Abstract

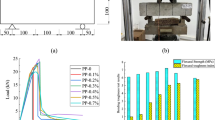

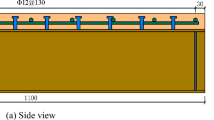

UHTCC (ultrahigh toughness cementitious composite), which is a kind of ultrahigh toughness cementitious composites material, exhibits pseudo strain hardening feature when subjected to tension load, and has enormous ductility and prominent crack dispersal ability. Accordingly, UHTCC can improve mechanical behavior of ordinary concrete structure especially its durability, and has been regarded as historical breakthrough to traditional cementitious materials. In this paper, the study focuses on flexure behavior of steel reinforced beam made of UHTCC. Based on the plane section assumption, along with two equilibrium equations of force and moment, the formulae to calculate the flexural load capability for the reinforced ultrahigh toughness cementitious composite (RUHTCC) beam were developed under the assumption that the compression stress-strain relationship in the UHTCC material is a bilinear model. Following this, the simplified formulae were further evolved by effective rectangle stress distribution approach in order to facilitate design of practical engineering. Two effective parameters introduced in effective rectangle approach were determined. The mathematical expressions to evaluate limited reinforcement ratio, flexural stiffness as well as ductility index were proposed, too. Last, two series of different reinforcement ratios of the RUHTCC beams were tested in four-point flexure loading. For comparison purposes, ordinary RC (reinforced concrete) beams also were prepared. Both moment curvature curves and load mid-span displacement curves were recorded and compared with the theoretical calculations. A good agreement between them was found, which validates the proposed theoretical formulae. For ductility index, a slightly big difference between the experimental values and the calculated ones exists. The experimental results show that, compared to control RC beams, the RUHTCC beam can improve both flexural capacity and ductility index, and the degree of improvement will decrease with the increase in the reinforcement ratio. Particularly, the results also reveal that lager crack width in control beams can be greatly reduced by formation of tightly-spaced fine cracks in UHTCC, which offers more durable structures.

Similar content being viewed by others

References

Feng N Q, Gu Q X, Hao T Y. Cracking in Concrete Structure and Its Countermeasures (in Chinese). Beijing: China Machine Press, 2006

Li C Q. Initiation of chloride-induced reinforcement corrosion in concrete structural member—experimentation. ACI Structure J, 2001, 98(4): 502–510

Perumalsamy N B, Surendra P S. Fiber-reinforced Cement Composites. New York. McGraw-Hill, 1992

Li V C, Leung C K Y. Theory of steady state and multiple cracking of random discontinuous fiber reinforced brittle matrix composites. ASCE J Eng Mech, 1992, 118(11): 2246–2264

Li C, Wu H C. Conditions for pseudo strain-hardening in fiber reinforced brittle matrix composites. J Appl Mech Rev, 1992, 45(8): 390–398

Li V C. From micromechanics to structural engineering — The design of cementitious composites for civil engineering applications. J Struc Mech Earthquake Eng. Japan Society of Civil Engineers, 1993, 37–48

Li V C. On engineered cementitious composites (ECC). J Adv Concrete Tech, 2003; 1(3): 215–229

Xu S L. Report: Research on new ultra-high toughness green cementitious composite and its application (in Chinese). Dalian: Dalian University of Technology, 2007

Li V C, Wang S, Wu C. Tensile strain-hardening behavior of PVAECC. ACI J Struct, 2001, 98(6): 483–492

Li V C, Lepech M. General design assumption for engineered cementitious composites. International Workshop on High Performance Fiber Reinforced Cementitious Composites in Structural Applications. Hawaii, USA, 2005, 5

Mohamed M, Li V C. Intoduction of strain-hardening engineered cementitious composites in design of reinforced concrete flexural members for improved durability. ACI Struc J, 1995; 92(2): 167–176

Wang C Z, Teng Z M. Theory of Reinforced Concrete Structures (in Chinese). Beijing: China Architecture & Building Press, 1985

GB 50010-2002. Concrete Structure Design Code (in Chinese). Beijing: China Architecture & Building Press, 2002

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the Key Program of the National Natural Science Foundation of China (Grant No. 50438010) and the Research and Application Programs of Key Technologies for Major Constructions in the South-North Water Transfer Project Construction in China (Grant No. JGZXJJ2006-13)

Rights and permissions

About this article

Cite this article

Xu, S., Zhang, X. Theoretical analysis and experimental investigation on flexural performance of steel reinforced ultrahigh toughness cementitious composite (RUHTCC) beams. Sci. China Ser. E-Technol. Sci. 52, 1068–1089 (2009). https://doi.org/10.1007/s11431-008-0338-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-008-0338-8