Abstract

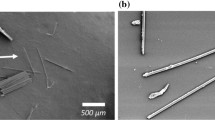

Despite the promise of additive manufacturing (AM) to bring unprecedented agility and design freedom to manufactured components, structural applications remain largely out of reach due to material restrictions – notably the lack of a mature AM process for reinforced thermoset composites. AM is also hindered by process-induced defects such as porosity and unfavorable microstructure. This research shows that a direct write AM process for epoxy / chopped carbon fiber composites can simultaneously achieve a high degree of fiber alignment and low degree of porosity, obtaining 90% of the theoretical tensile modulus and 66% of the theoretical tensile strength for a fully aligned composite. These values exceed those of compression molded properties for the same material. Transverse properties of AM samples were roughly half of the longitudinal properties but showed no statistically significant difference from the matrix material, suggesting that the process may not adversely affect microstructure. The addition of only 5.5 vol% carbon fiber more than doubled the strength and stiffness of the neat epoxy, and more than tripled the properties of ABS thermoplastic while achieving a higher glass transition temperature. Flexural properties show similar trends. SEM and CT imaging shows that fiber orientation is largely maintained in the print direction and cross-section micrographs show there is sufficient local material flow during deposition to achieve low porosity.

Similar content being viewed by others

Notes

SpeedMixer model DAC 150 FVZ, FlackTek Inc., https://speedmixer.com

THINKY model ARV-310, THINKY Corp., https://thinkyusa.com

References

Gibson I, Rosen DW, Stucker B (2010) Additive manufacturing technologies. Springer, New York

Brackett D, Ashcroft I, Hague R (2011) Topology optimization for additive manufacturing. In: Proceedings of the solid freeform fabrication symposium, Austin, TX

Zegard T, Paulino GH (2016) Bridging topology optimization and additive manufacturing. Struct Multidiscip Optim 53(1):175–192. https://doi.org/10.1007/s00158-015-1274-4

Yang S, Tang Y, Zhao YF (2015) A new part consolidation method to embrace the design freedom of additive manufacturing. J Manuf Process 20:444–449. https://doi.org/10.1016/j.jmapro.2015.06.024

Yang S, Zhao YF (2015) Additive manufacturing-enabled design theory and methodology: a critical review. Int J Adv Manuf Technol 80(1):327–342. https://doi.org/10.1007/s00170-015-6994-5

Atzeni E, Salmi A (2012) Economics of additive manufacturing for end-usable metal parts. Int J Adv Manuf Technol 62(9):1147–1155. https://doi.org/10.1007/s00170-011-3878-1

Groover MP (2015) Fundamentals of modern manufacturing: materials, processes, and systems, 6th edn. Wiley, New York

Mai J, Zhang L, Tao F, Ren L (2016) Customized production based on distributed 3D printing services in cloud manufacturing. Int J Adv Manuf Technol 84(1):71–83. https://doi.org/10.1007/s00170-015-7871-y

Kading B, Straub J (2015) Utilizing in-situ resources and 3D printing structures for a manned Mars mission. Acta Astronautica 107:317–326. https://doi.org/10.1016/j.actaastro.2014.11.036

Wong JY (2016) 3D printing applications for space missions. Aerosp Med Hum Perform 87(6):580–582. https://doi.org/10.3357/AMHP.4633.2016

Cozier AD, Harned KE, Riley MA, Raabe BH, Sommers AD, Pierson HA (2015) Additive manufacturing in the design of an engine air particle separator. Proceedings of the ASME 2015 International Mechanical Engineering Congress & Exposition, Houston, TX. Volume 1: advances in aerospace technology. https://doi.org/10.1115/IMECE2015-51592

Boparai KS, Singh R, Singh H (2016) Development of rapid tooling using fused deposition modeling: a review. Rapid Prototyp J 22(2):281–299. https://doi.org/10.1108/RPJ-04-2014-0048

Sun Q, Rizvi GM, Bellehumeur CT, Gu P (2008) Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp J 14(2):72–80. https://doi.org/10.1108/13552540810862028

Pierson HA, Chivukula B (2018) Process–property relationships for fused filament fabrication on preexisting polymer substrates. J Manuf Sci Eng 140(8):084501–084501-084506. https://doi.org/10.1115/1.4039766

Abbott AC, Tandon GP, Bradford RL, Koerner H, Baur JW (2018) Process-structure-property effects on ABS bond strength in fused filament fabrication. Addit Manuf 19:29–38. https://doi.org/10.1016/j.addma.2017.11.002

Oztan C, Karkkainen R, Fittipaldi M, Nygren G, Roberson L, Lane M, Celik E (2018) Microstructure and mechanical properties of three dimensional-printed continuous fiber composites. J Compos Mater 53:271–280. https://doi.org/10.1177/0021998318781938

Dawoud M, Taha I, Ebeid SJ (2016) Mechanical behaviour of ABS: an experimental study using FDM and injection moulding techniques. J Manuf Process 21:39–45. https://doi.org/10.1016/j.jmapro.2015.11.002

Szykiedans K, Credo W, Osinski D (2017) Selected mechanical properties of PETG 3-D prints. Procedia Eng 177:455–461. https://doi.org/10.1016/j.proeng.2017.02.245

Letcher T, Waytashek M (2014) Material property testing of 3d-printed specimen in Pla on an entry-level 3d printer. In: Proceedings of the Asme international mechanical engineering congress and exposition, vol 2a

Brenken B, Barocio E, Favaloro A, Kunc V, Pipes RB (2018) Fused filament fabrication of fiber-reinforced polymers: a review. Addit Manuf 21:1–16. https://doi.org/10.1016/j.addma.2018.01.002

Ning FD, Cong WL, Qiu JJ, Wei JH, Wang SR (2015) Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos Part B 80:369–378. https://doi.org/10.1016/j.compositesb.2015.06.013

Zhong WH, Li F, Zhang ZG, Song LL, Li ZM (2001) Short fiber reinforced composites for fused deposition modeling. Mater Sci Eng A 301(2):125–130. https://doi.org/10.1016/S0921-5093(00)01810-4

Quan ZZ, Larimore Z, Wu A, Yu JY, Qin XH, Mirotznik M, Suhr J, Byun JH, Oh Y, Chou TW (2016) Microstructural design and additive manufacturing and characterization of 3D orthogonal short carbon fiber/acrylonitrile-butadiene-styrene preform and composite. Compos Sci Technol 126:139–148. https://doi.org/10.1016/j.compscitech.2016.02.021

Araya-Calvo M, López-Gómez I, Chamberlain-Simon N, León-Salazar JL, Guillén-Girón T, Corrales-Cordero JS, Sánchez-Brenes O (2018) Evaluation of compressive and flexural properties of continuous fiber fabrication additive manufacturing technology. Addit Manuf 22:157–164. https://doi.org/10.1016/j.addma.2018.05.007

Blok LG, Longana ML, Yu H, Woods BKS (2018) An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit Manuf 22:176–186. https://doi.org/10.1016/j.addma.2018.04.039

Compton BG, Lewis JA (2014) 3D-printing of lightweight cellular composites. Adv Mater 26(34):5930–593+. https://doi.org/10.1002/adma.201401804

Hmeidat NS, Kemp JW, Compton BG (2018) High-strength epoxy nanocomposites for 3D printing. Compos Sci Technol 160:9–20. https://doi.org/10.1016/j.compscitech.2018.03.008

Raney JR, Compton BG, Mueller J, Ober TJ, Shea K, Lewis JA (2018) Rotational 3D printing of damage-tolerant composites with programmable mechanics. Proc Natl Acad Sci U S A 115(6):1198–1203. https://doi.org/10.1073/pnas.1715157115

Ozsoy N, Ozsoy M, Mimaroglu A (2016) Mechanical properties of chopped carbon Fiber reinforced epoxy composites. Acta Phys Pol A 130(1):297–299. https://doi.org/10.12693/APhysPolA.130.297

Koerner H, Misra D, Tan A, Drummy L, Mirau P, Vaia R (2006) Montmorillonite-thermoset nanocomposites via cryo-compounding. Polymer 47(10):3426–3435. https://doi.org/10.1016/j.polymer.2006.03.057

Tandon GP, Weng GJ (1984) The effect of aspect ratio of inclusions on the elastic properties of unidirectionally aligned composites. Polym Compos 5(4):327–333. https://doi.org/10.1002/pc.750050413

Ashby MF (2011) Materials selection in mechanical design, 4th edn. Elsevier, Burlington

Van Hattum F, Bernardo C (1999) A model to predict the strength of short fiber composites. J Polym Comp 20(4):524–533

Ning F, Cong W, Hu Y, Wang H (2017) Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: effects of process parameters on tensile properties. J Compos Mater 51(4):451–462. https://doi.org/10.1177/0021998316646169

Tekinalp HL, Kunc V, Velez-Garcia GM, Duty CE, Love LJ, Naskar AK, Blue CA, Ozcan S (2014) Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos Sci Technol 105:144–150. https://doi.org/10.1016/j.compscitech.2014.10.009

Koerner H, Jacobs J, Tomlin DW, Busbee JD, Vaia R (2004) Tuning polymer nanocomposite morphology: AC electric field manipulation of epoxy–montmorillonite (clay) suspensions. Adv Mater 16(4):297–302

Steger C (1998) An unbiased detector of curvilinear structures. IEEE Trans Pattern Anal Mach Intell 20(2):113–125. https://doi.org/10.1109/34.659930

Vardeman SB (1994) Statistics for engineering problem solving. Thomson Learning EMEA, Limited

HexCel Corp. (2018) HexTow AS4 carbon Fiber product data sheet. https://www.hexcel.com/user_area/content_media/raw/AS4_HexTow_DataSheet.pdf

Zhang SJ, To S (2013) The effects of spindle vibration on surface generation in ultra-precision raster milling. Int J Mach Tools Manuf 71:52–56. https://doi.org/10.1016/j.ijmachtools.2013.04.005

Acknowledgements

The authors would like to acknowledge the financial support for the AFRL Summer Faculty Program, Minority Leaders Program, and International Cooperative Research and Development Fund, as well as the technical contributions from Prof. Brett Compton on ink formulation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pierson, H.A., Celik, E., Abbott, A. et al. Mechanical Properties of Printed Epoxy-Carbon Fiber Composites. Exp Mech 59, 843–857 (2019). https://doi.org/10.1007/s11340-019-00498-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00498-z