Abstract

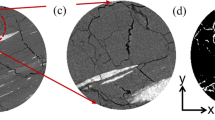

Accurate characterization and visualization of the complex inner structure and stress distribution of rocks are of vital significance to solve a variety of underground engineering problems. In this paper, we incorporate several advanced technologies, such as CT scan, three-dimensional (3D) reconstruction, and 3D printing, to produce a physical model representing the natural coal rock that inherently contains complex fractures or joints. We employ 3D frozen stress and photoelastic technologies to characterize and visualize the stress distribution within the fractured rock under uniaxial compression. The 3D printed model presents the fracture structures identical to those of the natural prototype. The mechanical properties of the printed model, including uniaxial compression strength, elastic modulus, and Poisson’s ratio, are testified to be similar to those of the prototype coal rock. The frozen stress and photoelastic tests show that the location of stress concentration and the stress gradient around the discontinuous fractures are in good agreement with the numerical predictions of the real coal sample. The proposed method appears to be capable of visually quantifying the influences of discontinuous, irregular fractures on the strength, deformation, and stress concentration of coal rock. The method of incorporating 3D printing and frozen stress technologies shows a promising way to quantify and visualize the complex fracture structures and their influences on 3D stress distribution of underground rocks, which can also be used to verify numerical simulations.

Similar content being viewed by others

References

Zhou XG, Cao CJ, Yuan JY (2003) The research actuality and major progresses on the quantitative forecast of reservoir fractures and hydrocarbon migration law. Adv Earth Sci 18:398–404 (in Chinese)

Hou QL, Li HJ, Fan JJ et al (2012) Structure and coalbed methane occurrence in tectonically deformed coals. Sci China Earth Sci 55:1755–1763

Zhang LK, Wang ZL, Qu ZH et al (2007) Physical simulation experiment of gas migration in sandstone porous media. Acta Geol Sin 81:539–544

Mazumder S, Wolf K (2008) Differential swelling and permeability change of coal in response to CO2 injection for ECBM. Int J Coal Geol 74:123–138

Song HZ, Zeng HR, Sun JX et al (1999) Methods of reservoir tectonic fracture prediction and its application. Seismol Geol 21:205–213

Wang J (2014) On area-specific underground research laboratory for geological disposal of high-level radioactive waste in China. J Rock Mech Geotech Eng 6:99–104

White CM, Smith DH, Jones KL et al (2005) Sequestration of carbon dioxide in coal with enhanced coalbed methane recovery—a review. Energy Fuels 19:659–724

Shaika AR, Rahmana SS, Trana NH et al (2011) Numerical simulation of fluid-rock coupling heat transfer in naturally fractured geothermal system. Appl Therm Eng 31:1600–1606

Xu TF, Sampera J, Ayorab C et al (1999) Modeling of non-isothermal multi-component reactive transport in field scale porous media flow systems. J Hydrol 214:144–164

Liu J, Wang H, Nie Y (2004) Fractal model for predicting effective diffusion coefficient of solute in porous media. Adv Water Sci 15:458–462 (in Chinese)

Kim SO, Kim JJ, Yun ST et al (2003) Numerical and experimental studies on cadmium (II) transport in kaolinite clay under electrical fields. Water Air Soil Pollut 150:135–162

Li YS, Yin JM, Ai K (2006) Experimental study of borehole elasticity and geostress in Xiaowan hydropower plant’s dam foundation rock mass. Chin J Undergr Sp Eng 2:912–915 (in Chinese)

Cai YQ, Zhu YW, Li JG et al (2002) Influence of geological flaw on mechanical behaviors of arch dam and dam foundation. Chin J Rock Mech Eng 21:1805–1809 (in Chinese)

Liu X, Fu Y, Wang Y et al (2009) Stability of reservoir bank slope under water–rock interaction. Rock Soil Mech 30:613–616 (in Chinese)

Yang SX, Li H, Bai MZ et al (2010) The wall-rock’s stress releasing regularity arose by cavern excavation in the high stress condition. J China Coal Soc 35:26–30 (in Chinese)

Zhu H, Zhu L, Chen JH et al (2007) The study of deformation and damage mechanism of aluminium alloy (6063) under different stress states. Rare Metal Mater Eng 36:597–601 (in Chinese)

Tarpania JR, Ruckerta, COFT, Milana MT (2004) Estimating fatigue life under variable amplitude loading through quantitative fractography: a case study. Engng Failure Anal 11: 547–559

Zheng ES, Wang ZG, Ai SH (1995) Dislocation structure of fatigue crack tip. Acta Metall Sin 31:105–114 (in Chinese)

Morgeneyer TF, Starink MJ, Sinclair I (2008) Evolution of voids during ductile crack propagation in an aluminium alloy sheet toughness test studied by synchrotron radiation computed tomography. Acta Mater 56:1671–1679

Nelson RA, Handin J (1977) Experimental study of fracture permeability in porous rock. AAPG Bull 61:227–236

Bai M, Roegiers JC, Elsworth D (1995) Poromechanical response of fractured-porous rock masses. J Petrol Sci Eng 13:155–168

Degueldre C, Pleinert H, Maguire P et al (1996) Porosity and pathway determination in crystalline rock by positron emission tomography and neutron radiography. Earth Planet Sci Lett 140:213–225

Liu J, Elsworth D, Brady BH (1999) Linking stress-dependent effective porosity and hydraulic conductivity fields to RMR. Int J Rock Mech Min Sci 36:581–596

Maguire RP, Missimer JH, Emert F et al (1997) Positron emission tomography of large rock samples using a multiring PET instrument. IEEE Trans Nucl Sci 44:26–30

Pingguang X, Tomota Y (2006) Progress in materials characterization technique based on in-situ neutron diffraction. Acta Metall Sin 42:681–688

Dimas LS, Giesa T, Buehler MJ (2014) Coupled continuum and discrete analysis of random heterogeneous materials: elasticity and fracture. J Mech Phys Solids 63:481–490

Farhat C, Avery P, Chapman T et al (2014) Dimensional reduction of nonlinear finite element dynamic models with finite rotations and energy-based mesh sampling and weighting for computational efficiency. Int J Numer Methods Eng 98:625–662

Wang SY, Sloan SW, Sheng DC et al (2014) Numerical study of failure behaviour of pre-cracked rock specimens under conventional triaxial compression. Int J Solids Struct 51:1132–1148

Lisjak A, Liu Q, Zhao Q et al (2013) Numerical simulation of acoustic emission in brittle rocks by two-dimensional finite-discrete element analysis. Geophys J Int 195:423–443

Ghotbi RE, Rahmannejad R, Feili MAE et al (2013) Application of numerical modeling and genetic programming to estimate rock mass modulus of deformation. Int J Min Sci Tech 23:733–737

Hart R (2003) Enhancing rock stress understanding through numerical analysis. Int J Rock Mech Min Sci 40:1089–1097

Yun TS, Jeong YJ, Kim KY et al (2013) Evaluation of rock anisotropy using 3D X-ray computed tomography. Eng Geol 163:11–19

Raynaud S, Fabre D, Mazerolle F et al (1989) Analysis of the internal structure of rocks and characterization of mechanical deformation by a non-destructive method: X-ray tomodensitometry. Tectonophysics 159:149–159

Nasseri MHB, Rezanezhad F, Young RP (2011) Analysis of fracture damage zone in anisotropic granitic rock using 3D X-ray CT scanning techniques. Int J Fract 168:1–13

Mori S, Endo M (2007) Candidate image processing for real-time volumetric CT subtraction angiography. Eur J Radiol 61:335–341

Kawakata H, Cho A, Kiyama T et al (1999) Three-dimensional observations of faulting process in Westerly granite under uniaxial and triaxial conditions by X-ray CT scan. Tectonophysics 313:293–305

Birk M, Dapp R, Ruiter NV et al (2014) GPU-based iterative transmission reconstruction in 3D ultrasound computer tomography. J Parallel Distrib Comput 74:1730–1743

Hajizadeh A, Safekordi A, Farhadpour FA (2011) A multiple-point statistics algorithm for 3D pore space reconstruction from 2D images. Adv Water Resour 34:1256–1267

Gomi T, Koshida K, Miyati T (2007) Development of a non-linear weighted hybrid cone-beam CT reconstruction for circular trajectories. Comput Med Imaging Graph 31:561–569

Geiger J, Hunyadfalvi Z, Bogner P (2009) Analysis of small-scale heterogeneity in clastic rocks by using computerized X-ray tomography (CT). Eng Geol 103:112–118

Ru Z, Ting A, Hegui L et al (2013) 3D reconstruction method and connectivity rules of fracture networks generated under different mining layouts. Int J Min Sci Tech 23:863–871

Rani HP, Divya T, Sahaya RR et al (2013) Numerical investigation of energy and Reynolds stress distribution for a turbulent flow in an orifice. Eng Fail Anal 34:451–463

Jafarian Y, Sadeghi AA, Vakili R et al (2011) On the efficiency and predictability of strain energy for the evaluation of liquefaction potential: a numerical study. Comput Geotech 38:800–808

Latief FDE, Biswal B, Fauzi U et al (2010) Continuum reconstruction of the pore scale microstructure for Fontainebleau sandstone. Phys A: Stat Mech Appl 389:1607–1618

Ju Y, Yang YM, Song ZD et al (2008) A statistical model for porous structure of rocks. Sci China Ser E Technol Sci 51:1026–1041

Hossain MM, Rahman MK (2008) Numerical simulation of complex fracture growth during tight reservoir stimulation by hydraulic fracturing. J Petrol Sci Eng 60:86–104

Ju Y, Wang HJ, Yang YM et al (2010) Numerical simulation of mechanisms of deformation, failure and energy dissipation in porous rock media subjected to wave stresses. Sci China Technol Sci 53:1098–1113

Piri M, Blunt M (2005) Three-dimensional mix-wet random pore-scale network modeling of two- and three-phase flow in porous media. I. Model description. Phys Rev E 71:026301

Pappalettre C, Galietti U (1995) Polycarbonate for frozen stress photoelasticity. Strain 31:69–74

Epstein JS, Post D, Smith CW (1984) Three-dimensional photoelastic measurements with very thin slices. Exp Tech 8:34–37

Schroedl MA, McGowan JJ, Smith CW (1972) An assessment of factors influencing data obtained by the photoelastic stress freezing technique for stress fields near crack tips. Eng Fract Mech 4:801–809

Hyde TH, Warrior NA (1990) An improved method for the determination of photoelastic stress intensity factors using the Westergaard stress function. Int J Mech Sci 32:265–273

Buckberry C, Towers D (1996) New approaches to the full-field analysis of photoelastic stress patterns. Opt Laser Eng 24:415–428

Pinit P, Umezaki E (2007) Digitally whole-field analysis of isoclinic parameter in photoelasticity by four-step color phase-shifting technique. Opt Laser Eng 45:795–807

Baldi A, Bertolino F, Ginesu F (2007) A temporal phase unwrapping algorithm for photoelastic stress analysis. Opt Laser Eng 45:612–617

Kruth JP, Leu MC, Nakagawa T (1998) Progress in additive manufacturing and rapid prototyping. CIRP Ann Manuf Technol 47:525–540

Campbell TA, Ivanova OS (2013) 3D printing of multifunctional nanocomposites. Nano Today 8:119–120

Jee HJ, Sachs E (2000) A visual simulation technique for 3D printing. Adv Eng Softw 31:97–106

Miller BW, Moore JW, Barrett HH et al (2011) 3D printing in X-ray and gamma-ray imaging: a novel method for fabricating high-density imaging apertures. Nucl Instrum Methods Phys Res Sect A 659:262–268

Kostakis V, Papachristou M (2013) Commons-based peer production and digital fabrication: the case of a Rep Rap-based, Lego-built 3D printing-milling machine. Telem Inform 31:434–443

Sun HF, Yang YM, Ju Y et al (2014) Numerical analysis of deformation, failure and energy release mechanisms of fractured coal rock under unloading conditions. J China Coal Soc 39:258–272 (in Chinese)

Ju Y, Xing MX, Sun HF et al (2013) Computer program for extracting and analyzing fractures in rocks and concretes. Software Copyright Registration (#0530646) China’s National Copyright Administration, Beijing (in Chinese)

Ju Y, Zheng JT, Epstein M et al (2014) 3D numerical reconstruction of well-connected porous structure of rock using fractal algorithms. Comput Methods Appl Mech Eng 279:212–226

Ju Y, Zheng JT, Yang YM et al (2012) Computer programs for fractal reconstruction and analysis. Software Copyright Registration (#0449190) China’s National Copyright Administration, Beijing (in Chinese)

Shin DC, Hawong JS (2011) Development of a hybrid method of reflection photoelasticity for crack problems in anisotropic plates. Exp Mech 51:183–198

Dally JW, Riley WF (1991) Experimental stress analysis, 3rd edn. McGraw-Hill, New York

Ramesh K (2000) Digital photoelasticity: advanced techniques and applications. Springer, Berlin

Acknowledgements

This work was supported by the National Natural Science Foundation for Distinguished Young Scholars of China (51125017), the National Natural Science Foundation of China (51374213), and the National Basic Research Program of China (2010CB226804, 2011CB201201).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ju, Y., Xie, H., Zheng, Z. et al. Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin. Sci. Bull. 59, 5354–5365 (2014). https://doi.org/10.1007/s11434-014-0579-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-014-0579-9