Abstract

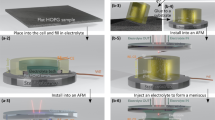

The state-of-the-art cathode materials experience severe structural and mechanical degradation over lithiation cycles albeit their small deformation. It has been a great challenge to characterize the mechanical behavior of composite electrodes in-situ and in real-time because of their environmental sensitivity and intricate microscopic heterogeneity. We use nanoindentation to measure the in-situ mechanical behavior of individual phases in a cathode composite electrode LiNixMnyCozO2. We focus on the understanding of the mechanical properties of the constituents in dry and wet conditions. We evaluate the influence of electrolyte soaking on the elastic modulus, hardness, and volume change of the conductive matrix with different degrees of porosity. More interestingly, we measure the modulus, hardness, and fracture strength of agglomerated active particles and sintered pellets, and compare their mechanical properties in the dry and liquid environment. We show that the electrolyte enhances the fracture strength of NMC agglomerated particles. The increase in interfacial strength may be a result of the additional capillary force between primary particles. Results offer mechanistic understanding of the complex behavior of composite electrodes and will feed chemomechanical models on Li-ion batteries.

Similar content being viewed by others

References

Whittingham MS (2008) Materials challenges facing electrical energy storage. MRS Bull 33:411–419. https://doi.org/10.1557/mrs2008.82

Xu R, Zhao K (2016) Electrochemomechanics of Electrodes in Li-Ion Batteries: A Review. J Electrochem Energy Convers Storage 13:030803. https://doi.org/10.1115/1.4035310

Kusoglu A, Weber AZ (2015) Electrochemical/Mechanical Coupling in Ion-Conducting Soft Matter. J Phys Chem Lett 6:4547–4552. https://doi.org/10.1021/acs.jpclett.5b01639

Wang H, Jang Y, Huang B et al (1999) TEM Study of Electrochemical Cycling-Induced Damage and Disorder in LiCoO2 Cathodes for Rechargeable Lithium Batteries. J Electrochem Soc 146:473–480. https://doi.org/10.1149/1.1391631

Gabrisch H, Yazami R, Fultz B (2002) The Character of Dislocations in LiCoO2. Electrochem Solid-State Lett 5:A111–A114. https://doi.org/10.1149/1.1472257

Kim NY, Yim T, Song JH et al (2016) Microstructural study on degradation mechanism of layered LiNi0.6Co0.2Mn0.2O2 cathode materials by analytical transmission electron microscopy. J Power Sources 307:641–648. https://doi.org/10.1016/j.jpowsour.2016.01.023

Ning G, Haran B, Popov BN (2003) Capacity fade study of lithium-ion batteries cycled at high discharge rates. J Power Sources 117:160–169. https://doi.org/10.1016/S0378-7753(03)00029-6

Miller DJ, Proff C, Wen JG et al (2013) Observation of microstructural evolution in li battery cathode oxide particles by in situ electron microscopy. Adv Energy Mater 3:1098–1103. https://doi.org/10.1002/aenm.201300015

Wang D, Wu X, Wang Z, Chen L (2005) Cracking causing cyclic instability of LiFePO4 cathode material. J Power Sources 140:125–128. https://doi.org/10.1016/J.jpowsour.2004.06.059

Zhao K, Pharr M, Hartle L et al (2012) Fracture and debonding in lithium-ion batteries with electrodes of hollow core-shell nanostructures. J Power Sources 218:6–14. https://doi.org/10.1016/j.jpowsour.2012.06.074

Zhao K, Pharr M, Vlassak JJ, Suo Z (2010) Fracture of electrodes in lithium-ion batteries caused by fast charging. J Appl Phys 108:073517. https://doi.org/10.1063/1.3492617

Jaguemont J, Boulon L, Dubé Y (2016) A comprehensive review of lithium-ion batteries used in hybrid and electric vehicles at cold temperatures. Appl Energy 164:99–114. https://doi.org/10.1016/j.apenergy.2015.11.034

Deshpande R, Verbrugge M, Cheng Y-T et al (2012) Battery Cycle Life Prediction with Coupled Chemical Degradation and Fatigue Mechanics. J Electrochem Soc 159:A1730–A1738. https://doi.org/10.1149/2.049210jes

Pharr M, Suo Z, Vlassak JJ (2013) Measurements of the fracture energy of lithiated silicon electrodes of Li-Ion batteries. Nano Lett 13:5570–5577. https://doi.org/10.1021/nl403197m

Ebner M, Marone F, Stampanoni M, Wood V (2013) Visualization and Quantification of Electrochemical and Mechanical Degradation in Li Ion Batteries. Science (80-) 342:716–721. https://doi.org/10.1126/science.1241882

Cabana J, Monconduit L, Larcher D, Palacín MR (2010) Beyond intercalation-based Li-ion batteries: The state of the art and challenges of electrode materials reacting through conversion reactions. Adv Mater 22:170–192. https://doi.org/10.1002/adma.201000717

Liu XH, Liu Y, Kushima A et al (2012) In situ TEM experiments of electrochemical lithiation and delithiation of individual nanostructures. Adv Energy Mater 2:722–741. https://doi.org/10.1002/aenm.201200024

Beaulieu LY, Eberman KW, Turner RL et al (2001) Colossal Reversible Volume Changes in Lithium Alloys. Electrochem Solid-State Lett 4:A137–A140. https://doi.org/10.1149/1.1388178

Yan P, Zheng J, Gu M et al (2017) Intragranular cracking as a critical barrier for high-voltage usage of layer-structured cathode for lithium-ion batteries. Nat Commun 8:1–9. https://doi.org/10.1038/ncomms14101

Mu L, Lin R, Xu R et al (2018) Oxygen Release Induced Chemomechanical Breakdown of Layered Cathode Materials. Nano Lett 18:3241–3249. https://doi.org/10.1021/acs.nanolett.8b01036

Sun G, Sui T, Song B et al (2016) On the fragmentation of active material secondary particles in lithium ion battery cathodes induced by charge cycling. Extrem Mech Lett 9:449–458. https://doi.org/10.1016/j.eml.2016.03.018

Song B, Sui T, Ying S et al (2015) Nano-structural changes in Li-ion battery cathodes during cycling revealed by FIB-SEM serial sectioning tomography. J Mater Chem A 3:18171–18179. https://doi.org/10.1039/C5TA04151A

Li G, Zhang Z, Huang Z et al (2017) Understanding the accumulated cycle capacity fade caused by the secondary particle fracture of LiNi1-x-yCoxMnyO2 cathode for lithium ion batteries. J Solid State Electrochem 21:673–682. https://doi.org/10.1007/s10008-016-3399-9

Xu R, de Vasconcelos LS, Shi J et al (2018) Disintegration of Meatball Electrodes for LiNixMnyCozO2 Cathode Materials. Exp Mech 58:549–559. https://doi.org/10.1007/s11340-017-0292-0

Cao PF, Naguib M, Du Z et al (2018) Effect of Binder Architecture on the Performance of Silicon/Graphite Composite Anodes for Lithium Ion Batteries. ACS Appl Mater Interfaces 10:3470–3478. https://doi.org/10.1021/acsami.7b13205

Choi S, woo KT, Coskun A, Choi JW (2017) Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science (80- ) 357:279–283. https://doi.org/10.1126/science.aal4373

Xu R, Scalco De Vasconcelos L, Zhao K (2016) Computational analysis of chemomechanical behaviors of composite electrodes in Li-ion batteries. J Mater Res 31:2715–2727. https://doi.org/10.1557/jmr.2016.302

McDowell MT, Ryu I, Lee SW et al (2012) Studying the kinetics of crystalline silicon nanoparticle lithiation with in situ transmission electron microscopy. Adv Mater 24:6034–6041. https://doi.org/10.1002/adma.201202744

Nguyen CC, Yoon T, Seo DM et al (2016) Systematic Investigation of Binders for Silicon Anodes: Interactions of Binder with Silicon Particles and Electrolytes and Effects of Binders on Solid Electrolyte Interphase Formation. ACS Appl Mater Interfaces 8:12211–12220. https://doi.org/10.1021/acsami.6b03357

Iqbal N, Lee S (2018) Mechanical Failure Analysis of Graphite Anode Particles with PVDF Binders in Li-Ion Batteries. J Electrochem Soc 165:A1961–A1970. https://doi.org/10.1149/2.0111810jes

Amanieu H-Y, Rosato D, Sebastiani M et al (2014) Mechanical property measurements of heterogeneous materials by selective nanoindentation: Application to LiMn2O4 cathode. Mater Sci Eng A 593:92–102. https://doi.org/10.1016/j.msea.2013.11.044

de Vasconcelos LS, Xu R, Li J, Zhao K (2016) Grid indentation analysis of mechanical properties of composite electrodes in Li-ion batteries. Extrem Mech Lett 9:495–502. https://doi.org/10.1016/j.eml.2016.03.002

Qu M, Woodford WH, Maloney JM et al (2012) Nanomechanical Quantification of Elastic, Plastic, and Fracture Properties of LiCoO2. Adv Energy Mater 2:940–944. https://doi.org/10.1002/aenm.201200107

Swallow JG, Woodford WH, McGrogan FP et al (2014) Effect of Electrochemical Charging on Elastoplastic Properties and Fracture Toughness of LiXCoO2. J Electrochem Soc 161:F3084–F3090. https://doi.org/10.1149/2.0141411jes

Kim D, Shim HC, Yun TG et al (2016) High throughput combinatorial analysis of mechanical and electrochemical properties of Li[NixCoyMnz]O2 cathode. Extrem Mech Lett 9:439–448. https://doi.org/10.1016/j.eml.2016.03.019

Berla LA, Lee SW, Cui Y, Nix WD (2015) Mechanical behavior of electrochemically lithiated silicon. J Power Sources 273:41–51. https://doi.org/10.1016/j.jpowsour.2014.09.073

Mughal MZ, Moscatelli R, Amanieu HY, Sebastiani M (2016) Effect of lithiation on micro-scale fracture toughness of LixMn2O4 cathode. Scr Mater 116:62–66. https://doi.org/10.1016/j.scriptamat.2016.01.023

Amanieu H-Y, Aramfard M, Rosato D et al (2015) Mechanical properties of commercial LixMn2O4 cathode under different States of Charge. Acta Mater 89:153–162. https://doi.org/10.1016/j.actamat.2015.01.074

Wohlfahrt-Mehrens M, Vogler C, Garche J (2004) Aging mechanisms of lithium cathode materials. J Power Sources 127:58–64. https://doi.org/10.1016/j.jpowsour.2003.09.034

Wang Y, Zhang Q, Li D et al (2018) Mechanical property evolution of silicon composite electrodes studied by environmental nanoindentation. Adv Energy Mater 8:1–8. https://doi.org/10.1002/aenm.201702578

Wendt C, Niehoff P, Winter M, Schappacher FM (2018) Determination of the mechanical integrity of polyvinylidene difluoride in LiNi1/3Co1/3Mn1/3O2 electrodes for lithium ion batteries by use of the micro-indentation technique. J Power Sources 391:80–85. https://doi.org/10.1016/j.jpowsour.2018.03.064

de Vasconcelos LS, Xu R, Zhao K (2017) Operando nanoindentation: a new platform to measure the mechanical properties of electrodes during electrochemical reactions. J Electrochem Soc 164:A3840–A3847. https://doi.org/10.1149/2.1411714jes

Magasinski A, Zdyrko B, Kovalenko I et al (2010) Toward efficient binders for Li-ion battery Si-based anodes: Polyacrylic acid. ACS Appl Mater Interfaces 2:3004–3010. https://doi.org/10.1021/am100871y

Xu R, Sun H, de Vasconcelos LS, Zhao K (2017) Mechanical and Structural Degradation of LiNixMnyCozO2 Cathode in Li-Ion Batteries: An Experimental Study. J Electrochem Soc 164:A3333–A3341. https://doi.org/10.1149/2.1751713jes

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Marshall DB, Lawn BR, Evans AG (1982) Elastic/plastic indentation damage in ceramics: the lateral crack system. J Am Ceram Soc 65:561–566. https://doi.org/10.1111/j.1151-2916.1982.tb10782.x

Chantikul P, Anstis GR, Lawn BR, Marshall DB (1981) A critical evaluation of indentation techniques for measuring fracture toughness: II, strength method. J Am Ceram Soc 64:539–543. https://doi.org/10.1111/j.1151-2916.1981.tb10321.x

Harding DS, Oliver WC, Pharr GM (1994) Cracking During Nanoindentation and its Use in the Measurement of Fracture Toughness. MRS Proc 356:663–668. https://doi.org/10.1557/proc-356-663

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness I. Direct Crack Measurements 46:533–538

Diercks DR, Musselman M, Morgenstern A et al (2014) Evidence for Anisotropic Mechanical Behavior and Nanoscale Chemical Heterogeneity in Cycled LiCoO 2. J Electrochem Soc 161:F3039–F3045. https://doi.org/10.1149/2.0071411jes

Calderon-Moreno J, Popa M (2001) Fracture toughness anisotropy by indentation and SEVNB on tetragonal PZT polycrystals. Mater Sci Eng A 319–321:692–696. https://doi.org/10.1016/S0921-5093(00)02020-7

il JJ, Pharr GM (2008) Influence of indenter angle on cracking in Si and Ge during nanoindentation. Acta Mater 56:4458–4469. https://doi.org/10.1016/j.actamat.2008.05.005

Field JS, Swain MV, Dukino JD (2003) Determination of fracture toughness from the extra penetration produced by indentation pop-in. J Mater Res 18:1412–1416. https://doi.org/10.1557/jmr.2003.0194

Morris DJ, Myers SB, Cook RF (2004) Sharp probes of varying acuity: Instrumented indentation and fracture behavior. J Mater Res 19:165–175. https://doi.org/10.1557/jmr.2004.0020

Scholz T, Schneider GA, Muñoz-Saldaña J, Swain MV (2004) Fracture toughness from submicron derived indentation cracks. Appl Phys Lett 84:3055–3057. https://doi.org/10.1063/1.1711164

Chen Z, Christensen L, Dahn JR (2003) Comparison of PVDF and PVDF-TFE-P as Binders for Electrode Materials Showing Large Volume Changes in Lithium-Ion Batteries. J Electrochem Soc 150:A1073–A1078. https://doi.org/10.1149/1.1586922

Komaba S, Shimomura K, Yabuuchi N et al (2011) Study on polymer binders for high-capacity SiO negative electrode of Li-Ion batteries. J Phys Chem C 115:13487–13495. https://doi.org/10.1021/jp201691g

Chung NK, Kwon YD, Kim D (2003) Thermal, mechanical, swelling, and electrochemical properties of poly(vinylidene fluoride)-co-hexafluoropropylene/poly(ethylene glycol) hybrid-type polymer electrolytes. J Power Sources 124:148–154. https://doi.org/10.1016/S0378-7753(03)00608-6

Liu ZH, Maréchal P, Jérôme R (1998) Blends of poly(vinylidene fluoride) with polyamide 6: interfacial adhesion, morphology and mechanical properties. Polymer (Guildf) 39:1779–1785. https://doi.org/10.1016/S0032-3861(97)00222-X

Chen Z, Christensen L, Dahn JR (2004) Mechanical and Electrical Properties of Poly(vinylidene fluoride–tetrafluoroethylene–propylene)/Super-S Carbon Black Swelled in Liquid Solvent as an Electrode Binder for Lithium-Ion Batteries. J Appl Polym Sci 91:2958–2965

Gu Y-J, Zhang Q-G, Chen Y-B et al (2015) Reduction of the lithium and nickel site substitution in Li1+xNi0.5Co0.2Mn0.3O2 with Li excess as a cathode electrode material for Li-ion batteries. J Alloys Compd 630:316–322. https://doi.org/10.1016/j.jallcom.2014.12.235

Quinn JB, Quinn GD (1997) Indentation brittleness of ceramics: a fresh approach. J Mater Sci 32:4331–4346. https://doi.org/10.1023/A:1018671823059

Ebisu T, Horibe S (2010) Analysis of the indentation size effect in brittle materials from nanoindentation load–displacement curve. J Eur Ceram Soc 30:2419–2426. https://doi.org/10.1016/j.jeurceramsoc.2010.05.006

Kendall K, McN Alford N, Birchall JD et al (1987) Elasticity of Particle Assemblies as a Measure of the Surface Energy of Solids. Source Proc R Soc London Ser A, Math Phys Sci 412:269–283. https://doi.org/10.2307/2398151

Lee MH, Kang YJ, Myung ST, Sun YK (2004) Synthetic optimization of Li[Ni1/3Co1/3Mn1/3]O2 via co-precipitation. Electrochim Acta 50:939–948. https://doi.org/10.1016/j.electacta.2004.07.038

Wu K, Wang F, Gao L et al (2012) Effect of precursor and synthesis temperature on the structural and electrochemical properties of Li(Ni0.5Co0.2Mn0.3)O2. Electrochim Acta 75:393–398. https://doi.org/10.1016/j.electacta.2012.05.035

Reynolds GK, Fu JS, Cheong YS et al (2005) Breakage in granulation: A review. Chem Eng Sci 60:3969–3992. https://doi.org/10.1016/j.ces.2005.02.029

Rumpf H, Schubert H (1974) The behavior of agglomerates under tensile strain. J Chem Eng Japan 7:294–298. https://doi.org/10.1252/jcej.7.294

Jouanneau S, Eberman KW, Krause LJ, Dahn JR (2003) Synthesis, Characterization, and Electrochemical Behavior of Improved Li[NixCo1−2xMnx]O2 (0.1≤x≤0.5). J Electrochem Soc 150:A1637–A1642. https://doi.org/10.1149/1.1622956

Sheng Y (2015) Investigation of electrolyte wetting in lithium ion batteries: effects of electrode pore structures and solution. Dissertation, The University of Wisconsin-Milwaukee

Watanabe S, Kinoshita M, Hosokawa T et al (2014) Capacity fading of LiAlyNi1-x-yCoxO2 cathode for lithium-ion batteries during accelerated calendar and cycle life tests (effect of depth of discharge in charge-discharge cycling on the suppression of the micro-c). J Power Sources 260:50–56. https://doi.org/10.1016/j.jpowsour.2014.02.103

Acknowledgements

We are grateful for the support by the National Science Foundation through the grants DMR-1832707 and CMMI-1726392.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Vasconcelos, L.S., Sharma, N., Xu, R. et al. In-Situ Nanoindentation Measurement of Local Mechanical Behavior of a Li-Ion Battery Cathode in Liquid Electrolyte. Exp Mech 59, 337–347 (2019). https://doi.org/10.1007/s11340-018-00451-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-018-00451-6