Abstract

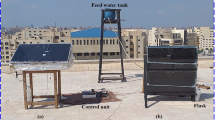

This paper aimed to improve the thermal performance of the stepped solar still. So, the effects of using different types of basin liners (corrugated and curved basin liners), jute cloth wick, CuO/paraffin wax, and vapor suction on the stepped solar still performance were investigated. The CuO/paraffin wax was placed into a groove parallel to the basin steps’ liner. Also, the stepped distiller was integrated with an external condensation unit. The experimental results revealed that using the corrugated and curved liners increased the productivity of the modified stepped solar still (MSSS) by 42% and 33%, respectively. In addition, using the corrugated liner with wick, corrugated liner with wick and CuO/paraffin wax, corrugated liner with wick, CuO/paraffin wax, and vapor suction improved the freshwater productivity of the distiller by 95%, 127%, and 170%, respectively. At the last studied case (MSSS with corrugated liner, wick, CuO/paraffin wax, and vapor suction), the daily freshwater productivities of the MSSS and conventional still (CSS) were 7000 and 2600 mL/m2·day, respectively. Also, the thermal efficiency of MSSS was calculated as 59% which was obtained at the last studied case. And the efficiency of the CSS was 35%. Besides, the distilled water cost of CSS and MSSS with corrugated liner with wick, CuO/paraffin wax, and vapor suction was 0.023 and 0.014 $/L, respectively.

Similar content being viewed by others

Data Availability

Not applicable.

References

Abdelgaied M, Zakaria Y, Kabeel AE, Essa FA (2021) Improving the tubular solar still performance using square and circular hollow fins with phase change materials. Journal of Energy Storage 38:102564

Abderachid T, Abdenacer K (2013) Effect of orientation on the performance of a symmetric solar still with a double effect solar still (comparison study). Desalination 329:68–77

Abdullah AS (2013) Improving the performance of stepped solar still. Desalination 319:60–65

Abdullah AS, Essa FA, Omara ZM, Bek MA (2018) Performance evaluation of a humidification–dehumidification unit integrated with wick solar stills under different operating conditions. Desalination 441:52–61

Abdullah A, Alarjani A, Al-sood MA, Omara Z, Kabeel A, Essa F (2019a) Rotating-wick solar still with mended evaporation technics: experimental approach. Alexandria Engineering Journal 58:1449–1459

Abdullah A, Essa F, Omara Z (2019b) Effect of different wick materials on solar still performance–a review. Int J Ambient Energy:1–28

Abdullah A, Essa F, Omara Z, Rashid Y, Hadj-Taieb L, Abdelaziz G, Kabeel A (2019c) Rotating-drum solar still with enhanced evaporation and condensation techniques: comprehensive study. Energy Convers Manag 199:112024

Abdullah A, Amro M, Younes M, Omara Z, Kabeel A, Essa F (2020a) Experimental investigation of single pass solar air heater with reflectors and turbulators. Alexandria Engineering Journal 59:579–587

Abdullah A, Omara Z, Bek M, Essa F (2020b) An augmented productivity of solar distillers integrated to HDH unit: experimental implementation. Appl Therm Eng 167:114723

Abdullah A, Younes M, Omara Z, Essa F (2020c) New design of trays solar still with enhanced evaporation methods–comprehensive study. Sol Energy 203:164–174

Abdullah AS, Essa FA, Bacha HB, Omara ZM (2020d) Improving the trays solar still performance using reflectors and phase change material with nanoparticles. Journal of Energy Storage 31:101744

Abujazar MSS, Fatihah S, Ibrahim IA, Kabeel AE, Sharil S (2018) Productivity modelling of a developed inclined stepped solar still system based on actual performance and using a cascaded forward neural network model. J Clean Prod 170:147–159

Alawee WH, Mohammed SA, Dhahad HA, Abdullah AS, Omara ZM, Essa FA (2021) Improving the performance of pyramid solar still using rotating four cylinders and three electric heaters. Process Saf Environ Prot 148:950–958

Arani RP, Sathyamurthy R, Chamkha A, Kabeel AE, Deverajan M, Kamalakannan K, Balasubramanian M, Manokar AM, Essa F, Saravanan A (2021) Effect of fins and silicon dioxide nanoparticle black paint on the absorber plate for augmenting yield from tubular solar still. Environ Sci Pollut Res

Arunkumar T, Jayaprakash R, Ahsan A, Denkenberger D, Okundamiya MS (2013) Effect of water and air flow on concentric tubular solar water desalting system. Appl Energy 103:109–115

Attia MEH, Kabeel AE, Abdelgaied M, Essa FA, Omara ZM (2021) Enhancement of hemispherical solar still productivity using iron, zinc and copper trays. Sol Energy 216:295–302

Bait O (2019) Exergy, environ–economic and economic analyses of a tubular solar water heater assisted solar still. J Clean Prod 212:630–646

Boukar M, Harmim A (2004) Parametric study of a vertical solar still under desert climatic conditions. Desalination 168:21–28

El-Agouz SA (2014) Experimental investigation of stepped solar still with continuous water circulation. Energy Convers Manag 86:186–193

El-Samadony Y, Kabeel A (2014a) Theoretical estimation of the optimum glass cover water film cooling parameters combinations of a stepped solar still. Energy 68:744–750

El-Samadony YAF, Kabeel AE (2014b) Theoretical estimation of the optimum glass cover water film cooling parameters combinations of a stepped solar still. Energy 68:744–750

Elsheikh A, Sharshir S, Mostafa ME, Essa F, Ali MKA (2018) Applications of nanofluids in solar energy: a review of recent advances. Renew Sust Energ Rev 82:3483–3502

Essa F, Zhang Q, Huang X, Ibrahim AMM, Ali MKA, Abdelkareem MA, Elagouz A (2017) Improved friction and wear of M50 steel composites incorporated with ZnO as a solid lubricant with different concentrations under different loads. J Mater Eng Perform 1-12

Essa F, Zhang Q, Huang X, Ibrahim AMM, Kamal Ahmed Ali M, Sharshir S (2018) Enhancing the tribological and mechanical properties of M50 steel using solid lubricants–a detailed review. Proc Inst Mech Eng Part J J Eng Tribol 232:619–642

Essa F, Manokar AM, Omara Z, Sathyamurthy R, Kabeel A (2019a) Modified stepped solar still with enhanced evaporation techniques, Twenty-Second International Water Technology Conference, IWTC22, Ismailia

Essa F, Yu J, Elsheikh AH, Tawfik M (2019b) A new M50 matrix composite sintered with a hybrid Sns/Zno nanoscale solid lubricants: an experimental investigation. Materials Research Express 6:116523

Essa F, Elsheikh AH, Sathyamurthy R, Manokar AM, Kandeal A, Shanmugan S, Kabeel A, Sharshir SW, Panchal H, Younes M (2020a) Extracting water content from the ambient air in a double-slope half-cylindrical basin solar still using silica gel under Egyptian conditions. Sustainable Energy Technologies and Assessments 39:100712

Essa F, Omara Z, Abdullah A, Shanmugan S, Panchal H, Kabeel A, Sathyamurthy R, Alawee WH, Manokar AM, Elsheikh AH (2020b) Wall-suspended trays inside stepped distiller with Al2O3/paraffin wax mixture and vapor suction: experimental implementation. Journal of Energy Storage 32:102008

Essa FA, Abd Elaziz M, Elsheikh AH (2020c) Prediction of power consumption and water productivity of seawater greenhouse system using random vector functional link network integrated with artificial ecosystem-based optimization. Process Saf Environ Prot 144:322–329

Essa FA, Abd Elaziz M, Elsheikh AH (2020d) An enhanced productivity prediction model of active solar still using artificial neural network and Harris Hawks optimizer. Appl Therm Eng 170:115020

Essa FA, Abdullah AS, Omara ZM (2020e) Rotating discs solar still: new mechanism of desalination. J Clean Prod 275:123200

Essa FA, Alawee WH, Mohammed SA, Abdullah AS, Omara ZM (2021) Enhancement of pyramid solar distiller performance using reflectors, cooling cycle, and dangled cords of wicks. Desalination 506:115019

Kabeel AE, Omara Z, Essa F (2014a) Improving the performance of solar still by using nanofluids and providing vacuum. Energy Convers Manag 86:268–274

Kabeel AE, Omara Z, Essa F (2014b) Enhancement of modified solar still integrated with external condenser using nanofluids: an experimental approach. Energy Convers Manag 78:493–498

Kabeel AE, Omara ZM, Essa FA, Abdullah AS (2016) Solar still with condenser – a detailed review. Renew Sust Energ Rev 59:839–857

Kabeel A, Omara Z, Essa F, Abdullah A, Arunkumar T, Sathyamurthy R (2017a) Augmentation of a solar still distillate yield via absorber plate coated with black nanoparticles. J Alexandria Engineering Journal 56:433–438

Kabeel AE, Omara Z, Essa F (2017b) Numerical investigation of modified solar still using nanofluids and external condenser. J Taiwan Inst Chem Eng 75:77–86

Mashaly AF, Alazba A, Al-Awaadh A, Mattar MA (2015) Predictive model for assessing and optimizing solar still performance using artificial neural network under hyper arid environment. Sol Energy 118:41–58

Muftah AF, Sopian K, Alghoul MA (2018) Performance of basin type stepped solar still enhanced with superior design concepts. Desalination 435:198–209

Omara ZM, Hamed MH, Kabeel AE (2011) Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 277:281–287

Omara ZM, Kabeel AE, Younes MM (2013) Enhancing the stepped solar still performance using internal reflectors. Desalination 314:67–72

Omara ZM, Kabeel AE, Younes MM (2014) Enhancing the stepped solar still performance using internal and external reflectors. Energy Convers Manag 78:876–881

Omara ZM, Kabeel A, Essa F (2015) Effect of using nanofluids and providing vacuum on the yield of corrugated wick solar still. Energy Convers Manag 103:965–972

Omara ZM, Kabeel AE, Abdullah AS, Essa FA (2016) Experimental investigation of corrugated absorber solar still with wick and reflectors. Desalination 381:111–116

Omara Z, Abdullah A, Kabeel A, Essa F (2017) The cooling techniques of the solar stills’ glass covers–a review. Renew Sust Energ Rev 78:176–193

Omara ZM, Abdullah AS, Essa FA, Younes MM (2021) Performance evaluation of a vertical rotating wick solar still. Process Saf Environ Prot 148:796–804

Panchal H, Nurdiyanto H, Sadasivuni KK, Hishan SS, Essa FA, Khalid M, Dharaskar S, Shanmugan S (2021) Experimental investigation on the yield of solar still using manganese oxide nanoparticles coated absorber. Case Studies in Thermal Engineering 25:100905

Panomwan Na Ayuthaya R, Namprakai P, Ampun W (2013) The thermal performance of an ethanol solar still with fin plate to increase productivity. Renew Energy 54:227–234

Rajaseenivasan T, Kalidasa Murugavel K (2013) Theoretical and experimental investigation on double basin double slope solar still. Desalination 319:25–32

Rajaseenivasan T, Elango T, Kalidasa Murugavel K (2013) Comparative study of double basin and single basin solar stills. Desalination 309:27–31

Sampathkumar K, Arjunan T, Pitchandi P, Senthilkumar P (2010) Active solar distillation—a detailed review. Renew Sust Energ Rev 14:1503–1526

Sarhaddi F, Farshchi Tabrizi F, Aghaei Zoori H, Mousavi SAHS (2017) Comparative study of two weir type cascade solar stills with and without PCM storage using energy and exergy analysis. Energy Convers Manag 133:97–109

Shalaby S, El-Bialy E, El-Sebaii A (2016) An experimental investigation of a v-corrugated absorber single-basin solar still using PCM. Desalination 398:247–255

Shanmugan S, Essa FA, Gorjian S, Kabeel AE, Sathyamurthy R, Muthu Manokar A (2020) Experimental study on single slope single basin solar still using TiO2 nano layer for natural clean water invention. Journal of Energy Storage 30:101522

Srivastava PK, Agrawal SK (2013) Winter and summer performance of single sloped basin type solar still integrated with extended porous fins. Desalination 319:73–78

Suneja S, Tiwari GN (1999) Effect of water depth on the performance of an inverted absorber double basin solar still. Energy Convers Manag 40:1885–1897

Tanaka H, Nakatake Y (2007a) Outdoor experiments of a vertical diffusion solar still coupled with a flat plate reflector. Desalination 214:70–82

Tanaka H, Nakatake Y (2007b) Numerical analysis of the vertical multiple-effect diffusion solar still coupled with a flat plate reflector: optimum reflector angle and optimum orientation of the still at various seasons and locations. Desalination 207:167–178

Yadav YP (1991) Performance analysis of a solar still coupled to a heat exchanger. Desalination 82:243

Younes MM, Abdullah AS, Essa FA, Omara ZM, Amro MI (2021) Enhancing the wick solar still performance using half barrel and corrugated absorbers. Process Saf Environ Prot 150:440–452

Funding

This study is supported by Taif University Researchers Supporting Project number (TURSP-2020/49), Taif University, Taif, Saudi Arabia. The authors would like to thank the Taif University for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Essa, F.A., Omara, Z., Abdullah, A. et al. Augmenting the productivity of stepped distiller by corrugated and curved liners, CuO/paraffin wax, wick, and vapor suctioning. Environ Sci Pollut Res 28, 56955–56965 (2021). https://doi.org/10.1007/s11356-021-14669-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-14669-w