Abstract

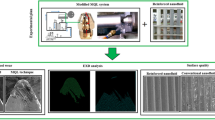

Several health and environmental related issues caused by the application of traditional cutting fluids in machining can be solved by implementing eco-friendly technologies such as minimum quantity lubrication (MQL). Moreover, nanofluid MQL has been proposed to enhance the cooling/lubricating properties of pure MQL and displays significantly good results for machinability. However, the mechanism on compatibility of nanoparticles with cutting fluids has not been explored. In this study, nanoparticles with different hardness and vegetable oils with different viscosity were selected for nanofluids preparation. The end milling experiments were carried out on 7050 material by applying MQL with particularly prepared nanofluids. The cutting force and surface roughness were measured corresponding to the machining performance. The compatibility of hardness of nanoparticles with viscosity of base fluids has been evaluated, and the mechanism has been analyzed by new-designed tribology tests. Results show that canola oil-based diamond nanofluids MQL exhibit the lowest cutting force and natural77 oil-based diamond nanofluids perform the lowest surface roughness with reduction of 10.71 and 14.92%, respectively, compared to dry machining condition. The research is novel and contributes to the machining of such materials at the industry level.

Similar content being viewed by others

References

Lawal, S.A., Imtiaz, A.C., Yusoff, N.: A critical assessment of lubrication techniques in machining processes: a case for minimum quantity lubrication using vegetable oil-based lubricant. J. Clean. Prod. 41, 210–221 (2013)

Chetan, S.G., Venkateswara, P.: R.: Application of sustainable techniques in metal cutting for enhanced machinability: a review. J. Clean. Prod. 100, 17–34 (2015)

Yuan, S.M., Yan, L.T., Liu, W.D.: Effects of cooling air temperature on cryogenic machining of Ti–6Al–4V alloy. J. Mater. Process. Technol. 211(3), 356–362 (2011)

Benjamin, D.M., Sabarish, V.N., Hariharan, M.V.: On the benefits of sub-zero air supplemented minimum quantity lubrication systems: An experimental and mechanistic investigation on end milling of Ti-6-Al-4-V alloy. Tribol. Int. 119, 464–473 (2018)

Sartori, S., Ghiotti, A., Bruschi, S.: Hybrid lubricating/cooling strategies to reduce the tool wear in finishing turning of difficult-to-cut alloys. Wear. 376, 107–114 (2017)

Huang, S., Lv, T., Wang, M.: Enhanced machining performance and lubrication mechanism of electrostatic minimum quantity lubrication-EMQL milling process. Int. J. Adv. Manuf. Technol. 94(1–4), 655–666 (2018)

Revuru, R.S., Zhang, J.Z., Posinasetti, N.R.: Optimization of titanium alloys turning operation in varied cutting fluid conditions with multiple machining performance characteristics. Int. J. Adv. Manuf. Technol. 95(1–4), 1451–1463 (2018)

Yuan, S.M., Hou, X.B., Zhu, G.Y.: A novel approach of applying copper nanoparticles in minimum quantity lubrication for milling of Ti-6Al-4V. Adv. Prod. Eng. Manag. 12(2), 139 (2017)

Singh, R.K., Dixit, A.R., Mandal, A.: Emerging application of nanoparticle-enriched cutting fluid in metal removal processes: a review. J. Braz. Soc. Mech. Sci. Eng. 39(11), 4677–4717 (2017)

Shokoohi, Y., Shekarian, E.: Application of nanofluids in machining processes-a review. J. Nanosci. Technol. 2, 59–63 (2015)

Park, K.H., Ewald, B., Kwon, P.Y.: Effect of nano-enhanced lubricant in minimum quantity lubrication balling milling. J. Tribol. 133(3), 031803 (2011)

Zhang, Y., Li, C., Yang, M.: Experimental evaluation of cooling performance by friction coefficient and specific friction energy in nanofluid minimum quantity lubrication grinding with different types of vegetable oil. J. Clean. Prod. 139, 685–705 (2016)

Su, Y., Gong, L., Li, B.: Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int. J. Adv. Manuf. Technol. 83(9–12), 2083–2089 (2016)

Godlevski, V.A., Volkov, A.V., Latyshev, V.N.: A description of the lubricating action of the tribo-active components of cutting fluids. Lubr. Sci. 11(1), 51–62 (1998)

Itoigawa, F., Childs, T.H.C., Nakamura, T.: Effects and mechanisms in minimal quantity lubrication machining of an aluminum alloy. Wear 260(3), 339–344 (2006)

Ejim, C.E., Rahman, M.A., Amirfazli, A.: Effects of liquid viscosity and surface tension on atomization in two-phase, gas/liquid fluid coker nozzles. Fuel 89(8), 1872–1882 (2010)

Ni, J., Feng, G., Meng, Z.: Reinforced lubrication of vegetable oils with graphene additive in tapping ADC12 aluminum alloy. Int. J. Adv. Manuf. Technol. 94(1–4), 1031–1040 (2018)

Srikant, R.R., Ramana, V.: Performance evaluation of vegetable emulsifier based green cutting fluid in turning of American Iron and Steel Institute (AISI) 1040 steel–an initiative towards sustainable manufacturing. J. Clean. Prod. 108, 104–109 (2015)

Raza, S.W., Salman, P., Ibrahim, D.: Tool wear patterns when turning of titanium alloy using sustainable lubrication strategies. Int. J. Precis. Eng. Manuf. 15(9), 1979–1985 (2014)

Padmini, R., Vamsi Krishna, P., Krishna Mohana Rao, G.: Effectiveness of vegetable oil based nanofluids as potential cutting fluids in turning AISI 1040 steel. Tribol. Int. 94, 490–501 (2016)

Xuan, Y., Qiang, L.: Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 21(1), 58–64 (2000)

Zhang, M., Wang, X., Liu, W.: Performance and anti-wear mechanism of Cu nanoparticles as lubricating oil additives. Ind. Lubr. Tribol. 61(6), 311–318 (2009)

Wu, Y.Y., Tsui, W.C., Liu, T.C.: Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear. 262(7–8), 819–825 (2007)

Lee, K., Hwang, Y., Cheong, S.: Understanding the role of nanoparticles in nano-oil lubrication. Tribol. Lett. 35(2), 127–131 (2009)

Choi, C., Jung, M., Choi, Y.: Tribological properties of lubricating oil-based nanofluids with metal/carbon nanoparticles. J. Nanosci. Nanotechnol. 11(1), 368 (2011)

Guo, S., Li, C., Zhang, Y.: Analysis of volume ratio of castor/soybean oil mixture on minimum quantity lubrication grinding performance and microstructure evaluation by fractal dimension. Ind. Crops Prod. 111, 494–505 (2018)

Luan, G., Qian, Z.: Friction and wear characteristics of water-based ZnO and Al2O3 nanofluids. Tribol. Trans. 55(3), 345–350 (2012)

Shin, J., Kim, T., Kim, D.E.: Castability and mechanical properties of new 7xxx aluminum alloys for automotive chassis/body applications. J. Alloys Compd. 698, 577–590 (2017)

Sang, D., Fu, R., Li, Y.: Combined deformation behavior and microstructure evolution of 7050 aluminum alloy during hot shear-compression deformation. Mater. Charact. 122, 154–161 (2016)

Chen, L., Xie, H., Li, Y.: Nanofluids containing carbon nanotubes treated by mechanochemical reaction. Thermochim. Acta 477(1), 21–24 (2008)

Sharma, A.K., Tiwari, A.K., Dixit, A.R.: Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribol. Int. 119, 99–111 (2018)

Acknowledgements

This project is supported by National Natural Science Foundation of China (Grant No. 51475030). The authors are indebted to this financial support to accomplish this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, S., Hou, X., Wang, L. et al. Experimental Investigation on the Compatibility of Nanoparticles with Vegetable Oils for Nanofluid Minimum Quantity Lubrication Machining. Tribol Lett 66, 106 (2018). https://doi.org/10.1007/s11249-018-1059-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1059-1