement. It is expected that a carefully chosen texture helps retain lubricant and enhances the hydrodynamic effect at the interface. The concept of model-based virtual texturing enables textured surfaces to be generated and “tested” through numerical simulations. This paper reports virtual texturing and simulation of a group of textured surfaces in a lubricated concentrated contact. The focus of the study is on the selection of texture distribution patterns based on their lubrication performance. Patterns of fishbone, sinusoidal, triangular, and honeycomb distributions have been investigated. The effects of texture direction, orientation angle, feature continuity, and aspect ratio are also studied. The results indicate that, for the given material and geometry system under the given conditions in the present work, the textures generating the strongest hydrodynamic lifting are short grooves with a small aspect ratio and sinusoidal waves of a small wavelength/amplitude ratio propagating in the motion direction.

Similar content being viewed by others

References

Hector, L.G., Sheu, S.: Forced energy beam work roll surface texturing science and technology. J. Mater. Process. Manuf. Technol. 2, 63–117 (1993)

Etsion, I., Kligerman, Y., Halperin, G.: Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 42, 511–516 (1999)

Etsion, I.: Improving tribological performance of mechanical seals by laser surface texturing. Proceedings of the 17th International Pump Users Symposium, pp. 17–22 (2000)

Wang, X., Kato, K., Adachi, K., Aizawa, K.: The effect of laser texturing of SiC surface on the critical load for the transition of water lubrication mode from hydrodynamic to mixed. Triol. Int. 34, 703–711 (2001)

Kligerman, Y., Etsion, I.: Analysis of the hydrodynamic effects in a surface textured circumferential gas seal. Tribol. Trans. 44, 472–478 (2001)

Etsion, I.: State of the art in laser surface texturing. ASME J. Tribol. 127(1), 248–253 (2005)

Brizmer, V., Kligerman, Y., Etsion, I.: A laser surface textured parallel thrust bearing. Tribol. Trans. 46, 397–403 (2003)

Pride, S., Folkert, K., Guichelaar, P., Etsion, I.: Effect of micro-surface texturing on breakaway torque and blister formation on carbon-graphite faces in a mechanical seal. Lubr. Eng. 58(10), 16–21 (2002)

Wakuda, M., Yamauchi, Y., Kanzaki, S., Yasuda, Y.: Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254, 356–363 (2003)

Tanaka, H., Gomi, K., Miyake, Y.: Micro-tribology of carbon-coated thin film media with well-defined surface texture. IEEE Trans. Magn. 29(1), 270–275 (1993)

Pettersson, U., Jacobson, S.: Textured surfaces for improved lubrication at high pressure and low sliding speed of roller/piston in hydraulic motors. Tribol. Int. 40, 355–359 (2007)

Wang, X., Kato, K., Adachi, K., Aizawa, K.: Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol. Int. 36(3), 189–197 (2002)

Wang, X., Kato, K., Adachi, K.: The lubrication effect of micro-pits on parallel sliding faces of sic in water. Lubr. Eng. 58(8), 27–34 (2002)

Wang, Q., Zhu, D.: Virtual texturing: modeling the performance of lubricated contacts of engineered surfaces. J. Tribol. 127, 722–728 (2005)

Hu, Y.Z., Zhu, D.: A full numerical solution to the mixed lubrication in point contacts. J. Tribol. 122, 1–9 (2000)

Zhu, D., Hu, Y.Z.: A computer program package for the prediction of EHL and mixed lubrication characteristics, friction, subsurface stresses and flash temperatures based on measured 3-D surface roughness. Tribol. Trans. 44, 383–390 (2001)

Liu, Y., Wang, Q., Hu, Y., Wang, W., Zhu, D.: Effects of differential schemes and mesh density on EHL film thickness in point contacts. J. Tribol. 128, 641–653 (2006)

Zhu, D.: On some aspects in numerical solution of thin-film and mixed EHL. To appear in J. Eng. Tribol. (2007)

Kovalchenko, A., Ajayi, O., Erdemir, A., Fenske, G., Etsion, I.: The effect of laser texturing of steel surfaces and speed-load parameters on the transition of lubrication regime from boundary to hydrodynamic. Tribol. Trans. 47, 299–307 (2004)

Mourier, L., Mazuyer, D., Lubrecht, A.A., Donner, C.: Transient increase of film thickness in micro-textured EHL contacts. Tribol. Int. 39, 1745–1756 (2006)

Hartl, I.K.: The effect of surface texturing on thin EHL lubrication films. Tribol. Int. 40, 1100–1110 (2006)

Voevodin, A.A., Zabinski, J.S.: Laser surface texturing for adaptive solid lubrication. Wear 261, 1285–1292 (2006)

Dowson, D., Higginson, G.R.: Elastohydrodynamic Lubrication. Pergamon Press (1966)

Liu, Y., Wang, Q., Zhu, D., Wang, W., Hu, Y.: Effects of differential scheme and viscosity model on rough-surface point-contact isothermal EHL. Submitted to J. Tribol. (2007)

Liu, S.B., Wang, Q., Liu, G.: A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 243(1–2), 101–110 (2000)

Wang, W.Z., Wang, H., Liu Y.C., Hu, Y.Z., Zhu, D.: A comparative study of the methods for calculation of surface elastic deformation. Proc. ImechE, Part J, J. Eng. Tribol. 217, 145–153 (2003)

Pinkus, O., Sternlicht, B.: Theory of Hydrodynamic Lubrication. McGraw-Hill, Inc (1961)

Costa, H.L., Hutchings, I.M.: Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 40, 1227–1238 (2007)

Acknowledgments

The authors would like to thank Nissan Motors for research support and permission to publish the results.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, N., Nanbu, T., Yasuda, Y. et al. Micro Textures in Concentrated-Conformal-Contact Lubrication: Effect of Distribution Patterns. Tribol Lett 28, 275–285 (2007). https://doi.org/10.1007/s11249-007-9271-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-007-9271-4