Abstract

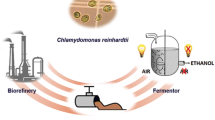

In a cycle tubular photobioreactor, Chlorella pyrenoidosa was cultured in undiluted wastewater from ethanol fermentation using cassava powder as raw material. The results showed that the optimum cultivation conditions were initial pH of 6.0, temperature at 27°C, continuous illumination at 3,000 lux, and cycle speed of 110 ml min−1. Under these optimum conditions, after the logarithmic phase of batch cultivation with wastewater of pH 6.0, the reactor could be continuously operated with natural pH wastewater (3.8) as feed solution. By a dilution ratio of 0.17 day−1, it could be operated stably for over 30 days in continuous cultivation. pH, removal rate of chemical oxygen demand, and biomass (cell dry weight) concentration ranged from 6.22 to 6.47, 72.21 to 76.32% and 3.55 to 3.73 g l−1, respectively. After treatment, the wastewater could be used again in the process of ethanol fermentation.

Similar content being viewed by others

References

APHA, AWW, WPCF (1992) Standard methods for the examination of water and wastewater, 17th edn. Diaz de Santos, Madrid

Borowitzka MA, Borowitzka LJ (1988) Microalgal biotechnology. Cambridge University Press, Cambridge

Canizares-Villanueva RO, Dominguez AR, Cruz MS, Rios-Leal E (1995) Chemical composition of cyanobacteria grown in diluted aerated swine wastewater. Bioresour Technol 51:111–116. doi:10.1016/0960-8524(94)00099-M

Ding Z-y, Wang Y-h, Zhang L, Shi G-y, Zhang K-c (2003) Study on recycling the filtrate of distillage filtrated by membrane. Liquor Mak 30:61–63 (in Chinese)

Goldman JC, Carpenter EJ (1974) A kinetic approach to the effect of temperature on algal growth. Limnol Oceanogr 19:756–766

Gong X-d, Chen F (1997) Optimisation of culture medium for growth of Haematococcus pluvialis. J Appl Phycol 9:437–444. doi:10.1023/A:1007944922264

Hu Y-y, Wu C-f, Ye W-s, Cen C-p (1998) A preliminary study on solid–liquid separation of waste distillers from alcohol production with dry cassava. Res Environ Sci 11:45–48 (in Chinese)

Martinez F, Orus MI (1991) Interactions between glucose and inorganic carbon metabolism in Chlorella vulgaris strain UAM 101. Plant Physiol 95:1150–1155

Myers J (1953) Growth characteristics of algae in relation to the problems of mass culture. In: Burlew JS (ed) Algal culture—from laboratory to pilot plant. The Kirby Lithographic Company Inc, Washington, D.C

Ogbonna JC, Masui H, Tanaka H (1997) Sequential heterotrophic/autotrophic cultivation—an efficient method of producing Chlorella biomass for health food and animal feed. J Appl Phycol 9:359–366. doi:10.1023/A:1007981930676

Pirt SJ, Lee YK, Walach MR, Pirt MW, Balyuzi HH, Bazin MJ (1983) A tubular bioreactor for photosynthetic production of biomass from carbon dioxide: design and performance. J Chem Technol Biotechnol 33B:35–58

Scragg AH, Illman AM, Carden A, Shales SW (2002) Growth of microalgae with increased calorific values in a tubular bioreactor. Biomass Bioenergy 23:67–73. doi:10.1016/S0961-9534(02)00028-4

Shi X-m, Zhang X-w, Chen F (2000) Heterotrophic production of biomass and lutein by Chlorella protothecoides on various nitrogen sources. Enzyme Microb Technol 27:312–318. doi:10.1016/S0141-0229(00)00208-8

Sorokin C (1959) Tabular comparative data for the low-and high-temperature strains of Chlorella. Nature 184:613–614. doi:10.1038/184613a0

Travieso L, Hall DO, Rao KK, Benitez F, Sanchez E, Borja R (2001) A helical tubular photobioreactor producing Spirulina in a semicontinuous mode. Int Biodeterior Biodegradation 47:151–155. doi:10.1016/S0964-8305(01)00043-9

Valderrama LT, Campo CMD, Rodriguez CM, de-Bashan LE, Bashan Y (2002) Treatment of recalcitrant wastewater from ethanol and citric acid production using the microalga Chlorella vulgaris and the macrophyte Lemna minuscula. Water Res 36:4185–4192. doi:10.1016/S0043-1354(02)00143-4

Villasclaras SS, Sancho MEM, Caballero MTE, Perez AD (1996) Production of microalgae from olive mill wastewater. Int Biodeterior Biodegradation 38:245–247. doi:10.1016/S0964-8305(96)00057-1

Walter C, Steinau T, Gerbsch N, Buchholz R (2003) Monoseptic cultivation of phototrophic microorganisms-development and scale-up of a photobioreactor system with thermal sterilization. Biomolecul Eng 20:261–271. doi:10.1016/S1389-0344(03)00068-6

Watanabe Y, Saiki H (1997) Development of a photobioreactor incorporating Chlorella sp. for removal of CO2 in stack gas. Energy Conserv Manage 38(suppl):S499–S503. doi:10.1016/S0196-8904(96)00317-2

Zhang K-c, Fan Z-h (1989) Ethanol production technics of recycling lees filtrate (in Chinese). State intellectual property office of P.R.C 88101404.4, China

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Cf., Ding, Zy. & Zhang, Kc. Growth of Chlorella pyrenoidosa in wastewater from cassava ethanol fermentation. World J Microbiol Biotechnol 24, 2919–2925 (2008). https://doi.org/10.1007/s11274-008-9833-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-008-9833-0