Abstract

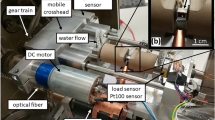

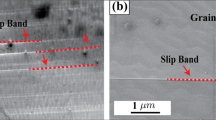

Despite its significance in polycrystalline materials, there have been few experimental investigations of the activity of grain boundary sliding (GBS) and the relationship between GBS and slip transmission at grain boundaries. The present work addresses this knowledge gap by the characterization of full-field strain and microstructural information in an experimental system of high-purity (99.99%) columnar aluminum subjected to uniaxial tension at 190 °C. High-resolution, full-gage strain fields were characterized on an unloaded specimen by distortion-corrected and stitched scanning electron microscope-enabled digital image correlation (SEM-DIC). Alignment between the lower-resolution electron backscatter diffraction (EBSD) and higher-resolution strain fields was significantly improved by clustering of strain data within an EBSD-defined boundary mantle. Grain boundary sliding was investigated at select boundaries, and it was determined that GBS magnitude profiles can have large gradients along a single boundary and vary significantly between boundaries. Using a geometric compatibility factor (m′) to quantify favorability of slip transmission, the two grain boundaries that exhibited the largest average GBS magnitude experienced contiguous slip on moderately well aligned slip systems, although the exact nature of this slip activity, whether transmission or nucleation, remains under investigation.

Similar content being viewed by others

References

Sutton AP, Balluffi RW (2006) Interfaces in Crystalline Materials. Oxford University Press, Oxford

Shen Z, Wagoner RH, Clark WAT (1988) Dislocation and grain boundary interactions in metals. Acta Metall 36:3231–3242. https://doi.org/10.1016/0001-6160(88)90058-2

Lee TC, Robertson IM, Birnbaum HK (1989) Anomalous slip in an FCC system. Ultramicroscopy 29:212–216. https://doi.org/10.1016/0304-3991(89)90248-9

Lee TC, Robertson IM, Birnbaum HK (1990) An In Situ transmission electron microscopy deformation study of the slip transfer mechanisms in metals. Metall Trans A 21:2437–2447. https://doi.org/10.1007/BF02646988

Livingston JD, Chalmers B (1957) Multiple slip in bicrystal deformation. Acta Metall 5:322–327. https://doi.org/10.1016/0001-6160(57)90044-5

Spearot DE, Sangid MD (2014) Insights on slip transmission at grain boundaries from atomistic simulations. Curr Opin Solid St M 18:188–195. https://doi.org/10.1016/j.cossms.2014.04.001

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2004) Deformation-mechanism map for nanocrystalline metals by molecular-dynamics simulation. Nat Mater 3:43–47. https://doi.org/10.1038/nmat1035

Vo NQ, Averback RS, Bellon P, Odunuga S, Caro A (2008) Quantitative description of plastic deformation in nanocrystalline Cu: Dislocation glide versus grain boundary sliding. Phys Rev B 77:134108. https://doi.org/10.1103/PhysRevB.77.134108

Sangid MD, Ezaz T, Sehitoglu H, Robertson IM (2011) Energy of slip transmission and nucleation at grain boundaries. Acta Mater 59:283–296. https://doi.org/10.1016/j.actamat.2010.09.032

Sangid MD, Ezaz T, Sehitoglu H (2012) Energetics of residual dislocations associated with slip-twin and slip-GBs interactions. Mater Sci Eng A 542:21–30. https://doi.org/10.1016/j.msea.2012.02.023

Raman V, Langdon TG (1990) Cyclic Grain Boundary Migration and Sliding in Pure Aluminum. Acta Metall Mater (3):497–507. https://doi.org/10.1016/0956-7151(90)90156-B

Kokawa H, Watanabe T, Karashima S (1981) Sliding behaviour and dislocation structures in aluminium grain boundaries. Philos Mag A 44:1239–1254. https://doi.org/10.1080/01418618108235806

Kumar K, Van Swygenhoven H, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Mater 51:5743–5774. https://doi.org/10.1016/j.actamat.2003.08.032

Mompiou F, Legros M, Bóe A, Coulombier M, Raskin JP, Pardoen T (2013) Inter- and intragranular plasticity mechanisms in ultrafine-grained Al thin films: An in situ TEM study. Acta Mater 61:205–216. https://doi.org/10.1016/j.actamat.2012.09.051

Langdon TG (2006) Grain boundary sliding revisited: Developments in sliding over four decades. J Mater Sci 41:596–609. https://doi.org/10.1007/s10853-006-6476-0

Langdon TG (1994) A unified approach to grain boundary sliding in creep and superplasticity. Acta Metall Mater 42:2437–2443. https://doi.org/10.1016/0956-7151(94)90322-0

Cahn JW, Mishin Y, Suzuki A (2006) Coupling grain boundary motion to shear deformation. Acta Mater 54:4953–4975. https://doi.org/10.1016/j.actamat.2006.08.004

Schiotz J, Di Tolla FD, Jacobsen KW (1998) Softening of nanocrystalline metals at very small grain sizes. Nature 391:561–563. https://doi.org/10.1038/35328

Van Swygenhoven H, Spaczer M, Caro A, Farkas D (1999) Competing plastic deformation mechanisms in nanophase metals. Phys Rev B 60:22–25. https://doi.org/10.1103/PhysRevB.60.22

Van Swygenhoven H, Derlet P (2001) Grain-boundary sliding in nanocrystalline fcc metals. Phys Rev B 64:224105. https://doi.org/10.1103/PhysRevB.64.224105

Sauvage X, Wilde G, Divinski SV, Horita Z, Valiev RZ (2012) Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomena. Mater Sci Eng A 540:1–12. https://doi.org/10.1016/j.msea.2012.01.080

Sabirov I, Murashkin MY, Valiev RZ (2013) Nanostructured aluminum alloys produced by severe plastic deformation: New horizons in development. Mater Sci Eng A 560:1–24. https://doi.org/10.1016/j.msea.2012.09.020

Kammers AD, Wongsa-Ngam J, Langdon TG, Daly S (2014) The effect of microstructure heterogeneity on the microscale deformation of ultrafine-grained aluminum. J Mater Res 29:1664–1674. https://doi.org/10.1557/jmr.2014.207

Moore HF, Betty BB, Dollins CW (1935) The creep and fracture of lead and lead alloys. University of Illinois Bulletin 32:9–50

Valiev RZ, Kaibyshev OA, Astanin VV, Emaletdinov AK (1983) The nature of grain boundary sliding and the superplastic flow. Phys Status Solidi 78:439–448. https://doi.org/10.1002/pssa.2210780209

Bourcier M, Bornert M, Dimanov A, Héripré E, Raphanel JL (2013) Multiscale experimental investigation of crystal plasticity and grain boundary sliding in synthetic halite using digital image correlation. J Geophys Res Solid Earth 118:511–526. https://doi.org/10.1002/jgrb.50065

Carter JLW, Kuper MW, Uchic MD, Mills MJ (2014) Characterization of localized deformation near grain boundaries of superalloy René-104 at elevated temperature. Mater Sci Eng A 605:127–136. https://doi.org/10.1016/j.msea.2014.03.048

Doquet V, Barkia B (2016) Combined AFM, SEM and crystal plasticity analysis of grain boundary sliding in titanium at room temperature. Mech Mater 103:18–27. https://doi.org/10.1016/j.mechmat.2016.09.001

Zhao Y, Toth L, Massion R, Skrotzki W (2018) Role of Grain Boundary Sliding in Texture Evolution for Nanoplasticity. Eng Mater 20:1700212. https://doi.org/10.1002/adem.201700212

Bieler T, Mukherjee A (1990) The High Strain Rate Superplastic Deformation Mechanisms of Mechanically Alloyed Aluminum IN90211. Mater Sci Eng A 128:171–182. https://doi.org/10.1016/0921-5093(90)90225-R

Horton CAP (1970) Some effects of solid solution additions of copper on grain boundary sliding in aluminium. Acta Metall 18:1159–1168. https://doi.org/10.1016/0001-6160(70)90106-9

Huang K, Logé RE (2016) A review of dynamic recrystallization phenomena in metallic materials. J Mater Des 111:548–574. https://doi.org/10.1016/j.matdes.2016.09.012

Kassner ME (1987) Large-Strain Deformation of Aluminum Single Crystals at Elevated Temperature as a Test of the Geometric-Dynamic-Recrystallization Concept. Metall Trans A 20A:2182–2185. https://doi.org/10.1007/BF02650307

Ravichandran N, Prasad YVRK (1991) Dynamic Recrystallization during Hot Deformation of Aluminum: A Study Using Processing Maps. Metall Trans A 22A:2339–2348. https://doi.org/10.1007/BF02665000

Kammers AD, Daly S (2013) Self-Assembled nanoparticle surface patterning for improved digital image correlation in a scanning electron microscope. Exp Mech 53:1333–1341. https://doi.org/10.1007/s11340-013-9734-5

Sutton MA, Li N, Garcia D, Cornille N, Orteu JJ, McNeill SR, Schreier HW, Li X (2006) Metrology in a scanning electron microscope: theoretical developments and experimental validation. Meas Sci Technol 17:2613–2622. https://doi.org/10.1088/0957-0233/17/10/012

Sutton MA, Orteu JJ, Schreier HW (2009) Image Correlation for Shape, Motion and Deformation Measurements. Springer, New York

Chen Z, Lenthe W, Stinville JC, Echlin M, Pollock T, Daly S (2018) High-Resolution Deformation Mapping Across Large Fields of View using Scanning Electron Microscopy and Digital Image Correlation. Exp Mech 58:1407–1421

Doherty PE, Davis RS (1963) Direct Observation of Oxidation of Aluminum Single-Crystal Surfaces. J Appl Phys 1963:34;619–34;628. https://doi.org/10.1063/1.1729318

Jeurgens LPH, Sloof WG, Tichelaar FD, Mittemeijer EJ (2002) Growth kinetics and mechanisms of aluminum-oxide films formed by thermal oxidation of aluminum. J Appl Phys 92:1649–1656. https://doi.org/10.1063/1.1491591

Linne MA, Daly S (2019) Data Clustering for High-Resolution Alignment of Microstructure and Strain Fields (Submitted)

Valiev RZ, Gertsman VY, Kaibyshev OA (1989) Grain Boundary Structure and Properties under External Influences. Phys Status Solidi 97:11–56. https://doi.org/10.1002/pssa.2210970102

Bourdin F, Stinville JC, Echlin MP, Callahan PG, Lenthe WC, Torbet CJ, Texier D, Bridier F, Cormier J, Villechaise P, Pollock TM, Valle V (2018) Measurements of plastic localization by heaviside-digital image correlation. Acta Mater 157:307–325. https://doi.org/10.1016/j.actamat.2018.07.013

Mussot P, Rey C, Zaoui A (1985) Grain Boundary Sliding and Strain Compatibility. Res Mech 14:69–79

Luster J, Morris MA (1995) Compatibility of Deformation in Two-Phase Ti-Al alloys: Dependence on Microstructure and Orientation Relationships. Metall Mater Trans A 26:1745–1756. https://doi.org/10.1007/BF02670762

Bieler TR, Eisenlohr P, Zhang C, Phukan HJ, Crimp MA (2014) Grain boundaries and interfaces in slip transfer. Curr Opinion Solid State Mater Sci 18:212–226. https://doi.org/10.1016/j.cossms.2014.05.003

Chen Z, Daly SH (2017) Active slip system identification in polycrystalline metals by digital image correlation (DIC). Exp Mech 57:115–127. https://doi.org/10.1007/s11340-016-0217-3

Hirth JP, Lothe J (1968) Theory of Dislocations. McGraw-Hill, New York

Namilae S, Chandra N, Nieh TG (2002) Atomistic simulation of grain boundary sliding in pure and magnesium doped aluminum bicrystals. Scr Mater 46:59–54. https://doi.org/10.1016/S1359-6462(01)01195-2

Qi Y, Krajewski PE (2007) Molecular dynamics simulations of grain boundary sliding: The effect of stress and boundary misorientation. Acta Mater 55:1555–1563. https://doi.org/10.1016/j.actamat.2006.10.016

Zaefferer S, Kuo JC, Zhao Z, Winning M, Raabe D (2002) On the influence of grain boundary misorientation on the plastic deformation of aluminum bicrystals. Acta Mater 51:4719–4735. https://doi.org/10.1016/S1359-6454(03)00259-3

Kobayashi S, Tsurekawa S, Watanabe T (2005) Grain boundary hardening and triple junction hardening in polycrystalline molybdenum. Acta Mater 53:1051–1057. https://doi.org/10.1016/j.actamat.2004.11.002

Lim LC, Raj R (1985) The role of residual dislocation arrays in slip induced cavitation, migration and dynamic recrystalization at grain boundaries. Acta Metall 12:2205–2214. https://doi.org/10.1016/0001-6160(85)90182-8

Acknowledgements

This work was supported by the United States Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering under Awards #DE-SC-0013971 and #DE-SC-0014281. The authors gratefully acknowledge Dr. Zhe Chen for his scientific advice and for sharing codes for image and displacement/strain field stitching; Mr. Chris Torbet for helpful scientific discussions, and for his generous assistance in electrical discharge machining of test specimens; Mr. David Bothman for helpful specimen preparation suggestions; and Mr. Mark Cornish and Mr. Darin Randall for helpful discussions and assistance regarding scanning electron microscopy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Linne, M.A., Venkataraman, A., Sangid, M.D. et al. Grain Boundary Sliding and Slip Transmission in High Purity Aluminum. Exp Mech 59, 643–658 (2019). https://doi.org/10.1007/s11340-019-00517-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00517-z