Abstract

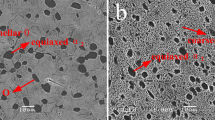

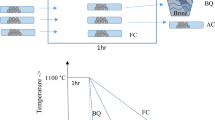

The tensile behavior of Ti-Al-Nb alloys with Al concentrations between 12 and 26 at. pct and Nb concentrations between 22 and 38 at. pct has been investigated for temperatures between 25 °C and 650 °C. Several microstructural features were evaluated in an attempt to identify microstructure-property relationships. In particular, the effects of the phase volume fraction, composition, morphology, and grain size were examined. In addition, the constitutive properties were evaluated using single-phase microstructures, and the results provided insight into the microstructure-property relationships of the two-phase orthorhombic (O)+body-centered-cubic (bcc) microstructures. The disordered fully-bcc (β) Ti-12Al-38Nb microstructure, produced through heat treatment above the β-transus, exhibited a room-temperature (RT) elongation of more than 27 pct and the lowest yield strength (YS-553 MPa) of all the alloys studied. The ordered fully-bcc (B2) microstructures, produced through supertransus heat treatment of near-Ti2AlNb alloys, exhibited fracture strengths up to 672 MPa and low elongations-to-failure (ε f≤0.6 pct). Thus, increasing the Al content, which favors ordering of the bcc structure, significantly reduces the ductility of the bcc phase. Similar to the ordered B2 microstructure, the ordered fully-O Ti2AlNb microstructures exhibited intermediate RT strength (≤704 MPa) and ε f (≤1 pct). The O+bcc microstructures tended to exhibit strengths greater than both the fully-O and fully-bcc microstructures, and this was attributed to the finer grain sizes in the two-phase microstructures compared to their single-phase counterparts. A RT of 1125 MPa was measured for the finest-grained two-phase microstructure. The O+bcc microstructures containing greater bcc-phase volume fractions tended to exhibit greater elongations yet poorer elevated-temperature strengths. A higher Al content typically resulted in larger elevated-temperature strengths. For the Ti-12Al-38Nb bcc-dominated microstructures, fine O platelets, which precipitated during aging, provided significant strengthening and a reduction in ε f for the Ti-12Al-38Nb alloy. However, large RT elongations (ε f>12 pct) were maintained for aged Ti-12Al-38Nb microstructures, which contained 28 vol pct O phase. Morphology did not appear to play a dominant role, as fully-lath and fully-equiaxed two-phase microstructures containing the same phase volume fractions exhibited similar RT tensile properties. The slip and cracking observations provided evidence for the ductile and brittle characteristics of the single-phase microstructures, and the slip compatibility exhibited between the two phases is an important part of why O+bcc microstructures achieve attractive strengths and elongations. The YS vs temperature behavior is discussed in light of other Ti-alloy systems.

Similar content being viewed by others

References

R.G. Rowe, D.G. Konitzer, A.P. Woodfield, and J.C. Chesnutt: in High Temperature Ordered Intermetallic Alloys—IV, L.A. Johnson, D.P. Pope, and J.O. Stiegler, eds., Materials Research Society, Pittsburgh, PA, 1991, vol. 231, pp. 703–08.

R.G. Rowe: in Microstructure/Property Relationships in Titanium Aluminides and Alloys, Y.-W. Kim and R.R. Boyer, eds., TMS, 1991, Warrendale, PA, pp. 387–98.

R.G. Rowe: GE Report No. 93CRD030, Physical Metallurgy Laboratory, Schenectady, NY, 1993.

R.G. Rowe: Titanium ’92 Science and Technology, F.H. Froes and I. Caplan, TMS, Warrendale, PA, 1993, vol. 1, pp. 343–50.

A.K. Gogia, T.K. Nandy, K. Muraleedharan, and D. Banerjee: Mater. Sci. Eng., 1992, vol. A159, pp. 73–86.

R.G. Rowe and M. Larsen: in Titanium ’95, P.A. Blenkinsop, W.J. Evans, and H.M. Flower, eds., The University Press, Cambridge, United Kingdom, 1996, vol. 1, pp. 364–71.

D. Banerjee, A.K. Gogia, T.K. Nandy, K. Muraleedharan, and R.S. Mishra: Structural Intermetallics, R. Darolia, J.J. Lewandowski, C.T. Liu, P.L. Martin, D.B. Miracle, and M.V. Nathal, eds., TMS, Warrendale, PA, 1993, pp. 19–33.

J.C. Chesnutt, R.A. Amato, C.M. Austin, R.L. Fleischer, M.F.X. Gigliotti, D.A. Hardwick, S.C. Huang, D.G. Konitzer, M.M. Lee, P.L. Martin, C.G. Rhodes, R.G. Rowe, G.K. Scarr, D.S. Shih, and P.A. Zomcik: Report No. WL-TR-91-4070, GE Aircraft Engines, Cincinnati, OH, 1993.

B.S. Majumdar, C.J. Boehlert, and D.B. Miracle: Proc. Orthorhombic Titanium Matrix Composites Workshop, Report No. WL-TR-95-4068, Wright-Patterson Air Force Base, OH, 1995, pp. 65–83.

B.S. Majumdar, C.J. Boehlert, A.K. Rai, and D.B. Miracle: in High Temperature Ordered Intermetallic Alloys—VI, J. Horton, I. Baker, S. Hanada, R.D. Noebe, and D.S. Schwartz, eds., Materials Research Society, Pittsburgh, PA, 1995, vol. 364, pp. 1259–65.

P.R. Smith, J.A. Graves, and C.G. Rhodes: Metall. Mater. Trans., 1994, vol. 25A, pp. 1267–83.

P.R. Smith, W.J. Porter, W.J. Kralik, and J.A. Graves: Report No. WL-TR-95-4068, Wright-Patterson Air Force Base, OH, 1994, pp. 371–85.

P.R. Smith, W.J. Porter, W.J. Kralik, and J.A. Graves: Metal Matrix Composites, A. Poursartip and K.N. Street, eds., Woodhead Publishing, Ltd., Cambridge, United Kingdom, 1995, vol. 2, pp. 731–38.

F. Popille and J. Douin: Phil. Mag., 1996, vol. 73, pp. 1401–18.

A.P. Woodfield: Progress Report No. 5, GE Aircraft Engines, Cincinnati, OH, 1996.

F.C. Dary and T.M. Pollock: Mater. Sci. Eng., 1996, vol. A208 (2), p. 188.

F.C. Dary, S.R. Woodard, and T.M. Pollock: in Titanium ’95, P.A. Blenkinsop, W.J. Evans, and H.M. Flower, eds., The University Press, Cambridge, United Kingdom, 1996, vol. 1, pp. 396–403.

S. Emura, J. Liu, M. Hagiwara, Y. Kawabe, and A. Okada: in Titanium ’95, P.A. Blenkinsop, W.J. Evans, and H.M. Flower, eds., The University Press, Cambridge, United Kingdom, 1996, vol. 1, pp. 404–10.

M. Thomas, S. Naka, and T. Khan: in Titanium ’95, P.A. Blenkinsop, W.J. Evans, and H.M. Flower, eds., The University Press, Cambridge, United Kingdom, 1996, vol. 1, pp. 388–95.

F. Popille-Puissochet, A. Courret, and J. Douin: Titanium ’96 Science and Technology, TMS, Warrendale, PA, 1997, pp. 380–87.

C.J. Boehlert, B.S. Majumdar, S. Krishnamurthy, and D.B. Miracle: Metall. Mater. Trans., 1997, vol. 28A, pp. 309–23.

C.J. Boehlert, B.S. Majumdar, and D. Eylon: Key Eng. Mater., 1997, vols. 127–131, part I, pp. 843–50.

C.J. Boehlert, B.S. Majumdar, and V. Seetharaman: Deformation and Fracture of Ordered Intermetallic Materials, W.O. Soboyejo, H.L. Fraser, and T.S. Srivatsan, eds., The Metallurgical Society, Warrendale, PA, 1997, 565–82.

C.J. Boehlert, B.S. Majumdar, V. Seetharaman, and D.B. Miracle: Report No. AFTR WL-TR-97-4082, P.R. Smith, ed., Air Force Research Laboratory, Dayton, OH, 1997, pp. 212–27.

A.K. Gogia, T.K. Nandy, D. Banerjee, T. Carisey, J.L. Strudel, and J.M. Franchet: Intermetallics, 1998, vol. 6, pp. 741–48.

F. Chu, T.E. Mitchell, B.S. Majumdar, D.B. Miracle, T.K. Nandy, and D. Banerjee: Intermetallics, 1997, vol. 5, pp. 147–56.

D. Banerjee: Phil. Mag., 1995, vol. 72 (6), pp. 1159–87.

D. Banerjee, R.G. Rowe, and E.L. Hall: in High Temperature Ordered Intermetallic Alloys—IV, L.A. Johnson, D.P. Pope, and J.O. Stiegler, eds., Materials Research Society, Pittsburgh, PA, 1991, vol. 213, pp. 285–90.

D. Banerjee and R.G. Rowe: in Titanium ’92 Science and Technology F.H. Froes and I. Caplan, eds., TMS, Warrendale, PA, pp. 1147–53.

D. Banerjee, A.K. Gogia, and T.K. Nandy: Metall. Trans., 1990, vol. 21A, pp. 627–39.

A.S. Akkurt: Master’s Thesis, New Mexico Institute of Mining and Technology, Socorro, NM.

C.M. Austin, J.R. Dobbs, H.L. Fraser, D.G. Konitzer, D.J. Miller, M.J. Parks, J.C. Schaeffer, and J.W. Sears: Report No. WL-TR-93-4059, GE Aircraft Engines, Cincinnati, OH, 1992.

J.H. Peng, Y. Mao, S.Q. Li, and X.F. Sun: Trans. Nonferrous Met. Soc. China, 2000, vol. 10 (3), pp. 378–81.

C.J. Boehlert, B.S. Majumdar, V. Seetharaman, and D.B. Miracle: Metall. Mater. Trans., 1999, vol. 30A, pp. 2305–23.

C.J. Boehlert and D.B. Miracle: Metall. Mater. Trans., 1999, vol. 30A, pp. 2349–67.

C.J. Boehlert: Mater. Sci. Eng., 2000, vol. A279 (1–2), pp. 118–29.

C.J. Boehlert and J.F. Bingert: J. Mater. Processing Technol., in press.

A.S. Akkurt, G. Liu, and G.M. Bond: in High-Temperature Ordered Intermetallic Alloys IV, L.A. Johnson, D.P. Pope, and J.O. Stiegler, eds., Materials Research Society, Pittsburgh, PA, 1991, vol. 213, pp. 455–60.

R. Wheeler, S. Perungulam, S. Banerjee, D.H. Hou, R.J. Grylls, and H.L. Fraser: Structural Intermetallics, M.V. Nathal, R. Darolia, C.T. Liu, P.L. Martin, D.B. Miracle, R. Wagner, and M. Yamaguchi, eds., TMS, Warrendale, PA, 1997, pp. 851–58.

A.G. Evans, J.W. Hutchinson, and R.M. McMeeking: Scripta Metall., 1991, vol. 25, pp. 3–8.

G. Bao, J.W. Hutchinson, and R.M. McMeeking: Acta Metall. Mater., 1991, vol. 39(8), pp. 1871–82.

L.C. Davis and J.E. Allison: Metall. Mater. Trans., 1995, vol. 26A, pp. 3081–90.

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, John Wiley & Sons, New York, NY, 1976.

D.B. Miracle: Acta Metall., 1993, vol. 41(3), pp. 649–84.

D. Banerjee: Intermetallic Compounds Principles and Practice, 1994, J.H. Westbrook and R.L. Fleischer, eds., John Wiley & Sons Ltd., New York, NY, vol. 2, pp. 91–131.

C.C. Wojcik, R. Roessler, and R. Zordan: in Advances in the Science and Technology of Titanium Alloy Processing, I. Weiss, P. Bania, and D. Eylon, eds., The Metallurgical Society, Warrendale, PA, 1996.

Y. Mao, S.Q. Li, J.W. Zhang, J.H. Peng, D.X. Zou, and Z.Y. Zhong: Intermetallics, 2000, vol. 8 (5–6), pp. 659–62.

F. Tang, S. Emura, and M. Hasiwara: Scripta. Metall., 2001, vol. 44, pp. 671–6.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Boehlert, C.J. Part III. The tensile behavior of Ti-Al-Nb O+Bcc orthorhombic alloys. Metall Mater Trans A 32, 1977–1988 (2001). https://doi.org/10.1007/s11661-001-0010-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0010-4