Abstract

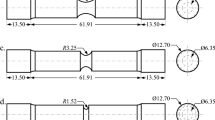

A tubular tension-torsion specimen is proposed to characterize the onset of ductile fracture in bulk materials at low stress triaxialities. The specimen features a stocky gage section of reduced thickness. The specimen geometry is optimized such that the stress and strain fields within the gage section are approximately uniform prior to necking. The stress state is plane stress while the circumferential strain is approximately zero. By applying different combinations of tension and torsion, the material response can be determined for stress triaxialities ranging from zero (pure shear) to about 0.58 (transverse plane strain tension), and Lode angle parameters ranging from 0 to 1. The relative displacement and rotation of the specimen shoulders as well as the surface strain fields within the gage section are determined through stereo digital image correlation. Multi-axial fracture experiments are performed on a 36NiCrMo16 high strength steel. A finite element model is built to determine the evolution of the local stress and strain fields all the way to fracture. Furthermore, the newly-proposed Hosford-Coulomb fracture initiation model is used to describe the effect of stress state on the onset of fracture.

Similar content being viewed by others

Notes

It is worth noting that Mohr and Henn [7] addressed this issue by reporting the loading paths for all elements within the specimen gage section, knowing that at least one of the reported paths must have led to the onset of fracture.

References

Barsoum I, Faleskog J (2007) Rupture mechanisms in combined tension and shear – experiments. Int J Solids Struct 44:1768–1786

Nahshon K, Hutchinson JW (2008) Modification of the Gurson Model for shear failure. Eur J Mech A/Solids 27:1–17

Bai YL, Wierzbicki T (2010) Application of extended Mohr-Coulomb criterion to ductile fracture. Int J Fract 161:1–20

Nielsen KL, Tvergaard V (2011) Failure by void coalescence in metallic materials containing primary and secondary voids subject to intense shearing. Int J Solids Struct 48:1255–1267

Danas K, Ponte Castañeda P (2012) Influence of the Lode parameter and the stress triaxiality on the failure of elasto-plastic porous materials. Int J Solids Struct 49(11–12):1325–1342

Dunand M, Mohr D (2013) Effect of lode parameter on plastic flow localization at low stress triaxialities, submitted for publication.

Mohr D, Henn S (2007) Calibration of stress-triaxiality dependent crack formation criteria: a new hybrid experimental-numerical method. Exp Mech 47:805–820

Teng X, Mae H, Bai Y, Wierzbicki T (2009) Pore size and fracture ductility of aluminum low pressure die casting. Eng Fract Mech 76:983–996

Dunand M, Mohr D (2011) Optimized butterfly specimen for the fracture testing of sheet materials under combined normal and shear loading. Eng Fract Mech 78:2919–2934

Mohr D, Ebnoether F (2009) Plasticity and fracture of martensitic boron steel under plane stress conditions. Int J Solids Struct 46:3535–3547

Dunand M, Mohr D (2010) Hybrid experimental-numerical analysis of basic ductile fracture experiments for sheet metals. Int J Solids Struct 47:1130–1143

Bornert M, Bremand F, Doumalin P, Dupre J-C, Fazzini M, Grediac M, Hild F, Mistou S, Molimard J, Orteu J-J, Robert L, Surrel Y, Vacher P, Wattrisse B (2009) Assessment of digital image correlation measurement errors: methodology and results. Exp Mech 49(3):353–370

Sutton MA, Orteu JJ, Schreier H (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer

Taylor GI, Quinney H (1932) The Plastic Distortion of Metals; Philosophical Transactions of the Royal Society of London A. 230:323–362

Nouailhas D, Cailletaud G (1995) Tension-torsion behavior of single-crystal superalloys - experiment and finite-element analysis. Int J Plast 11:451–470

Zhang JX, Jiang YY (2005) Luders bands propagation of 1045 steel under multiaxial stress state. Int J Plast 21:651–670

Khan AS, Kazmi R, Pandey A, Stoughton T (2009) Evolution of subsequent yield surfaces and elastic constants with finite plastic deformation. Part-I: A very low work hardening aluminum alloy (Al6061-J6511). Int J Plast 25(9):1611–1625

Khan AS, Pandey A, Stoughton T (2010) Evolution of subsequent yield surfaces and elastic constants with finite plastic deformation. Part-II: A very high work hardening aluminum alloy (annealed 1100 Al). Int J Plast 26(10):1421–1431

Kuwabara T, Yoshida K, Narihara K, Takahashi S (2005) Anisotropic plastic deformation of extruded aluminum alloy tube under axial forces and internal pressure. Int J Plast 21:101–117

Korkolis YP, Kyriakides S, Giagmouris T, Lee LH (2010) Constitutive modeling and rupture predictions of Al-6061-T6 tubes under biaxial loading paths. J Appl Mech Trans ASME 77:064501

Lindholm US, Nagy A, Johnson GR, Hoegleldt JM (1980) Large strain, high-strain rate testing of copper. J Eng Mater Technol Trans ASME 102:376–381

Gao XS, Zhang TT, Zhou J, Graham SM, Hayden M, Roe C (2011) On stress-state dependent plasticity modeling: Significance of the hydrostatic stress, the third invariant of stress deviator and the non-associated flow rule. Int J Plast 27:217–231

Graham SM, Zhang TT, Gao XS, Hayden M (2012) Development of a combined tension-torsion experiment for calibration of ductile fracture models under conditions of low triaxiality. Int J Mech Sci 54:172–181

Haltom SS, Kyriakides S, Ravi-Chandar K (2013) Ductile failure under combined shear and tension. Int J Solids Struct 40:1507–1522

Abaqus (2011) User manuals Version 6.9, Simulia, Providence, USA

Sung JH, Kim JH, Wagoner RH (2010) A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int J Plast 26:1746–1771

Mohr D, Marcadet JM (2013) Hosford-Coulomb Model for predicting the onset of ductile fracture at low stress triaxialities, submitted for publication.

Fischer FD, Kolednik O, Shan GX and Rammerstorfer FG (1995) A Note on Calibration of Ductile Failure Damage Indicators. Int J Fract 73(4):345–357

Acknowledgments

The financial support of Jessica Papasidero through a Monge Fellowship from Ecole Polytechnique is gratefully acknowledged. This work was also supported by the Sésame 2006 grants from the Région Ile-de-France. The partial financial support through the French National Research Agency (Grant ANR-11-BS09-0008, LOTERIE) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Papasidero, J., Doquet, V. & Mohr, D. Determination of the Effect of Stress State on the Onset of Ductile Fracture Through Tension-Torsion Experiments. Exp Mech 54, 137–151 (2014). https://doi.org/10.1007/s11340-013-9788-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9788-4