Abstract

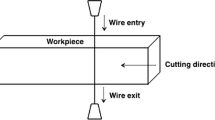

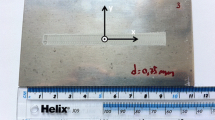

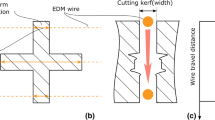

The multiple cut contour method is applied to map longitudinal and transverse components of residual stress in two nominally identical 50 mm thick electron beam welded Ti-6Al-4V alloy plates, one in the as-welded condition and a second welded plate in a post weld heat treated (PWHT) condition. The accuracy and resolution of the contour method results are directly linked to the quality of the electro-discharge machining cut made. Two symmetric surface contour artefacts associated with cutting titanium, surface bowing and a flared edge, are identified and their influence on residual stresses calculated by the contour method is quantified. The former artefact is controlled by undertaking a series of cutting trials with reduced power settings to find optimal cutting conditions. The latter is mitigated by attaching 5 mm thick sacrificial plates to the wire exit side of the test specimen. The low level of noise in the measured stress profiles for both the as-welded and PWHT plates demonstrates the importance of controlling the quality of a contour cut and the added value of undertaking cutting trials.

Similar content being viewed by others

References

Boyer R, Welsch G, Collings EW (eds) (1994) Materials properties handbook:titanium alloys. ASM International, Materials Park, OH

Boyer R (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng, A 213(1–2):103–114

Balasubramanian TS, Balasubramanian V, Muthumanikkam MA (2011) Fatigue performance of gas tungsten arc, electron beam and laser beam welded Ti-6Al-4V alloy joints. J Mater Eng Perform 20(9):1620–1630

Messler RW Jr (1981) Electron beam weldability of advanced titanium alloys. Weld J 60(5):79–84

Lancaster J (1992) Handbook of structural welding. Woodhead Publishing Ltd., Abington, Cambridge, United Kingdom

Schults H (1993) Electron beam welding. Abington Publishing, Cambridge, United Kingdom

Stone HJ, Withers PJ, Roberts SM, Reed RC, Holden TM (1999) Comparison of three different techniques for measuring the residual stresses in an electron beam-welded plate of WASPALOY. Metall Mater Trans A 30(7):1797–1808

Liu C, Wu B, Zhang JX (2010) Numerical investigation of residual stress in thick titanium alloy plate joined with electron beam welding. Metall Mater Trans B 41B:1129–1138

Fitzpatrick ME, Lodini A (eds) (2003) Analysis of residual stress by diffraction using neutron and synchrotron radiation. Taylor & Francis, London

Withers PJ, Preuss M, Steuwer A, Pang WL (2007) Methods for obtaining the strain-free lattice parameter when using diffraction to determine residual stress. J Appl Crystallogr 40:891–904

Hosseinzadeh F, Smith DJ, Truman CE (2009) Through thickness residual stresses in large rolls and sleeves for the metal working industry. Mater Sci Technol 25(7):862–873

Leggatt RH, Smith DJ, Smith SD, Faure F (1996) Development and experimental validation of the deep hole method for residual stress measurement. J Strain Anal Eng Des 31(3):177–186

Prime MB (2001) Cross-sectional mapping of residual stresses by measuring the surface contour after a cut. J Eng Mater Technol 123(2):162–168

Prime MB (2011) Contour method advanced applications: hoop stresses in cylinders and discontinuities. In: Proulx T (ed) Engineering application of residual stress, the society for experimental mechanics, pp 13–28

Prime MB, Hill MR, DeWald AT, Sebring RJ, Dave VR, Cola MJ (2002) Residual stress mapping in welds using the contour method. In: Proceedings of the 6th International Conference: Trends in Welding Research, April 15–19, pp 891–896

Traore Y, Bouchard PJ, Francis JA, Hosseinzadeh F (2011) A novel cutting strategy for reducing plasticity induced errors in residual stress measurements made with the contour method. Paper presented at the American Society of Mechanical Engineers, Pressure Vessels and Piping Division (Publication) PVP, Proceedings of the ASME Pressure Vessels and Piping Conference - Materials and Fabrication, Baltimore, USA

Zhang Y, Ganguly S, Edwards L, Fitzpatrick ME (2004) Cross-sectional mapping of residual stresses in a VPPA welde using the contour method. Acta Mater 52:5225–5232

Hosseinzadeh F, Toparli MB, Bouchard PJ (2012) Slitting and contour method residual stress measurements in an edge welded beam. J Pressure Vessel Technol 134(1)

DeWald AT, Hill MR (2006) Multi-axial contour method for mapping residual stresses in continuously processed bodies. Exp Mech 46(4):473–490

Kartal ME, Liljedahl CDM, Gungor S, Edwards L, Fitzpatrick ME (2008) Determination of the profile of the complete residual stress tensor in a VPPA weld using the multi-axial contour method. Acta Mater 56:4417–4428

Pagliaro P, Prime MB, Swenson H, Zuccarello B (2010) Measuring multiple residual-stress components using the contour method and multiple cuts. Exp Mech 50(2):187–194

Pagliaro P, Prime MB, Robinson JS, Clausen B, Swenson H, Steinzig M, Zuccarello B (2011) Meausring inaccessible residual streses using multiple methods and superposition. Exp Mech 51(7):1123–1134

Hosseinzadeh F, Bouchard PJ (2012) Mapping multiple components of residual stress tensor in a large P91 steel pipe girth weld using a single contour cut. Exp Mech. doi:10.1007/s11340-012-9627-z

Prime MB, Sebring RJ, Edwards JM, Hughes DJ, Webster PJ (2004) Laser surface-contouring and spline data-smoothing for residual stress measurement. Exp Mech 44(2):176–184

Prime MB, Kastengren AL (2010) The contour method cutting assumption: error minimization and correction. In: SEM Annual Conference, Indianapolis, Indiana, 7–10 June

Cheng W, Gremaud M, Finnie I, Prime MB (1994) Measurement of near surface residual stresses using electric discharge wire machining. J Eng Mater Technol 116:1–7

ABAQUS (2010) ABAQUS/Standard Documentation Version 6.10.2, ABAQUS Inc

Private communication with GF Agie Charmilles (2012)

Cho JR, Conlon KT, Reed RC (2003) Residual stresses in an electron beam weld of Ti-834: characterisation and numerical modelling. Metall Mater Trans A 34:2935–2946

Acknowledgements

P J Bouchard was supported by a Royal Society Industry Fellowship. This paper is published with the permission of BAMTRI.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseinzadeh, F., Ledgard, P. & Bouchard, P.J. Controlling the Cut in Contour Residual Stress Measurements of Electron Beam Welded Ti-6Al-4V Alloy Plates. Exp Mech 53, 829–839 (2013). https://doi.org/10.1007/s11340-012-9686-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-012-9686-1